A catalyst for preparing 1-hexene by disproportionation and oligomerization of butene, its preparation method and application

A catalyst and hexene technology, applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of complex product components, low target conversion rate, poor comprehensive benefit, etc., achieve high yield and improve selectivity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

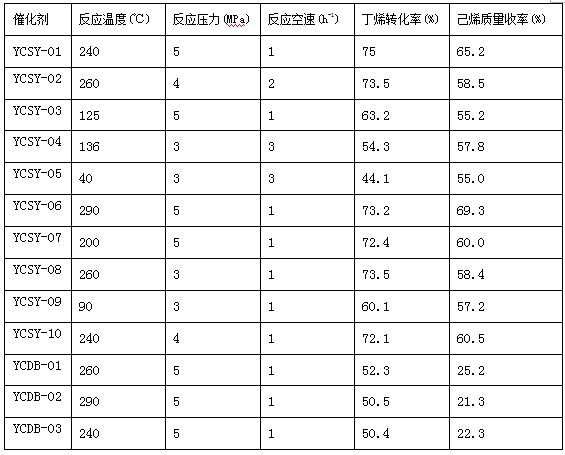

Examples

Embodiment 1

[0025] A catalyst for the preparation of 1-hexene by disproportionation and oligomerization of butene, containing 5g of tungsten oxide, 3g of molybdenum oxide, 1g of nickel oxide, 3g of cobalt-tungsten compound salt, and 88g of carrier ZSM-5 molecular sieve, wherein the cobalt Tungsten compound salt is composed of cobalt L-phenylalanine and tungsten L-homomalate in a weight ratio of 1:4. The catalyst number is YCSY-01.

[0026] The preparation method of the catalyst: Soak the carrier in 1mol / L sodium hydroxide solution for 4 hours to activate it, take it out, soak it in the salt solution made of sodium metatungstate, ammonium molybdate and nickel hydroxide, and ultrasonicate it at a frequency of 100MHz Disperse for 4 hours, then take it out, bake it at 550°C for 6 hours, cool it down to room temperature naturally, soak it in the salt solution with cobalt-tungsten compound salt for 4 hours, take it out and dry it at 105°C for 6 hours.

Embodiment 2

[0028] A catalyst for the preparation of 1-hexene by disproportionation and oligomerization of butene, containing 3g of tungsten oxide, 1g of molybdenum oxide, 5g of cobalt-tungsten compound salt, and 91g of carrier ZSM-5 molecular sieve, wherein the cobalt-tungsten compound salt It is composed of cobalt L-phenylalanine and tungsten L-homomalate in a weight ratio of 1:2. The catalyst number is YCSY-02.

[0029] The preparation method of the catalyst: Soak the carrier in 1mol / L sodium hydroxide solution for 5 hours to activate it, take it out, soak it in the salt solution made of sodium metatungstate, ammonium molybdate and nickel hydroxide, and ultrasonicate it at a frequency of 300MHz Disperse for 6 hours, then take it out, bake it at 550°C for 6 hours, cool it down to room temperature naturally, soak it in the salt solution with cobalt-tungsten compound salt for 6 hours, take it out and dry it at 105°C for 8 hours.

Embodiment 3

[0031] A catalyst for the preparation of 1-hexene by disproportionation and oligomerization of butene, containing 5g of tungsten oxide, 2g of molybdenum oxide, 1g of nickel oxide, 10g of cobalt-tungsten compound salt, and 82g of carrier ZSM-5 molecular sieve, wherein the cobalt Tungsten compound salt is composed of cobalt L-phenylalanine and tungsten L-homomalate in a weight ratio of 1:4. The catalyst number is YCSY-03.

[0032] The preparation method of the catalyst: Soak the carrier in 1mol / L sodium hydroxide solution for 6h to activate it, take it out, soak it in the salt solution made of sodium metatungstate, ammonium molybdate and nickel hydroxide, and ultrasonicate it at a frequency of 500MHz Disperse for 5 hours, then take it out, bake it at 550°C for 5 hours, cool it down to room temperature naturally, soak it in the salt solution with cobalt-tungsten compound salt for 5 hours, take it out and dry it at 105°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com