Nano-emulsion for fracturing water control and preparation method of nano-emulsion

A technology for nanoemulsions and water, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large particle size, high viscosity, poor physical properties, etc., and achieve low surface tension, low viscosity, and low permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

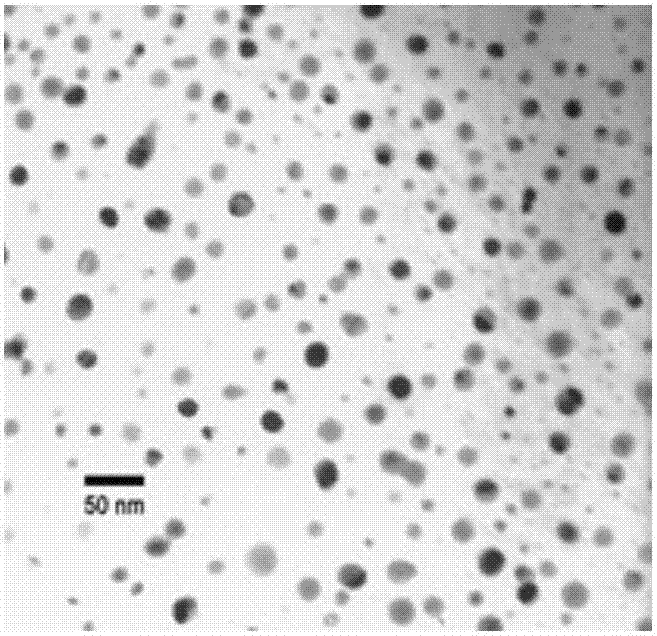

Image

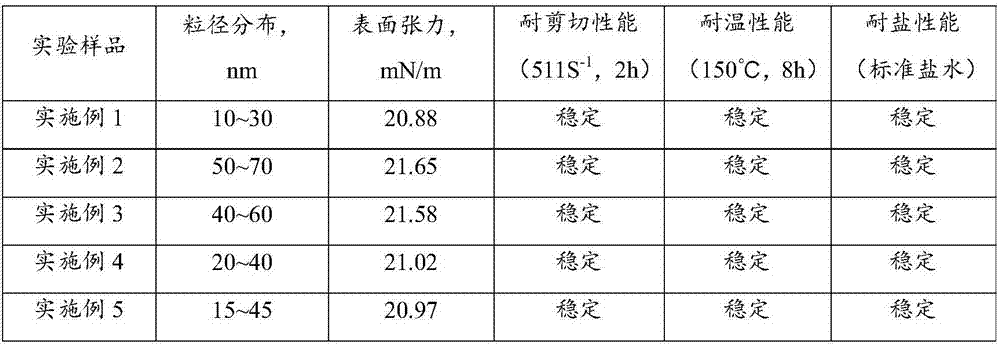

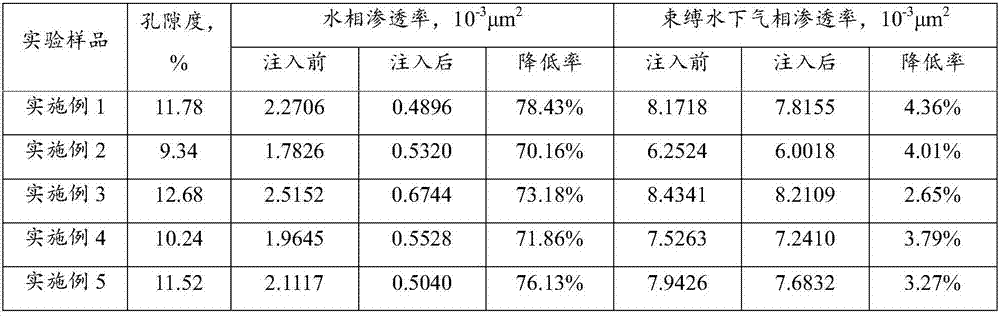

Examples

Embodiment 1

[0058] At room temperature, take 20.0g of dihydroxy polydimethylsiloxane, the hydroxyl content is: 8.0%, the molecular weight is 16000, 5.0g of alkylphenol polyoxyethylene ether NP-10, 2.0g of fatty acid polyoxyethylene ester OEO- 103. Add 5.0g of n-propanol into the dihydroxypolydimethylsiloxane, stir at 100r / min for 30min, and then drop 33.0g of deionized water evenly within 15min at 50℃ under stirring at 400r / min into the oil phase to obtain a transparent and uniform liquid, which is the nanoemulsion for fracturing water control.

Embodiment 2

[0060] At room temperature, take 20.0g of dihydroxy polydimethylsiloxane, the hydroxyl content is: 12.0%, the molecular weight is 50000, 6.2g of alkylphenol polyoxyethylene ether NP-10, 3.0g of fatty acid polyoxyethylene ester OEO- 103. Add 6.0g of n-butanol into dihydroxy polydimethylsiloxane, stir at 100r / min for 30min, and then drop 40.0g of deionized water evenly within 15min at 80℃ under stirring at 800r / min into the oil phase to obtain a transparent and uniform liquid, which is the nanoemulsion for fracturing water control.

Embodiment 3

[0062] At room temperature, take 20.0g of dihydroxy polydimethylsiloxane, the hydroxyl content is: 8.0%, the molecular weight is 50000, 4.0g of alkylphenol polyoxyethylene ether NP-12, 4.0g of fatty acid polyoxyethylene ester OEO- 103. Add 3.0g of n-propylamine into the dihydroxy polydimethylsiloxane, stir at 100r / min for 25min, and then drop 35.0g of deionized water into the In the oil phase, a transparent and uniform liquid is obtained, which is the nanoemulsion for fracturing water control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com