Preparation method of single-walled carbon nano-tube with adjustable diameter

A carbon nanotube and carbon source technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of large changes in purity, affecting the application of single-wall carbon nanotubes, affecting the determination and application of single-wall carbon nanotubes, etc. , to achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

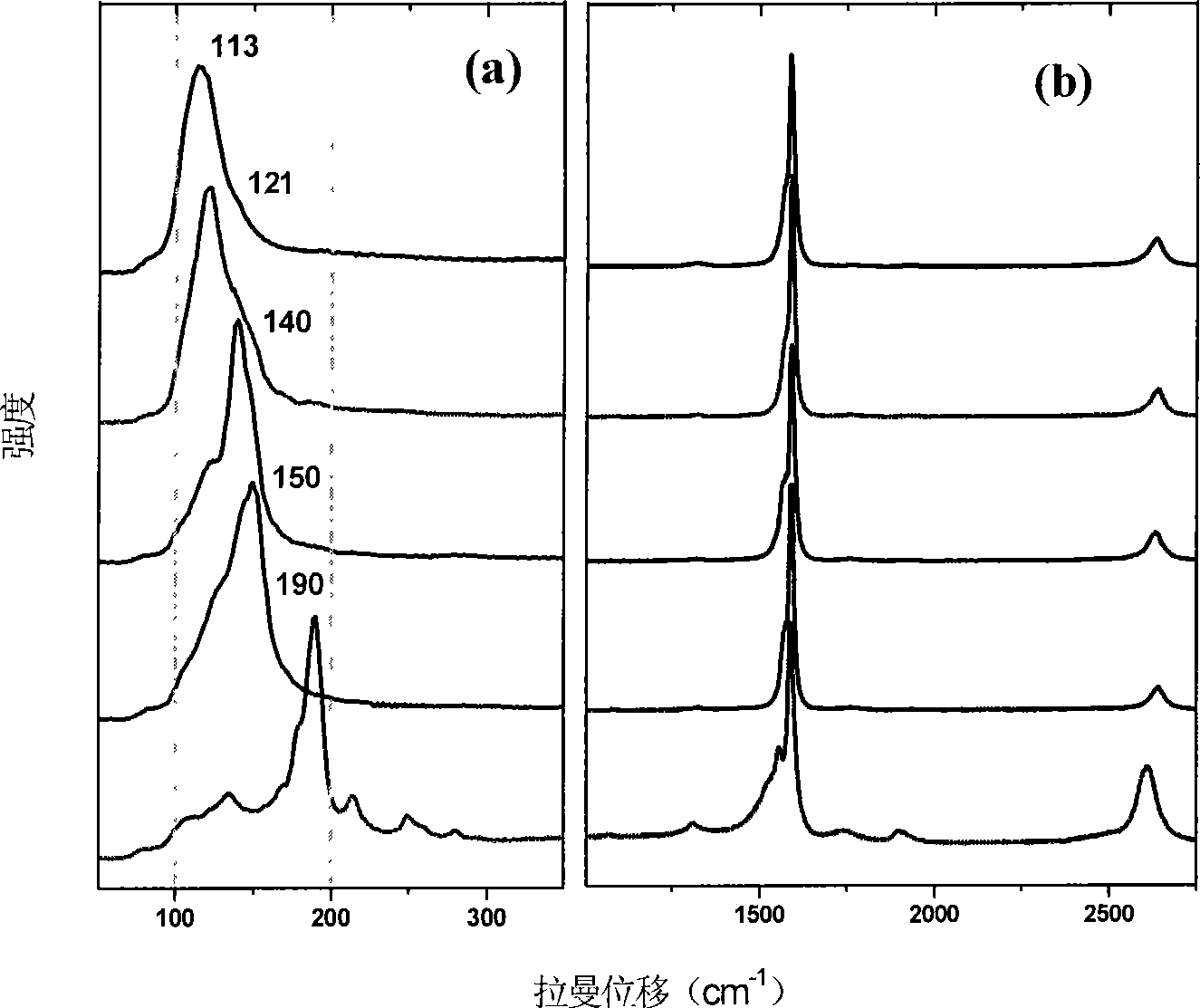

[0022] The carrier gas (buffer gas) hydrogen flow rate is 2.6cm / s, the carbon source methane flow rate is 0.005cm / s, the catalyst is ferrocene, and the sulfur-containing growth promoter is thiophene (C 4 h 4 S), the molar ratio of sulfur to iron is 1:35, the volatilization temperature of the catalyst is 120° C., the temperature of the reaction zone is 1100° C., the heating rate is 20° C. / min, and the temperature is kept for 5 minutes.

