Iron oxyhydroxide nanorod/foam carbon composite material and preparation method and application thereof

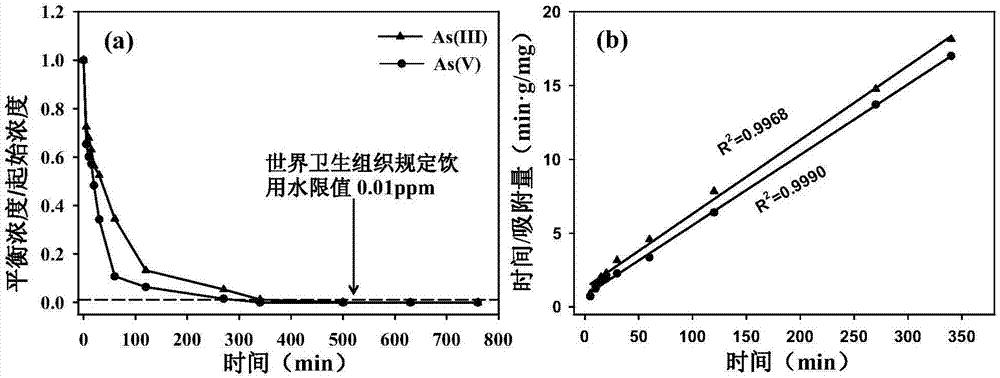

A technology of iron oxyhydroxide and composite materials, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of low efficiency, small adsorption capacity, difficult separation and recovery, etc., and achieve easy separation, recovery, adsorption, etc. The effect of strong ability and fast mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

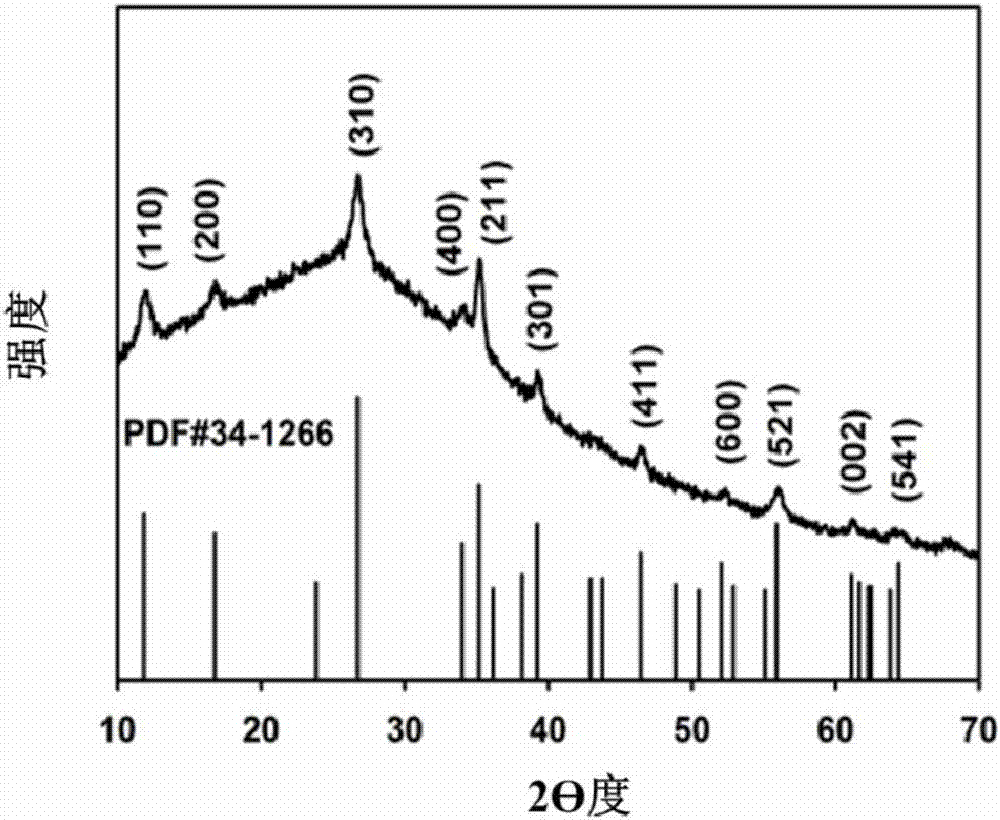

[0033] An iron oxyhydroxide nanorod / carbon foam composite material prepared by the following steps:

[0034] Step a: Mix 120 μL of a hydrochloric acid solution with a solute mass fraction of 37.5%, 11.88 mL of deionized water, and 28 mL of acetonitrile to prepare a first reaction solution.

[0035] Step b. Heat the foam at a heating rate of 5°C per minute until the temperature reaches 700°C, keep it for 2 hours, and then put it into a nitric acid solution with a concentration of 3.5mol / L and cook at 120°C for 2 hours. Get acidified foam charcoal.

[0036] Step c, add 0.0135mol FeCl 3 And 0.04mol NaNO 3 Dissolve in 40ml of the first reaction solution prepared in step a, add the acidified foamed charcoal prepared in step b after stirring for 30 minutes, continue stirring for 1 hour, and then transfer it to a 50ml reactor at 100°C The hydrothermal reaction was performed for 4 hours, and then washed with deionized water several times, and then placed in a drying box for drying at a dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com