Spherical rhenium powder preparation method

A rhenium powder and spherical technology, applied in the field of spherical rhenium powder preparation, can solve the problems of low adsorption performance of small particle powder, small particle size of spherical powder, difficult application in 3D printing field, etc., and achieves reduction of fine powder loss and good powder densification performance. , the effect of low content of hollow spheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

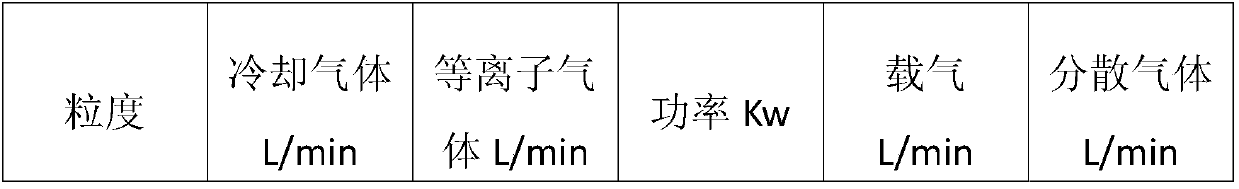

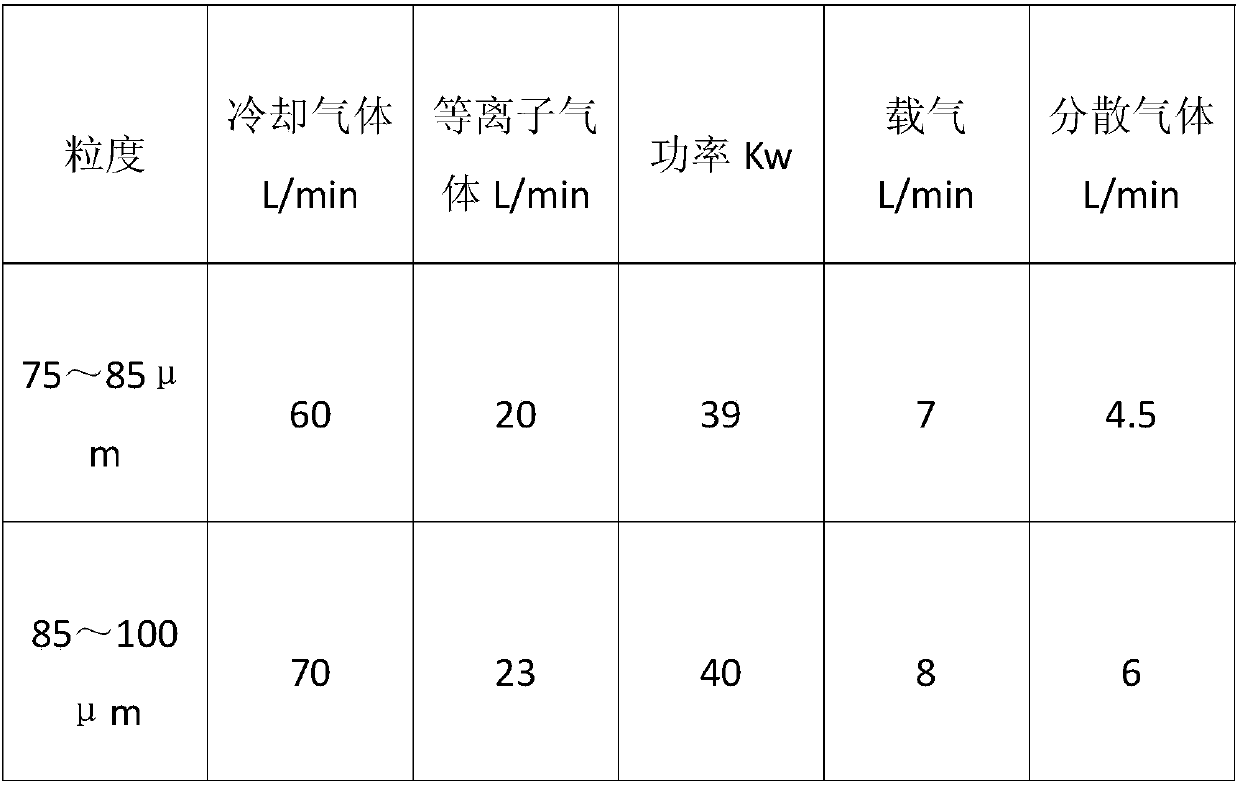

[0027] Example 1 Preparation of spherical rhenium powder with particle size ranging from 0 to 45 μm

