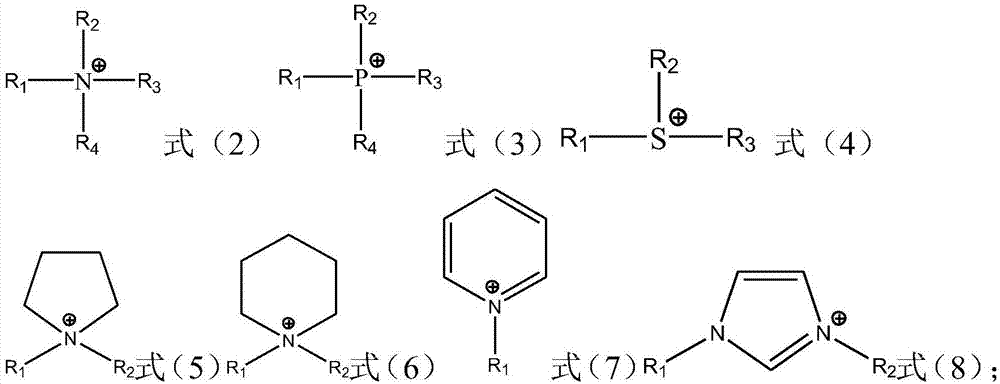

Ionic liquid compound, preparation method thereof, ionic liquid polymer, use of ionic liquid polymer and polymer solid electrolyte containing ionic liquid polymer

A technology of ionic liquids and compounds, applied in the field of polymer solid electrolytes, can solve the problems of slow ion migration and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

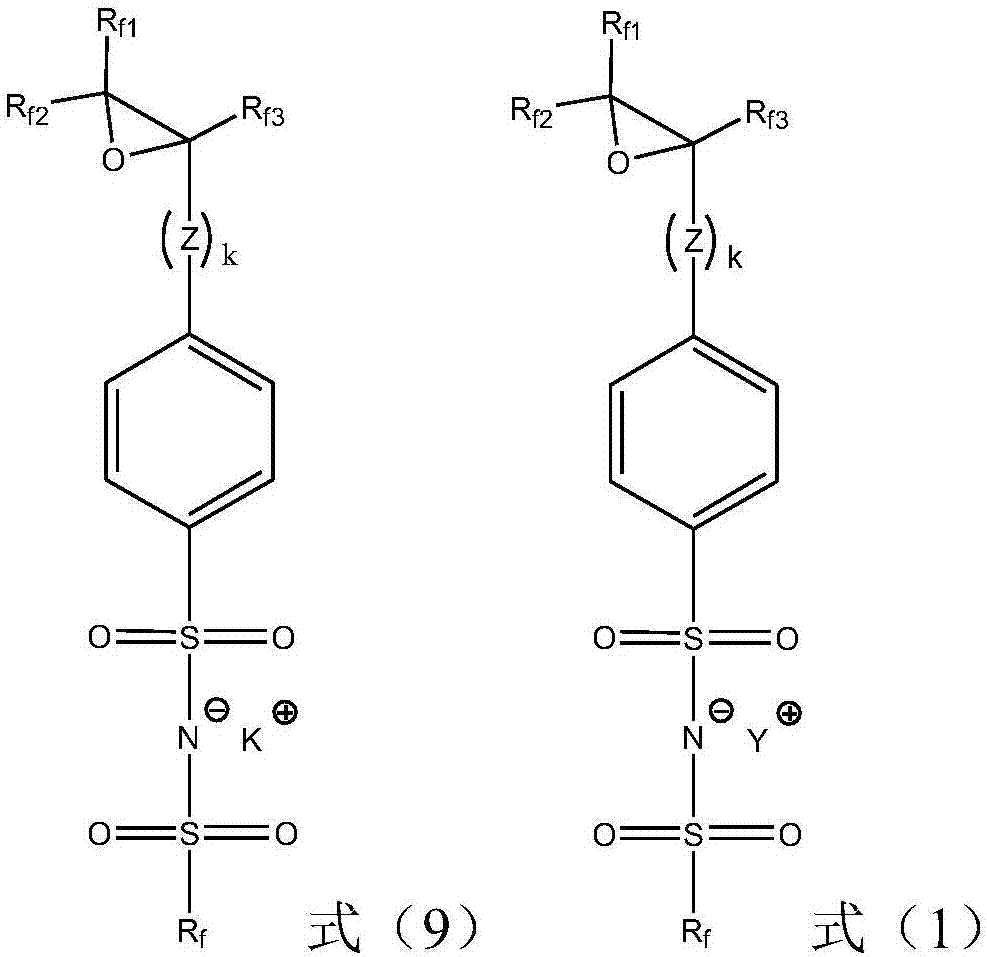

[0065] Optionally, the preparation method of the compound shown in formula (9) comprises: making the compound shown in formula (10) contact with oxidizing agent under oxidation reaction condition:

[0066]

[0067] In formula (10), Z, k, R f1 , R f2 , R f3 and R f has the same definition as above.