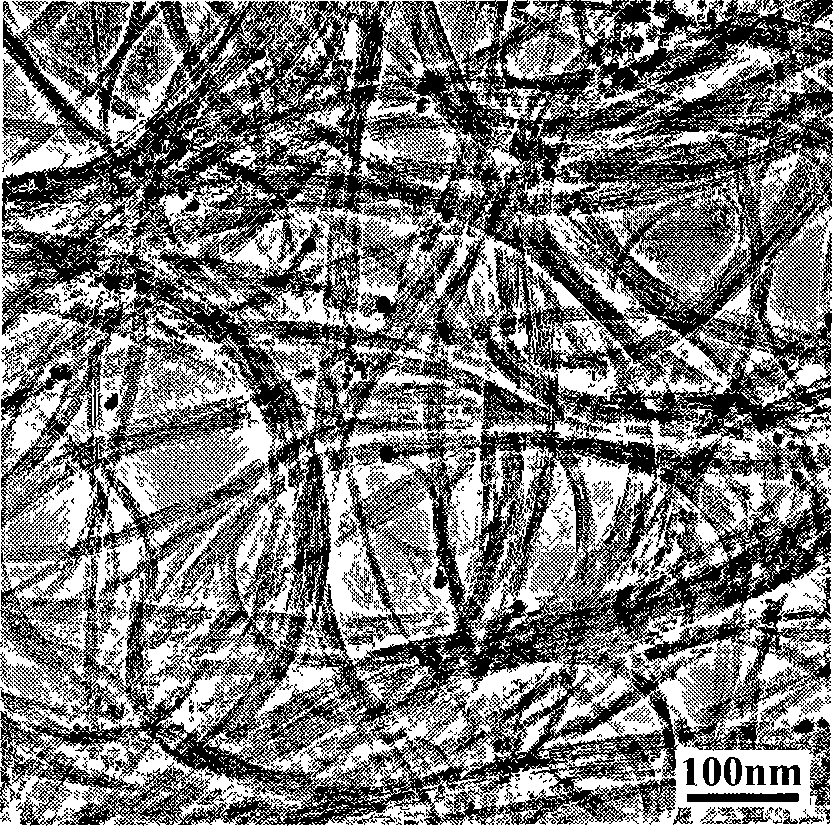

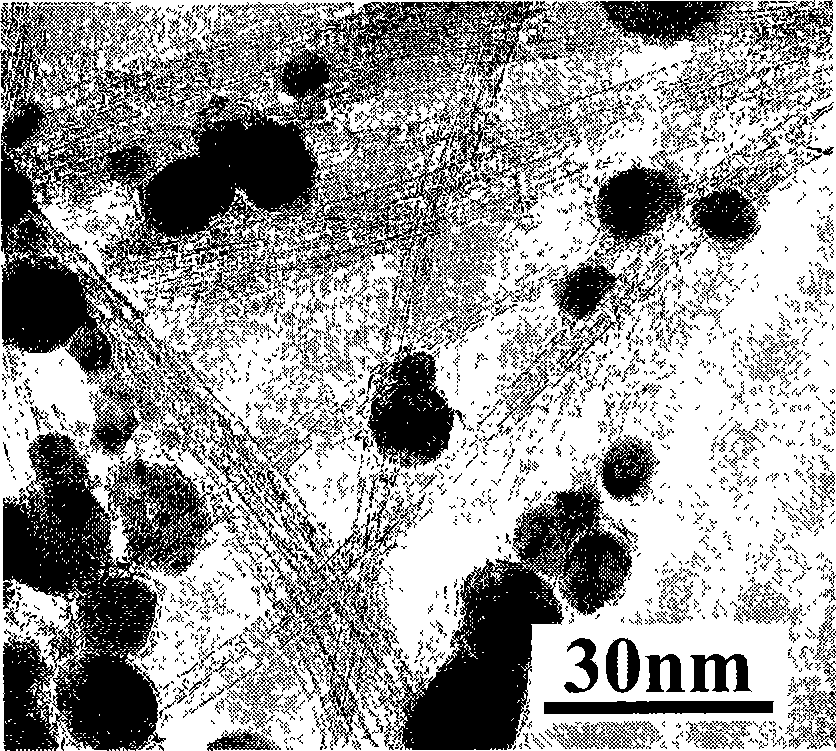

[0023] Observation under the transmission electron microscope ( figure 1 ) shows that the product is very pure and has less impurity content; observation of high-magnification projection photos shows that the product is a single-walled carbon nanotube ( figure 2 ); in this embodiment, the diameters of the single-walled carbon nanotubes are in the range of 1.8±0.2nm, and the purity of the single-walled carbon nanotubes is 40-80wt%.

Embodiment 2

[0025] The carrier gas is a mixed gas of hydrogen and argon (the molar ratio is 2:1). Thiophene (C 4 h 4 S), the molar ratio of sulfur to iron is 1:35, the volatilization temperature of the catalyst is 80° C., the temperature of the reaction zone is 1100° C., the heating rate is 30° C. / min, and the heat preservation is 50 minutes.

[0026] Observation under an electron microscope showed that the product was single-walled carbon nanotubes; in this embodiment, the diameters of the single-walled carbon nanotubes were within the range of 1.6±0.2 nm, and the purity of the single-walled carbon nanotubes was 40-80 wt%.

Embodiment 3

[0028] The carrier gas hydrogen flow rate is 3.2cm / s, the carbon source ethylene flow rate is 0.005cm / s, the catalyst is nickelocene, and the sulfur-containing growth promoter is carbon disulfide (CS 2 ), the molar ratio of sulfur to iron was 1:15, the volatilization temperature of the catalyst was 60°C, the temperature of the reaction zone was 1100°C, the heating rate was 40°C / min, and the heat preservation was 125min.

[0029] Observation under an electron microscope showed that the product was single-walled carbon nanotubes; in this embodiment, the diameters of the single-walled carbon nanotubes were within the range of 2.0±0.2 nm, and the purity of the single-walled carbon nanotubes was 40-80 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com