Automatic fixed-length cutting equipment for stainless steel-teflon braided tube

A polytetrafluoroethylene, automatic length-fixing technology, which is applied in metal processing and other directions, can solve the problems of affecting operation and processing efficiency, short service life of saw blades, and affecting production efficiency, so as to improve fusing efficiency, high cutting precision, and cutting efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

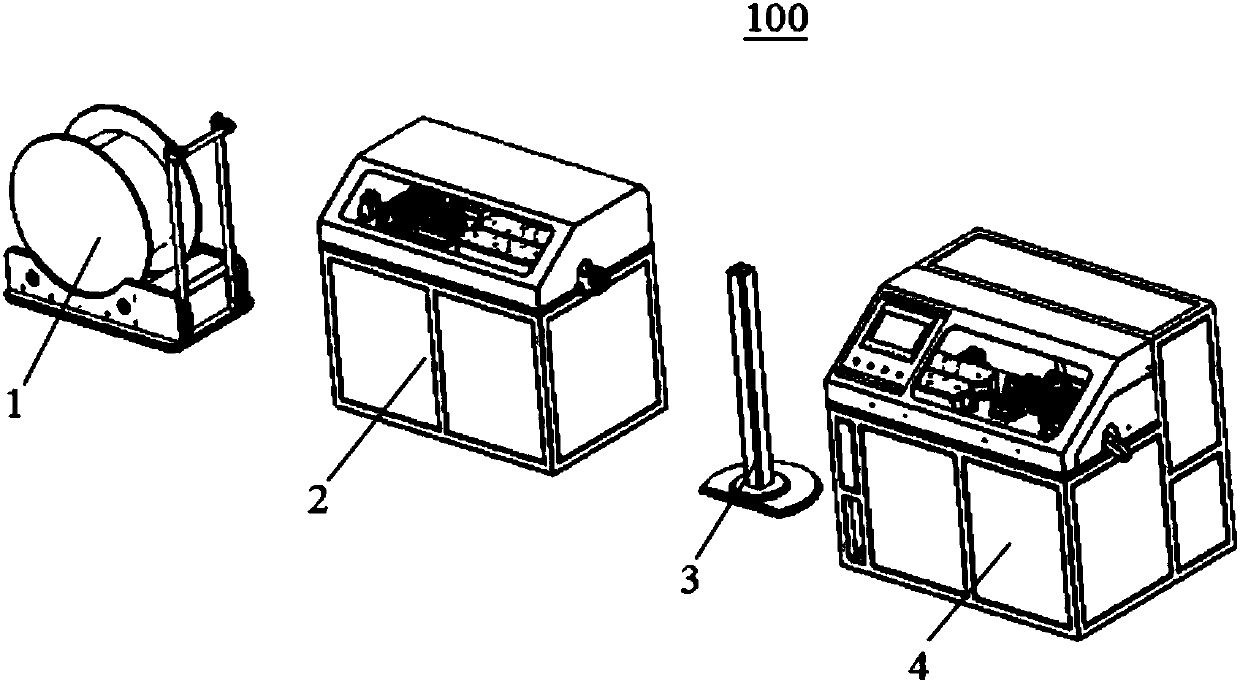

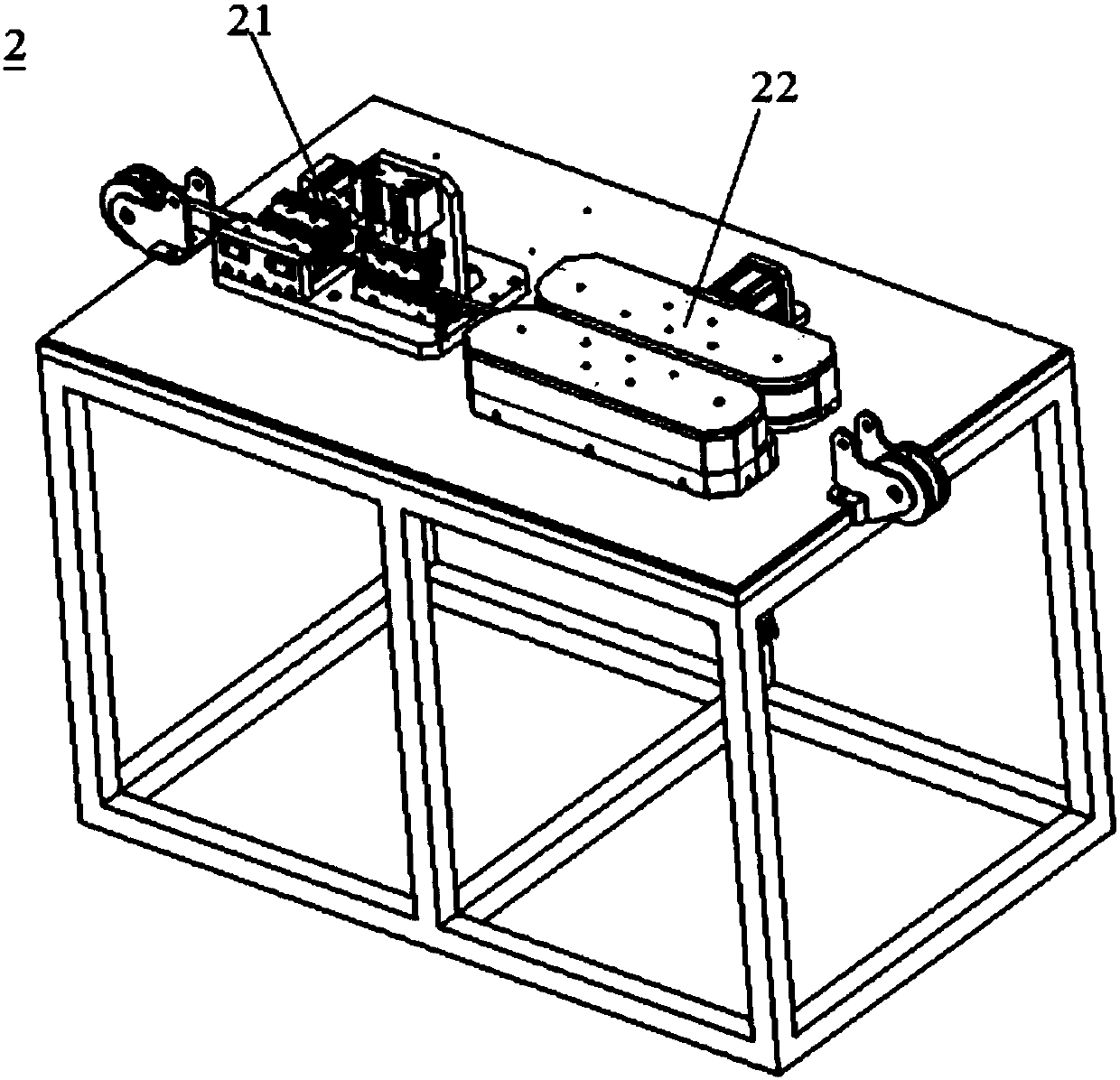

