Metal-imitated coating for building external walls and preparation method of metal-imitated coating

A technology for building exterior walls and imitating metal, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as environmental pollution, poor dispersion stability of water-based flash paint against strong mechanical forces, and impact on weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

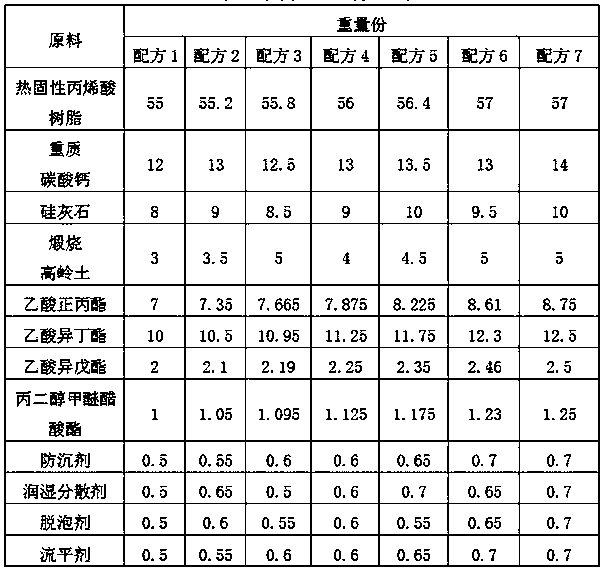

[0103] Embodiment 1 primer A and primer supporting construction B raw material matching

[0104] The formula of primer A and primer matching agent B is as follows:

[0105] Table 3: Raw material matching table for primer A

[0106]

[0107] Thinner is the mixture of ester in table 3, is the mixture of n-propyl acetate, isobutyl acetate, isoamyl acetate, propylene glycol methyl ether acetate; Anti-settling agent is polyhydroxy carboxylic acid amide solution, modified urea solution and Any one or any mixture of several kinds of fumed silica; the wetting and dispersing agent is a low molecular weight unsaturated polycarboxylic acid polymer solution, a hydroxyl functional carboxylate solution containing a pigment affinity group, an acidic group containing Any one or any mixture of several of the alkylhydroxyl ammonium salt of the block copolymer, the neutral salt of the acidic polyester unsaturated polyamide and the modified acrylate block copolymer; the defoaming agent does n...

Embodiment 2

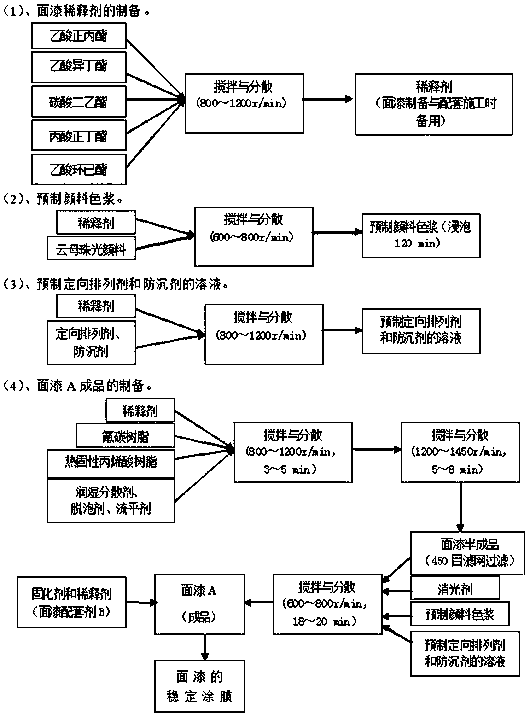

[0111] Embodiment 2 topcoat A and topcoat supporting agent B raw material formula

[0112] Table 5: Raw material matching table for topcoat A

[0113]

[0114] Diluent is the mixture of ester in table 5, is the mixture of n-propyl acetate, isobutyl acetate, diethyl carbonate, n-butyl propionate, cyclohexyl acetate; Orientation arrangement to mica pearlescent pigment in alignment agent The additives are silicone resin additives containing silanol functional groups, wax dispersions of ethylene vinyl acetate and ethylene acrylic acid copolymer mixtures, ethylene vinyl acetate copolymer wax dispersions, low molecular weight unsaturated acidic polycarboxylic acid polyesters with polysilicon Any one or any mixture of several of the oxane copolymer solution and the aromatic-free polyethylene wax dispersion; the alignment agent for the matting agent is aralkyl-modified polymethylalkylsiloxane , carboxyl-containing copolymer modified liquid and silicone-containing high molecular we...

Embodiment 3

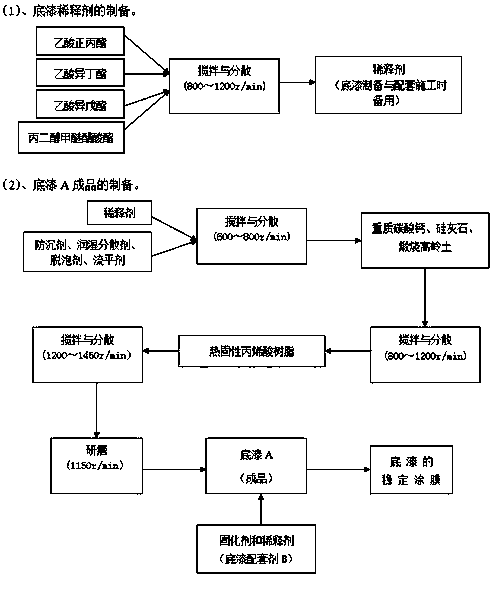

[0118] Embodiment 3 The preparation method 1 of building exterior wall imitation metal paint

[0119] (1) The preparation method of the primer, comprising the following steps:

[0120] ①Preparation of diluent: Pour the mixture of esters, 45 parts by weight, into the container barrel, and stir and disperse at the speed of 800-1200r / min with the mixer for 5-8 minutes; The diluent prepared by A finished product has 20 parts by weight; the diluent used for primer matching agent B construction has 25 parts by weight;

[0121] ②Preparation of finished primer A:

[0122] a take diluent, parts by weight are 20; anti-settling agent, parts by weight are 0.5; wetting and dispersing agent, parts by weight are 0.5; defoamer, parts by weight are 0.5; 0.5 Pour it into the container bucket, adjust the speed of the mixer to 600-800r / min for stirring and dispersing, and the time is 3-5 minutes;

[0123] b. Add the filler, 23 parts by weight, into the container barrel, and adjust the speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com