Spinning bottom coating metal stone inner container pot manufacturing technology and cooker manufactured through same

A production process and stone technology, which is applied to the production process of spinning bottom-covered metal stone liner pots and the field of pots and utensils prepared and prepared, and can solve the problems of inability to cover the bottom with metal sheets and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

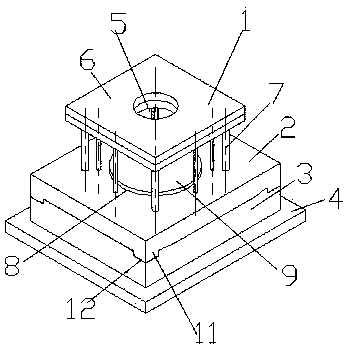

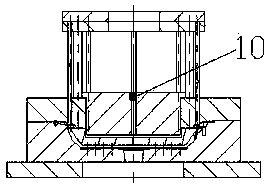

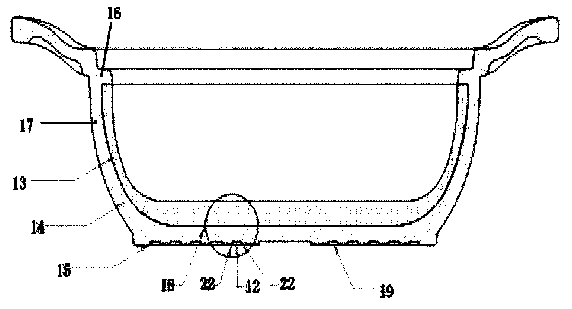

[0048] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0049] A manufacturing process of a spinning bottom-covered metal stone inner pot, comprising the following steps:

[0050] Step 1—Making of rough stone liner:

[0051] (3) Material selection: stone varieties are granite, chicken claw stone granite, medical stone, black amphibole, volcanic rock, amphibole granite, biotite granite, talc granite, electric granite, etc., using water jet machine water cutting or circular sawing machine Large stone blocks cut into square cubes or cylindrical shaped cubes.

[0052] (4) Secondary cutting: Cut the stone into secondary products, each of which weighs 0.1 to 7 tons and has a volume of 0.1 to 2 cubic meters. The size is 2 meters long, 1 meter wide and 1 meter high, and then The surface is smoothed by a stone surface planer, and the quality inspection requirements: the obtained stone needs to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com