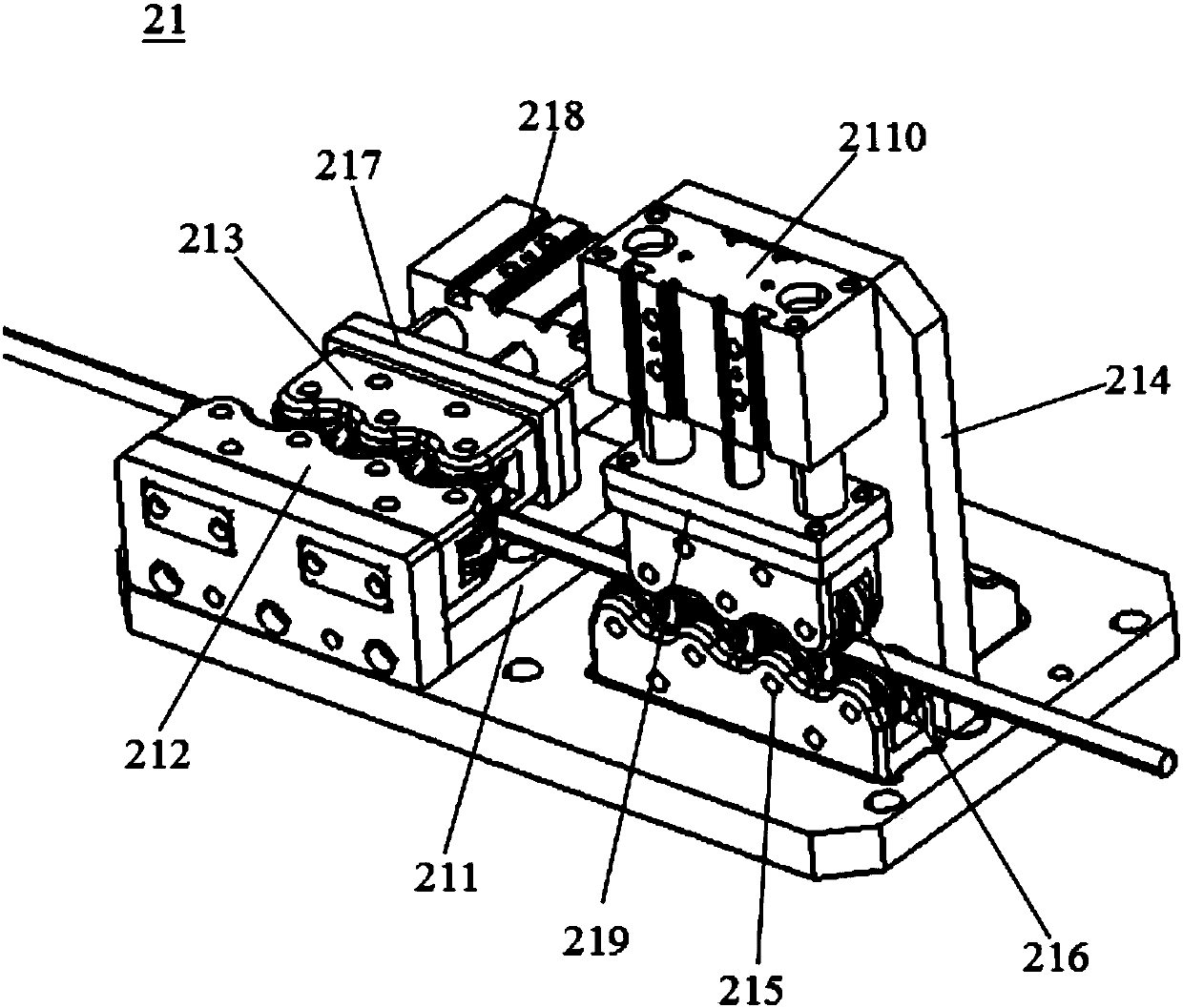

[0026] Please refer to Figure 1-Figure 6 , the present embodiment is an automatic fixed-length cutting equipment 100 for stainless steel polytetrafluoroethylene braided pipe, which includes a feeding mechanism 1 , a traction straightening mechanism 2 , a counterweight storage mechanism 3 and a melting and cutting mechanism 4 .

[0027] The feed feeding mechanism 1 can adopt a horizontal rotating disk or a bearing frame. Place the roll-shaped pipe reel on the horizontal rotating disk. When one end of the pipe is pulled forward, the pipe reel rotates with the horizontal rotating disk to realize discharging. Or set the roll-shaped pipe reel on the bearing frame through the pin shaft. When one end of the pipe is pulled forward, the pipe reel rotates vertically to realize discharging. A servo motor may also be provided at the lower end of the horizontal rotating disk to drive the horizontal rotating disk to rotate and automatically feed. Similarly, the above-mentioned pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com