Complex method for improving efficiency of chalcopyrite leaching conducted through sulfur oxidation cultures

A technology of sulfur-oxidizing bacteria and chalcopyrite, applied in the biological field, can solve problems such as low utilization efficiency, low cell culture efficiency, and slow growth rate of chemoautotrophic bacteria, so as to improve leaching efficiency, increase cell concentration, and reduce Effects of blunting threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 High-density cultivation of Thiobacillus thiooxidans and cell collection without sulfur slag and slag

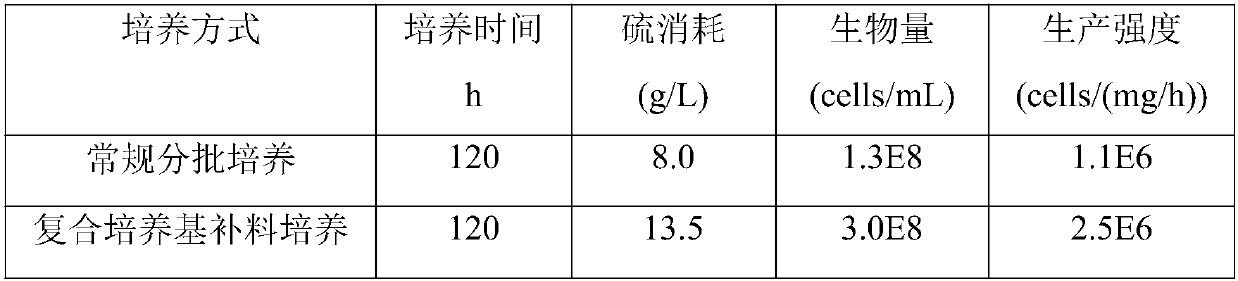

[0022] Starkey complex medium consists of three parts, the first part contains (NH 4 ) 2 SO 4 0.3g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 0.5g, CaCl 2 0.25g, Fe 2 (SO 4 ) 3 ·7H 2 O 0.018g, H 2 O 1000 mL; the second part: elemental sulfur 5g / L; the third part 0.5% (w / v) chalcopyrite-deficient; the first and second parts are sterilized and mixed to adjust the pH to 2.0. The ore samples were taken from the Tonglingshan mining area in Anhui Province. After preliminary crushing and filtration with steel sieves, the ore particle size is about <48μm. The first part is sterilized at 121°C for 20 minutes by autoclaving. Then the two parts were mixed and shaken, and the pH of the solution was adjusted to 2.0 with 2 mol / L hydrochloric acid. Thiobacillus thiooxidans ZJJN was inoculated into Starkey complex basal medium for culture. When the reduced sulfur in ...

Embodiment 2

[0026] Example 2 Appropriate supplementation of iron ions and elemental sulfur in the early stage of leaching shortens the lag period

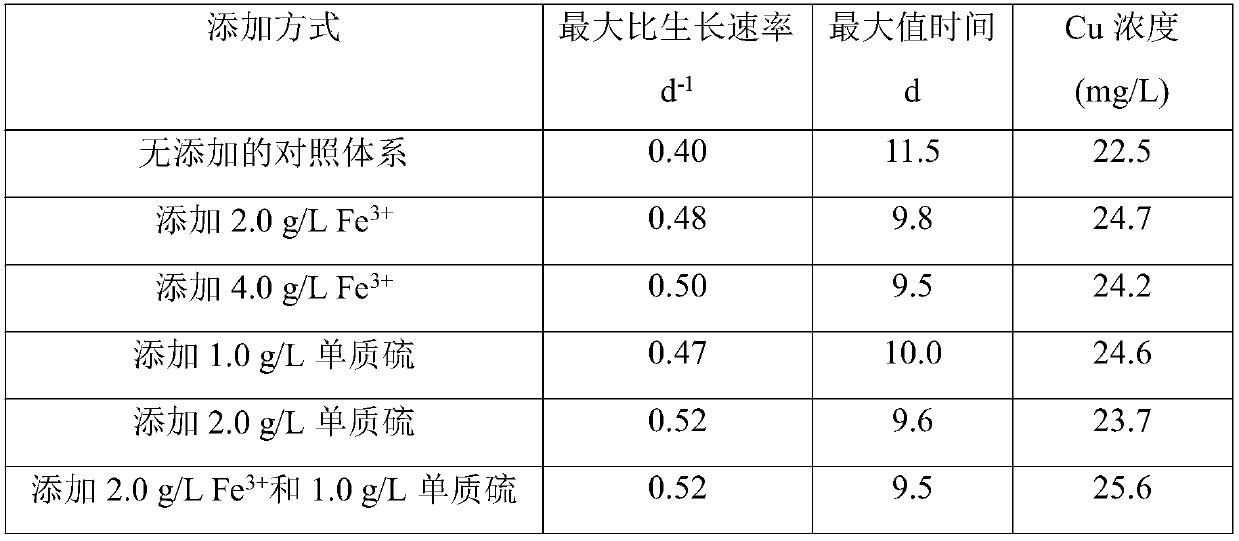

[0027] The chalcopyrite compound culture medium adopts Starkey basal medium (formula (NH 4 ) 2 SO 4 0.3g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 0.5g, CaCl 2 0.25g, Fe 2 (SO 4 ) 3 ·7H 2 O 0.018g, H 2 (2 1000mL), the control chalcopyrite slurry concentration is 2.0%; 30 ℃ of temperature, shaker speed 170rpm, control initial cell by inoculation about 5.0 * 10 7 individual / mL. Add 2.0g / L iron ion and 2.0g / L elemental sulfur during the inoculation process of the leaching system (the inoculum size is 5.0×10 7 / mL), the key parameters and leaching results of the bacterial growth in the leaching process are shown in Table 2. Maximum specific growth rate changed from 0.40d -1 Improve to 0.52d -1 , and the time required to reach the maximum specific growth rate is reduced from 11.5d to 9.5d. Add 2.0g / L Fe 3+and 1.0g / L elemental sulfur obta...

Embodiment 3

[0030] Example 3 Constant pH Coupled Pulse Supplementation of Sulfur Oxidizing Bacteria Cells to Enhance Iron / Sulphur Metabolism in the Late Stage of Leaching

[0031] Since the introduction of some iron ions in the early stage enhances iron metabolism, jarosite will be produced in the later stage, covering the mineral surface and making leaching impossible, which is the key factor for the low bioleaching rate of chalcopyrite. 15d begins after leaching begins (adding 2.0g / LFe of other steps and embodiment 2 3+ Consistent with the 1.0g / L elemental sulfur system), 6mol / L hydrochloric acid is used to adjust the pH of the leachate to 1.0 every day to maintain a relatively stable acidic environment and reduce the generation of jarosite. At the same time, add 5.0×10 every three days 7 Each / mL Thiobacillus thiooxidans cells can continuously strengthen the biological effect of the leaching process, and the hydrogen ions produced while enhancing sulfur metabolism can also resist the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com