Co-Al-W based high-temperature alloy based on cluster and linking atom model

A high-temperature alloy and atomic technology, which is applied in the field of high-temperature alloys, can solve the problems of narrow two-phase regions, insufficient, and γ′-phase unstable alloy high-temperature strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

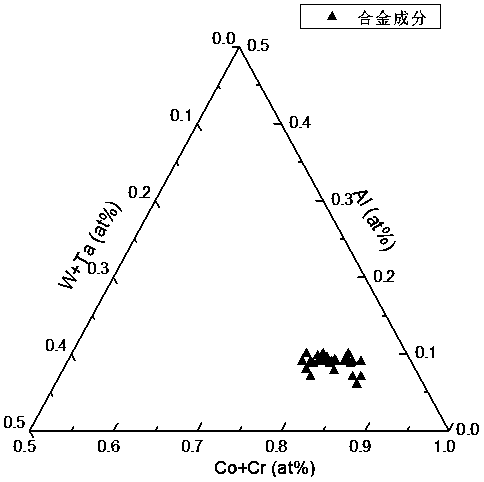

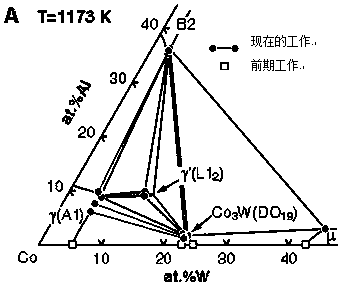

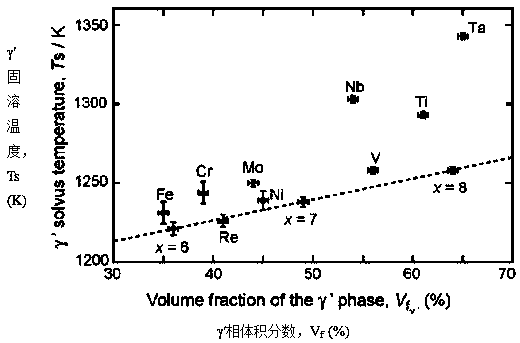

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Co 80.92 Al 9 W 8 Ta 2 B 0.08 alloy:

[0020] 1. Alloy preparation: change the elements from atomic percentage to mass percentage for proportioning; use a non-consumable vacuum melting furnace to melt the prepared alloy raw materials several times under the protection of Ar gas atmosphere to achieve the purpose of uniform composition, and finally get alloy ingot. After the ingot is obtained, the measured actual composition is compared with the nominal composition, and the experimental error is controlled within the designed range.

[0021] 2. Observation of the as-cast structure: metallographic preparation of the as-cast sample is carried out, and the structure of the sample is observed with a metallographic microscope.

[0022] 3. Use DSC to measure the transformation point of the alloy, and set the heating / cooling rate to 5 K / min. The solidus temperature of the alloy is 1687K, the liquidus temperature is 1712K and the solid solution temperature of the...

Embodiment 2

[0028] Example 2 Co 81.5 Al 9.5 W 6 Ta 3 Cr 3 Coideal1 alloy

[0029] 1. Alloy preparation: change the elements from atomic percentage to mass percentage for proportioning; use a non-consumable vacuum melting furnace to melt the prepared alloy raw materials several times under the protection of Ar gas atmosphere to achieve the purpose of uniform composition, and finally get alloy ingot. After the ingot is obtained, the measured actual composition is compared with the nominal composition, and the experimental error is controlled within the designed range.

[0030] 2. Observation of the as-cast structure: metallographic preparation of the as-cast sample is carried out, and the structure of the sample is observed with a metallographic microscope.

[0031]3. Use DSC to measure the transformation point of the alloy, and set the heating / cooling rate to 5 K / min.

[0032] 4. Formulate a heat treatment system, including solution treatment temperature and duration, and aging temp...

Embodiment 3

[0033] Example 3 Co 69.5 Ni 9 Al 9.5 W 6 Ta 3 Cr 6 Coideal1 alloy

[0034] 1. Alloy preparation: change the elements from atomic percentage to mass percentage for proportioning; use a non-consumable vacuum melting furnace to melt the prepared alloy raw materials several times under the protection of Ar gas atmosphere to achieve the purpose of uniform composition, and finally get Alloy ingots. After the ingot is obtained, the measured actual composition is compared with the nominal composition, and the experimental error is controlled within the designed range.

[0035] 2. Observation of the as-cast structure: metallographic preparation of the as-cast sample is carried out, and the structure of the sample is observed with a metallographic microscope.

[0036] 3. Use DSC to measure the transformation point of the alloy, and set the heating / cooling rate to 5 K / min.

[0037] 4. Formulate a heat treatment system, including solution treatment temperature and duration, and ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com