Reaction kettle for enhanced exothermic reaction

A technology of exothermic reaction and reaction kettle, applied in the field of reaction kettle, strong exothermic system including gas-liquid mass transfer and reaction, can solve the problems of poor mass transfer and heat transfer capacity, untimely heat, poor safety and so on , to achieve the effect of fast gas-liquid mass transfer rate, timely removal of heat, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

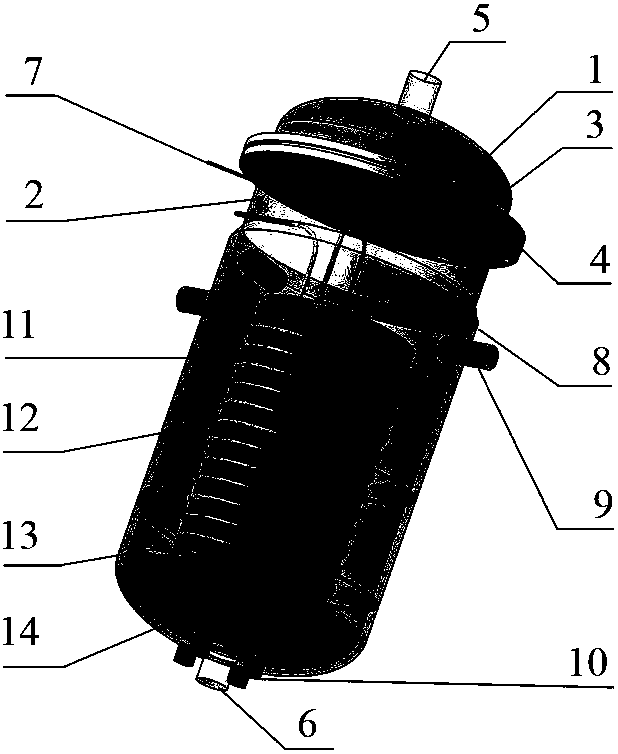

[0023] A reactor for strongly exothermic reactions, which can be used in the synthesis process of phosphorus oxychloride.

[0024] The raw material phosphorus trichloride is transported by the pump through the phosphorus trichloride storage tank to the liquid-phase raw material feed port 5 at the top of the reactor, and then enters the reactor. Oxygen enters the liquid oxygen evaporator from the liquid oxygen storage tank to become gaseous oxygen, and the oxygen enters the gas distributor 14 through the gas-phase raw material inlet 7 at the top of the reactor and becomes small bubbles dispersed in the phosphorus trichloride liquid. The installation position of the gas distributor 14 is flush with the bottom of the draft tube 11 to ensure that the bubbles have a long enough movement path in the reactor. Wherein, the diameter of guide cylinder 11 is 0.95 times of the diameter of lower kettle body 2, and its bottom is flush with the bottom of the straight section of lower kettle ...

Embodiment 2

[0026] A reactor for highly exothermic reactions, which can be used in the acetic acid synthesis process.

[0027] The raw material acetaldehyde is transported by the pump through the acetaldehyde storage tank to the liquid-phase raw material inlet 5 at the top of the reactor, and then enters the reactor. Oxygen enters the liquid oxygen evaporator from the liquid oxygen storage tank to become gaseous oxygen, and the oxygen enters the gas distributor 14 through the gas phase raw material inlet 7 at the top of the reactor and becomes small bubbles dispersed in the acetaldehyde liquid. The installation position of the gas distributor 14 is in the guide tube 11 and is flush with the bottom thereof, so as to ensure that the bubbles have a long enough movement path in the reactor. Wherein, the diameter of diversion cylinder 11 is 0.7 times of lower kettle body 2 diameters, and its bottom and lower kettle body 2 straight section bottoms differ by 10 cm, and its height is lower than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com