Method for Selective Passivation of Transalkylation Catalysts

A technology of transalkylation and catalyst, which is applied in the direction of catalyst, catalyst protection, molecular sieve catalyst, etc. It can solve the problems of obvious side reaction of benzene ring hydrogenation and high hydrogen consumption of reaction, and achieve the effect of suppressing excessive hydrogenation side reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

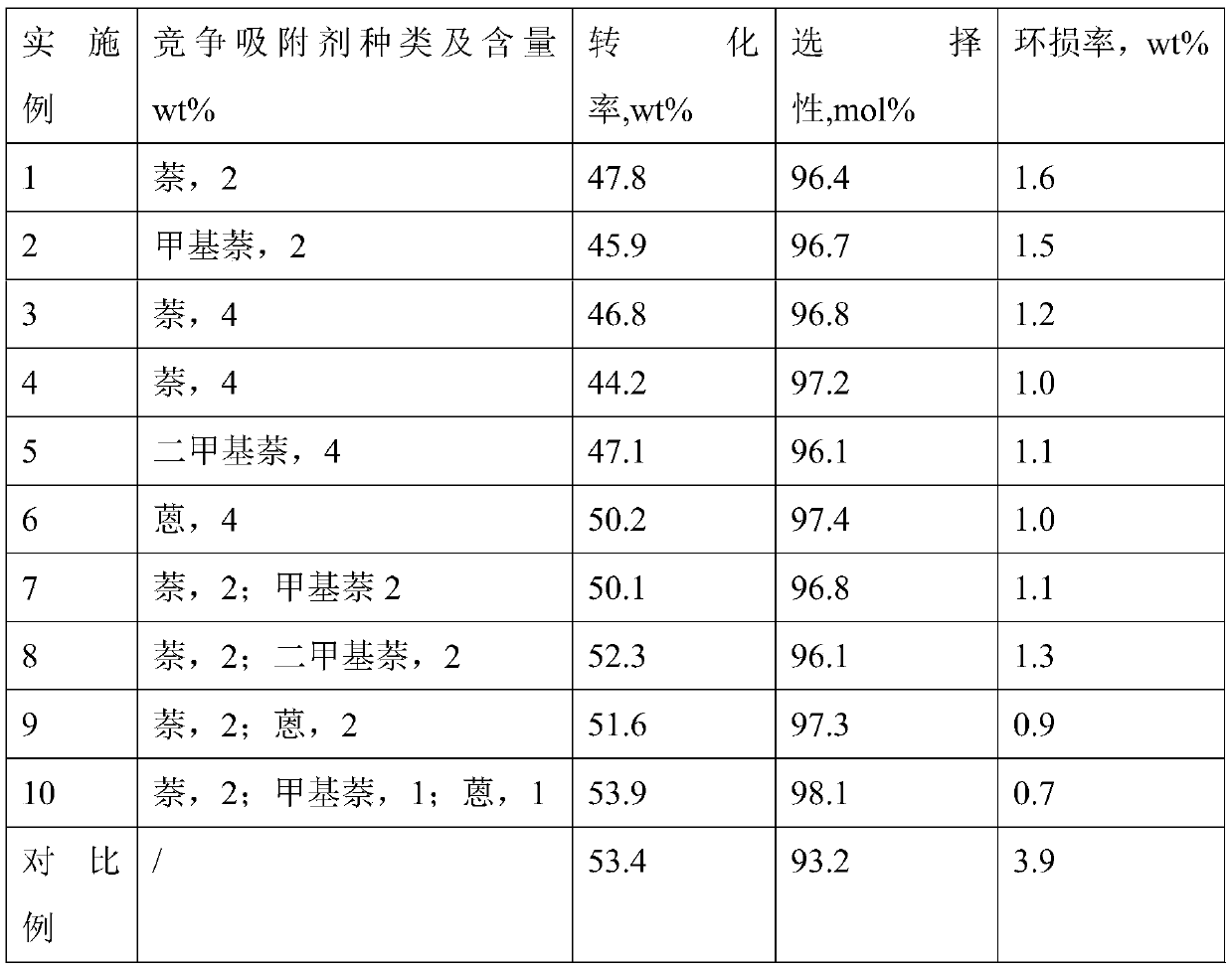

Examples

Embodiment 1

[0017] Na 2 O content is less than 0.1% (weight) MOR molecular sieve 67 grams and with Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O 57.1 grams are uniformly mixed, then added a certain amount of dilute nitric acid and Tian Qing powder, kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after dicing. A certain amount of chloroplatinic acid was dissolved in water, impregnated on the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to obtain catalyst A

[0018] In a fixed-bed reactor, 10 grams of catalyst A was installed, hydrogen gas was passed through, the temperature was raised to 400° C., the reduction activation was carried out by purging for 2 hours, and then selective passivation treatment was carried out. The passivation conditions are: the reaction temperature is 380°C, the pressure is 2.0MPa, and the feed WHSV=3h -1 , the molecular ratio of hydrogen to hydro...

Embodiment 2

[0020] In a fixed-bed reactor, 10 grams of catalyst A was installed, hydrogen gas was passed through, the temperature was raised to 400° C., the reduction activation was carried out by purging for 2 hours, and then selective passivation treatment was carried out. The passivation conditions are: the reaction temperature is 380°C, the pressure is 2.0MPa, and the feed WHSV=3h -1 , the molecular ratio of hydrogen to hydrocarbon is 4.0, and the weight composition of raw material is toluene / C 9 + A=50 / 50, material C 9 + A contains 2% methylnaphthalene. C 9 A raw material weight composition is: 4.2% of propylbenzene, 29.04% of methyl ethylbenzene, 59.6% of trimethylbenzene. After 100 hours of passivation, switch to normal reaction conditions: the reaction temperature is 360°C, the pressure is 3.0MPa, and the feed WHSV=4h -1 , the molecular ratio of hydrogen to hydrocarbon is 2.0, and the weight composition of raw material is toluene / C 9 + A=50 / 50, material C 9 + The content...

Embodiment 3

[0022] In a fixed-bed reactor, 10 grams of catalyst A was installed, hydrogen gas was passed through, the temperature was raised to 400° C., the reduction activation was carried out by purging for 2 hours, and then selective passivation treatment was carried out. The passivation conditions are: the reaction temperature is 410°C, the pressure is 2.0MPa, and the feed WHSV=3h -1 , the molecular ratio of hydrogen to hydrocarbon is 4.0, and the weight composition of raw material is toluene / C 9 + A=50 / 50, material C 9 + A contains 4% naphthalene. C 9 A raw material weight composition is: 4.2% of propylbenzene, 29.04% of methyl ethylbenzene, 59.6% of trimethylbenzene. After 100 hours of passivation, switch to normal reaction conditions: the reaction temperature is 360°C, the pressure is 3.0MPa, and the feed WHSV=4h -1 , the molecular ratio of hydrogen to hydrocarbon is 2.0, and the weight composition of raw material is toluene / C 9 + A=50 / 50, material C 9 + The content of na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com