High-performance polyester resin powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as poor bending resistance, weak bonding force of substrates, and unsmooth appearance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

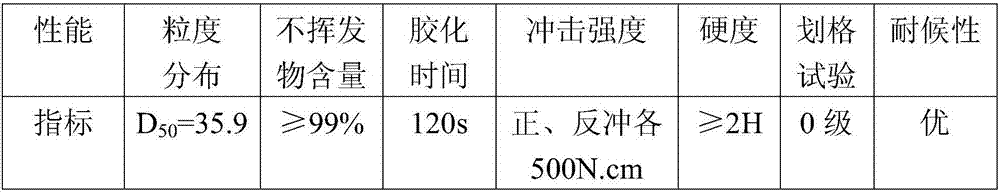

Examples

Embodiment 1

[0014] First, weigh the following components by weight: 35 parts of polyester resin, 10 parts of triglycidyl isocyanurate, 20 parts of rutile titanium dioxide, 10 parts of barium sulfate, 15 parts of calcium carbonate, 5 parts of leveling agent Parts, 5 parts of 1.0% silane coupling agent.

[0015] Then, prepare the coating: weigh each component in proportion, place it in a mixer, crush and mix it for 5-8 minutes, and then place it in a twin-screw extruder with a feeding speed of 1000r / min and a main screw speed of 2500r / min Melt extrusion, while controlling the temperature of the first zone to 90°C and the temperature of the second zone to 100°C, the melted raw materials are placed in a cooling tablet press with a conveyor belt and a tablet press with a speed of 1000r / min, and finally placed in a main mill with a grinding speed of 5000r / min, auxiliary grinding speed 2600r / min grinding system, the grinding particle size of 33 ~ 37um polyester resin powder coating.

Embodiment 2

[0017] First, weigh the following components by weight: 37 parts of polyester resin, 12 parts of triglycidyl isocyanurate, 18 parts of rutile titanium dioxide, 13 parts of barium sulfate, 13 parts of calcium carbonate, and 4 parts of leveling agent Parts, 3 parts of 1.0% silane coupling agent.

[0018] Then, prepare the coating: weigh each component in proportion, place it in a mixer, crush and mix it for 5-8 minutes, and then place it in a twin-screw extruder with a feeding speed of 1000r / min and a main screw speed of 2500r / min Melt extrusion, while controlling the temperature of the first zone to 90°C and the temperature of the second zone to 100°C, the melted raw materials are placed in a cooling tablet press with a conveyor belt and a tablet press with a speed of 1000r / min, and finally placed in a main mill with a grinding speed of 5000r / min, auxiliary grinding speed 2600r / min grinding system, the grinding particle size of 33 ~ 37um polyester resin powder coating.

Embodiment 3

[0020] First, weigh the following components by weight: 40 parts of polyester resin, 15 parts of triglycidyl isocyanurate, 15 parts of rutile titanium dioxide, 15 parts of barium sulfate, 10 parts of calcium carbonate, and 3 parts of leveling agent Parts, 2 parts of 1.0% silane coupling agent.

[0021] Then, prepare the coating: weigh each component in proportion, place it in a mixer, crush and mix it for 5-8 minutes, and then place it in a twin-screw extruder with a feeding speed of 1000r / min and a main screw speed of 2500r / min Melt extrusion, while controlling the temperature of the first zone to 90°C and the temperature of the second zone to 100°C, the melted raw materials are placed in a cooling tablet press with a conveyor belt and a tablet press with a speed of 1000r / min, and finally placed in a main mill with a grinding speed of 5000r / min, auxiliary grinding speed 2600r / min grinding system, the grinding particle size of 33 ~ 37um polyester resin powder coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com