Diatomite building thermal insulation material

A technology of building thermal insulation and diatom mud, which is applied in the field of building materials, can solve the problems of poor thermal insulation performance, high environmental protection value, and low strength, and achieve good heat storage and thermal insulation performance, good production processability, and high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A diatom mud building insulation material:

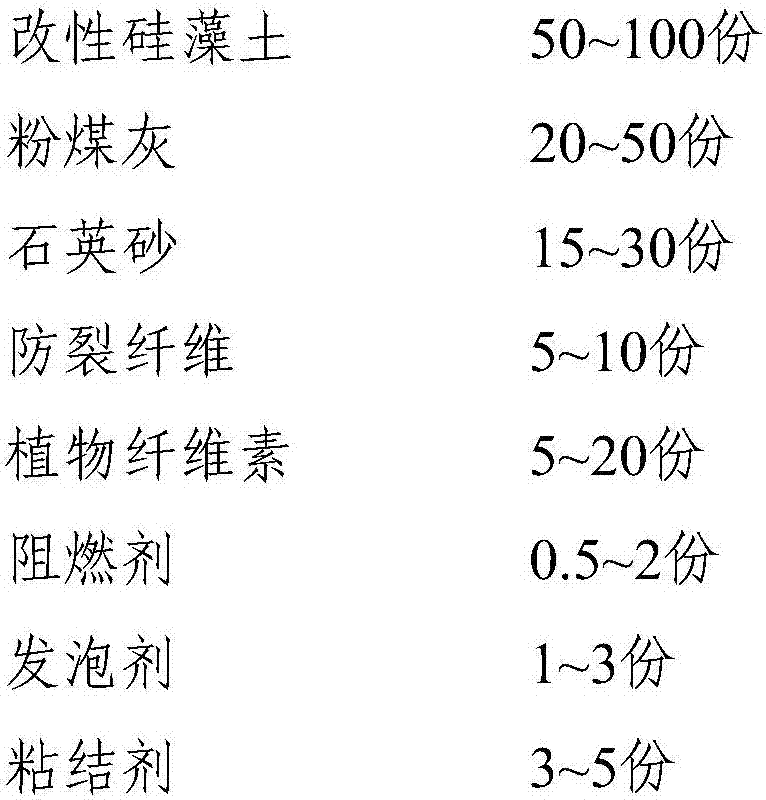

[0029] Formula: include the following components by weight:

[0030]

[0031] The preparation method of modified diatomite is as follows: first, calcinate diatomite in a calciner at 500°C for 1 hour, then take out and cool, pickle, wash with water, filter, dry, and grind into 300-mesh powder modified diatomite earth.

[0032] Preparation:

[0033] (1) Weigh 50 parts of modified diatomite, 20 parts of fly ash, 15 parts of quartz sand, and 5 parts of waste paper powder in parts by weight, add them to the mixer, stir and mix to obtain mixture A;

[0034] (2) Put the mixture A obtained in step (1) into the reactor, add the corresponding amount of water according to the mass ratio of mixture A to water 1:1.1, heat to 60°C and stir for 20 minutes, and then slowly mix according to the weight ratio Add 5 parts of methyl cellulose, 0.5 parts of ammonium polyphosphate, 1 part of sodium dodecylbenzenesulfonate and 3 parts of polyu...

Embodiment 2

[0037] A diatom mud building insulation material:

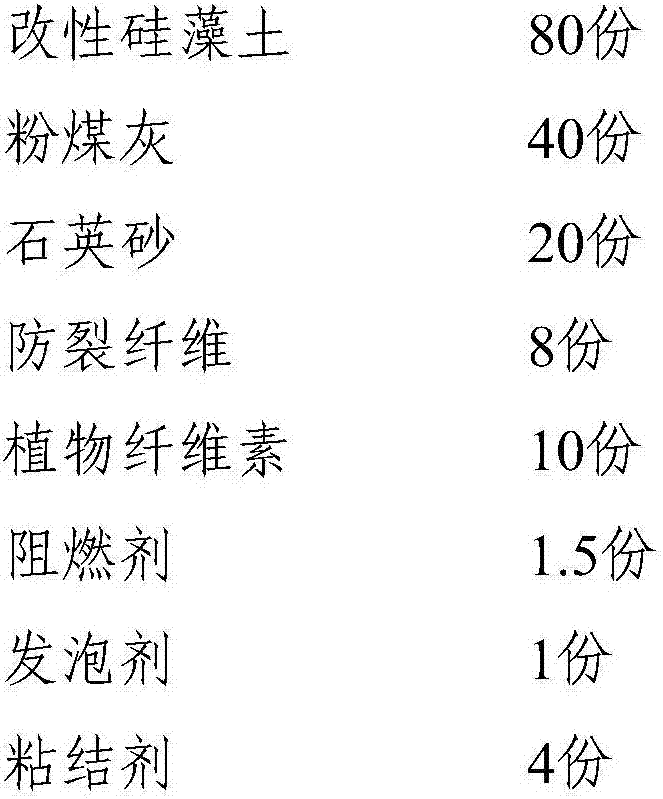

[0038] Formula: include the following components by weight:

