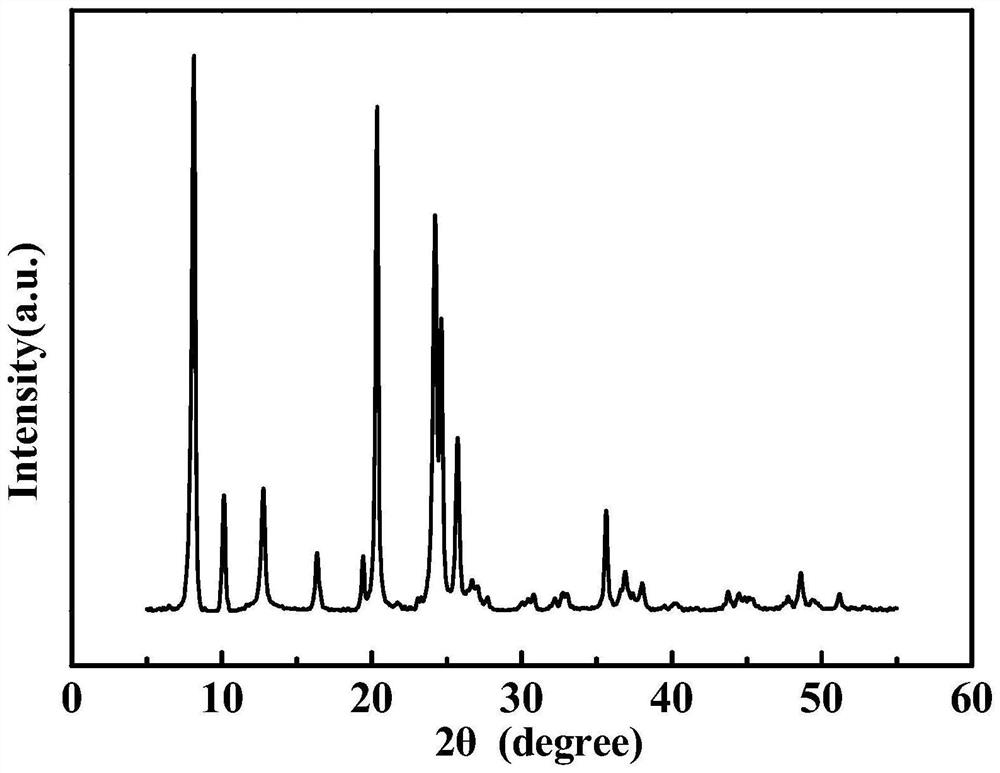

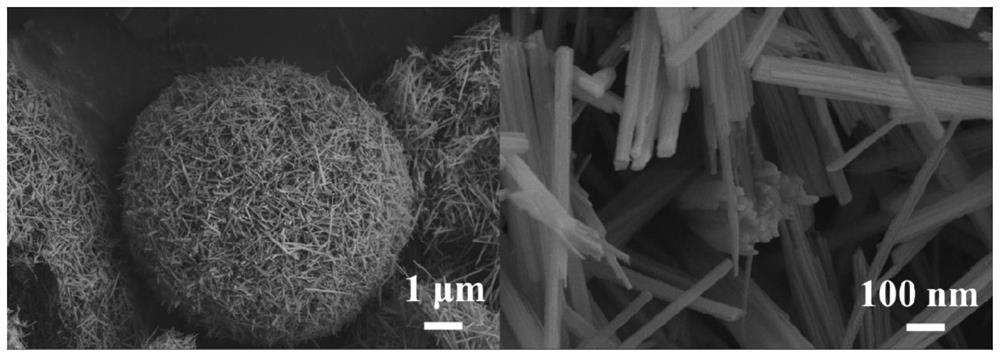

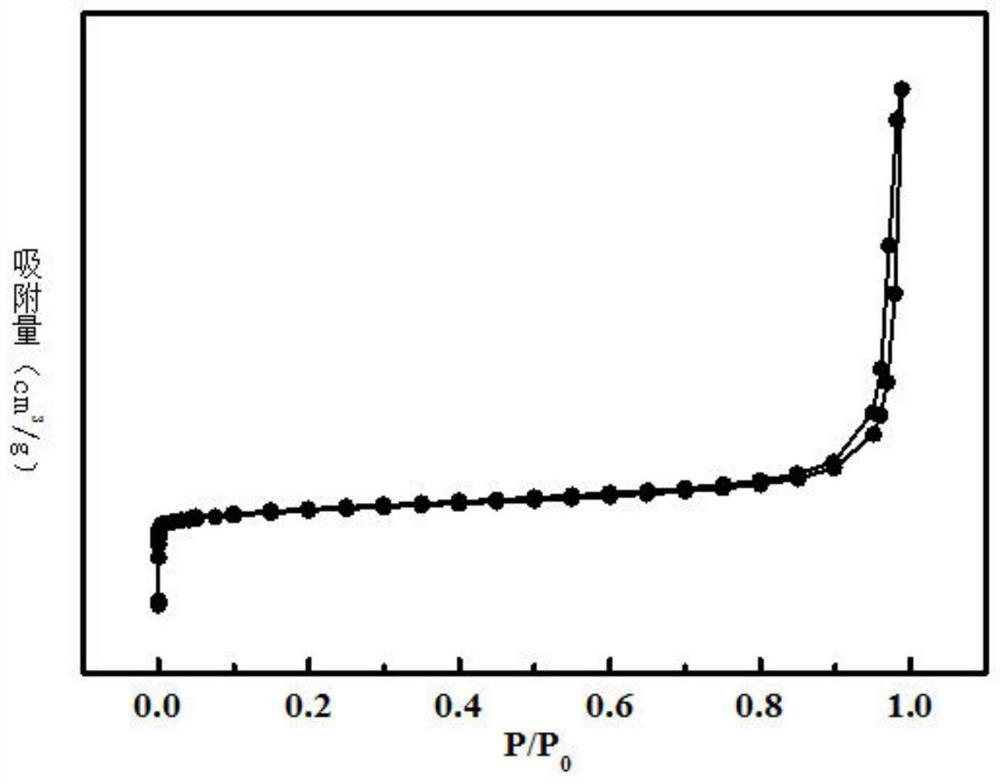

Method for synthesizing hierarchical pore ZSM-22 molecular sieve by adopting single template method

A multi-level pore, molecular sieve technology, applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of long one-dimensional micropore channels and large amount of organic template agent, and shorten the micropore channel. , the effect of improving the yield and shortening the diffusion distance of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific implementation mode one: the method for synthesizing the multi-level porous ZSM-22 molecular sieve by the single template method in this embodiment is realized according to the following steps:

[0031] 1. According to the molar ratio of 1: (0.005 ~ 0.02): (0.1 ~ 0.5): (0.002 ~ 0.01): (10 ~ 50) silicon source, aluminum source, alkali source, PHMB templating agent (polyhexamethylene Biguanide) and water are fully mixed to obtain the initial gel mixture;

[0032] 2. Crystallization: The initial gel mixture is placed in a closed stainless steel reaction kettle with a polytetrafluoroethylene liner, and the crystallization reaction is carried out at a crystallization temperature of 140-190°C for 1-3 days, and then cooled to room temperature, and then successively undergo centrifugation, washing and drying, put it into a muffle furnace, and roast it at a temperature of 500-600°C to obtain a multi-stage porous ZSM-22 molecular sieve.

[0033] Step 1 of this embodimen...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the silicon source described in step 1 is silica sol.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is different from Embodiment 2 in that the mass fraction of the silica sol is 20.0-40.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com