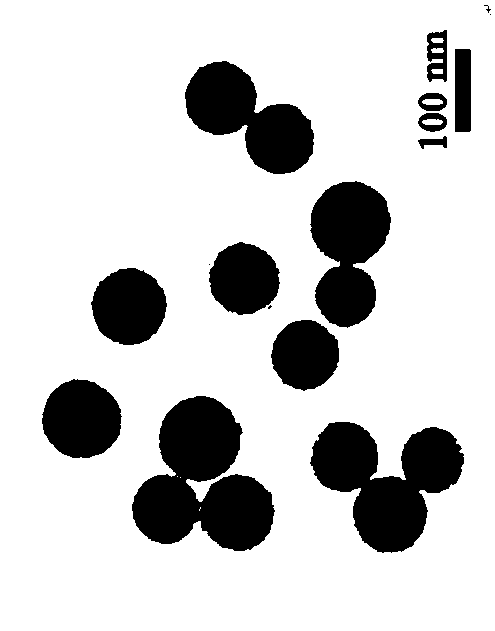

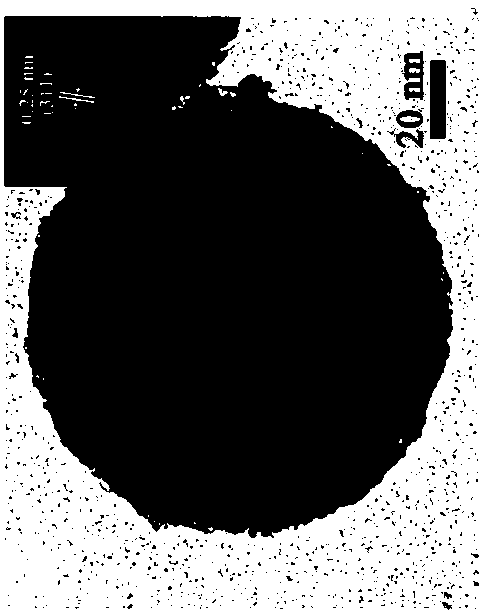

Pomegranate-shaped Fe3O4@N-C lithium battery cathode material preparation method thereof

A pomegranate-shaped, lithium battery technology, applied in nanocomposite materials and their application fields, can solve the problems of poor stability of ultra-small particles, restricting development, and difficult to large-scale synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Fe 3 o 4 Preparation of @N-C nanoparticle anode material

[0022] Add 40 mg of polyacrylic acid, 100 μL of ammonia water and 20 mL of deionized water into a 100 mL round-bottomed flask in turn, stir and mix evenly, slowly add 80 mL of isopropanol into the solution dropwise, and then add 50 mg ferrous chloride tetrahydrate, stirred at room temperature for 3 h. The above solution was centrifuged, and the precipitate was at 50 o C oven for 8 h. Subsequently, the solid was placed in a tube furnace under the protection of argon for 500 o C calcined for 5 h to obtain pomegranate-like Fe 3 o 4 @N-C high-performance lithium battery anode material.

Embodiment 2

[0023] Example 2 Fe 3 o 4 Preparation of @N-C high-performance lithium battery anode materials

[0024] Add 50 mg of polyacrylic acid, 130 μL of ammonia water and 23 mL of deionized water into a 100 mL round-bottomed flask in turn, stir and mix evenly, slowly add 100 mL of isopropanol into the solution dropwise, and then add 60 mg ferrous chloride tetrahydrate, stirred at room temperature for 4 h. The above solution was centrifuged, and the precipitate was at 50 o C oven for 10 h. Subsequently, the solid was placed in a tube furnace under the protection of argon for 600 o C was calcined for 10 h to obtain pomegranate-like Fe 3 o 4 @N-C high-performance lithium battery anode material.

Embodiment 3

[0025] Example 3 Fe 3 o 4 Preparation of @N-C nanoparticle anode material

[0026] Add 43 mg of polyacrylic acid, 150 μL of ammonia water and 30 mL of deionized water into a 100 mL round-bottomed flask in sequence, stir and mix evenly, slowly add 100 mL of isopropanol into the solution dropwise, and then add 100 mg ferrous chloride tetrahydrate, stirred at room temperature for 5 h. The above solution was centrifuged, and the precipitate was at 50 o C oven for 10 h. Subsequently, the solid was placed in a tube furnace under the protection of argon at 550 o C calcined for 8 h to obtain pomegranate-like Fe 3 o 4 @N-C high-performance lithium battery anode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com