[0039]

[0040] The preparation method of modified diatomite is as follows: first, calcinate diatomite in a calciner at 700°C for 2 hours, then take it out for cooling, pickling, washing with water, filtering, drying, and grinding into 500-mesh powder modified diatomite earth.

[0041] Preparation:

[0042] (1) Weigh 100 parts of modified diatomite, 50 parts of fly ash, 30 parts of quartz sand, and 10 parts of aluminum silicate fiber in parts by weight, add them to the mixer, stir and mix them evenly to obtain mixture A;

[0043] (2) Put the mixture A obtained in step (1) into the reactor, add the corresponding amount of water according to the mass ratio of mixture A to water 1:1.3, heat to 80°C and stir for 30min, then slowly mix according to the weight ratio Add 20 parts of hydroxymethyl cellulose, 2 parts of aluminum hydroxide, 3 parts of dodecyl dimethyl ...

Embodiment 3

[0046] A diatom mud building insulation material:

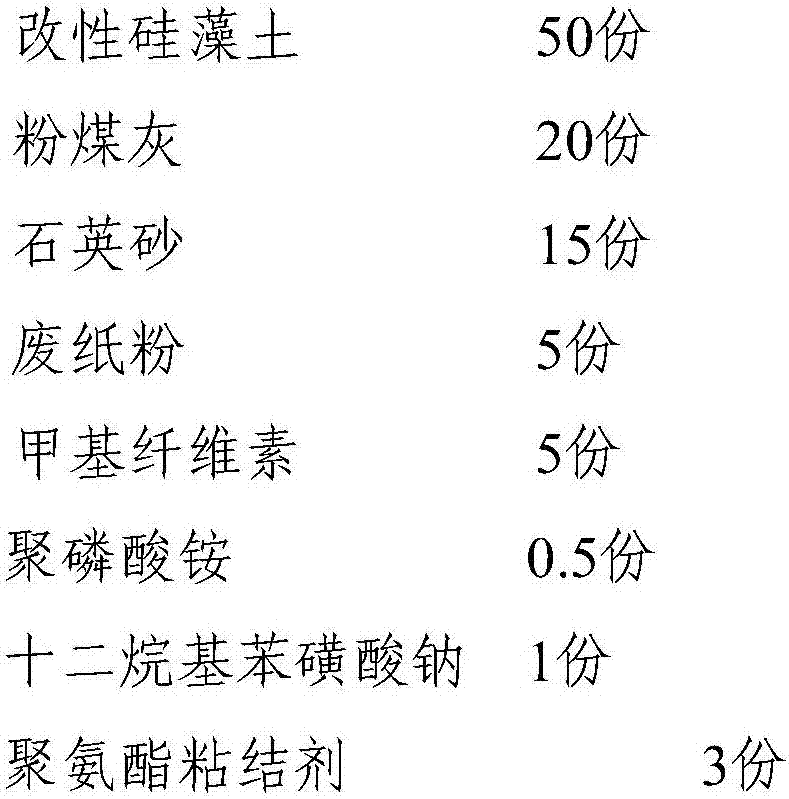

[0047] Formula: include the following components by weight:

[0048]

[0049] The preparation method of modified diatomite is as follows: first, calcinate diatomite in a calciner at 600°C for 1.5 hours, then take it out for cooling, pickling, washing with water, filtering, drying, and grinding into 400-mesh powder modified diatomite earth.

[0050] Preparation:

[0051] (1) Weigh 80 parts of modified diatomite, 40 parts of fly ash, 20 parts of quartz sand, and 8 parts of ceramic fiber by weight, add them to the mixer, stir and mix them evenly to obtain mixture A;

[0052] (2) Put the mixture A obtained in step (1) into the reactor, add the corresponding amount of water according to the mass ratio of mixture A to water 1:1.2, heat to 70°C and stir for 25 minutes, then slowly mix according to the weight ratio Add 5 parts of hydroxypropyl cellulose, 8 parts of hydroxyethyl cellulose, 1 part of magnesium hydroxide, 1 part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com