[0028] Weigh 1.5kg of high-purity ammonium rhenate raw material, roast ammonium rhenate at 280°C for 1h, the roasting atmosphere is hydrogen, and the flow rate is controlled at 3L / min;

[0029] After cooling, crush, grind, and pass through a 500-mesh sieve to obtain rhenium oxide powder with a particle size of less than 25 μm;

[0030] For mixing, put rhenium oxide powder, 500ml of alcohol, and 150g of ammonium rhenate into a vacuum mixing tank, vacuumize to -0.08Mpa, mix for 4 hours, and pump air every 2 hours to discharge the gas in the rhenium oxide particles. Let the ammonium rhenate solution enter the pores for filling;

[0031] After taking it out, heat and dry it in a water bath, crush it, and put it into a molybdenum boat;

[0032] Put it into a molybdenum wire furnace with hydrogen atmosphere at room temperature for two-stage reduction, 280°C for 1h in hydrogen atmo...

Embodiment 2

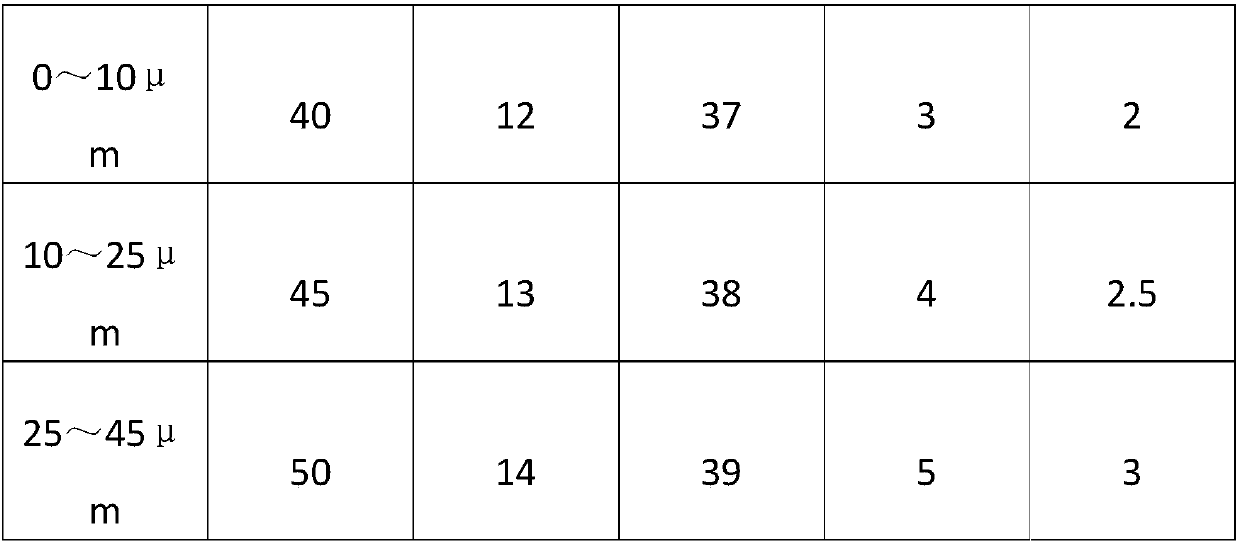

[0043] Example 2 Preparation of spherical rhenium powder with particle size ranging from 75 to 100 μm

[0044] Weigh 1.5kg of high-purity ammonium rhenate raw material, roast ammonium rhenate at 280°C for 1h, the roasting atmosphere is hydrogen, and the flow rate is controlled at 3L / min.

[0045] After cooling, crush, grind, and pass through a 200-mesh sieve to obtain rhenium oxide powder with a particle size of less than 74 μm.

[0046] For mixing, put rhenium oxide powder, 500ml of alcohol, and 150g of ammonium rhenate into a vacuum mixing tank, vacuumize to -0.08Mpa, mix for 4 hours, and pump air every 2 hours.

[0047] After taking it out, heat and dry it in a water bath and crush it.

[0048] Put it into a molybdenum wire furnace with hydrogen atmosphere at room temperature for two-stage reduction, 280°C for 1 hour (flow rate 4L / min), and 900°C for 2 hours, both in hydrogen atmosphere (flow rate 8L / min).

[0049] After taking out, crush, grind, and pass through a 180-mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com