[0068] Optionally, the oxidizing agent can be at least one selected from peracetic acid, perbenzoic acid, m-chloroperbenzoic acid and trifluoroperacetic acid, and the molar ratio of the compound shown in formula (10) to the oxidizing agent can be 1 : (1-3).

[0069] Optionally, the conditions of the oxidation reaction are as follows: the reaction temperature is 0-200°C, the reaction time is 1-24h, and the solvent is at least one of toluene, chloroform and dichloromethane.

[0070] Optionally, the preparation method of the compound shown in formula (10) comprises: make the compound shown in formula (11) and the compound shown in formula (12) or the compound shown in formula ...

Embodiment 1

[0174]

[0175] Take 2.0266g (10mmol) of p-vinylbenzenesulfonamide, 2.3794g (20mmol) of thionyl chloride, and 1.3982g (12mmol) of chlorosulfonic acid at 100°C for 12h to obtain compound 1a (2.5357g, yield 90%) ; 1 H NMR (400MHz, CDCl 3 , ppm), δ=7.88(d,2×1H), 7.58(d,2×1H), 6.63(q,1H), 5.61(q,1H), 5.18(q,1H), 2.0(s,1H );

[0176] Take 2.8174g (10mmol) of compound 1a and 2.1451g (12mmol) of SbF 3 Reacted at 60°C for 12h to obtain compound 1b (2.3875g, yield 90%); 1 H NMR (400MHz, CDCl 3 , ppm), δ=7.88(d,2×1H), 7.58(d,2×1H), 6.63(q,1H), 5.61(q,1H), 5.18(q,1H), 2.0(s,1H );

[0177] Take 2.6528g (10mmol) of compound 1b and 1.3812g (10mmol) PhCO 3 H, 1.3821g (10mmol)K 2 CO 3 Reacted at 25°C for 12h to obtain compound 1c (2.8743g, yield 90%); 1 H NMR (400MHz, CDCl 3, ppm), δ=7.86(d,2×1H), 7.47(d,2×1H), 3.82(t,1H), 2.83(d,2H);

[0178] Take 3.1937g (10mmol) of compound 1c and 1.6128g (11mmol) of 1-ethyl-3-methylimidazole chloride to react at 25°C for 12h to obtain the i...

Embodiment 2

[0180]

[0181] Take 1.8718g (10mmol) of potassium trifluoromethanesulfonamide monohydrogen and react with 2.2293g (11mmol) of p-vinylbenzenesulfonyl chloride at 80°C for 12h to obtain compound 2a (2.8376g, yield 90%); 1 H NMR (400MHz, CDCl 3 , ppm), δ=7.88(d,2×1H), 7.58(d,2×1H), 6.63(q,1H), 5.61(q,1H), 5.18(q,1H), 2.0(s,1H );

[0182] Take 3.1529g (10mmol) of compound 2a and 1.3812g (10mmol) PhCO 3 H, 1.3821g (10mmol)K 2 CO 3 Reacted at 25°C for 12h to obtain compound 2b (3.3244g, yield 90%); 1 H NMR (400MHz, CDCl 3 , ppm), δ=7.86(d,2×1H), 7.47(d,2×1H), 3.82(t,1H), 2.83(d,2H);

[0183] 3.6938g (10mmol) of compound 2b was reacted with 1.6128g (11mmol) of 1-ethyl-3-methylimidazole chloride at 25°C for 12h to obtain the ionic liquid compound M2 of this example (3.9731g, yield 90 %); 1 H NMR (400MHz, CDCl 3 , ppm), δ=8.94(s,1H), 7.86(d,2×1H), 7.74(s,1H), 7.67(s,1H), 7.47(d,2×1H), 4.38(q,2H ), 4.03(s,3H), 3.82(t,1H), 2.83(d,2H), 1.56(t,3H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com