Self-supporting graphene nanosheet surface-modified copper-based composite material and its preparation method and application

A technology of graphene nanosheets and copper-based composite materials, applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problem of failure to effectively prevent direct contact, increase the porosity of composite materials, and weaken the strengthening effect of graphene etc. to achieve excellent self-lubricating properties, improve interfacial bonding strength, excellent mechanical properties and self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

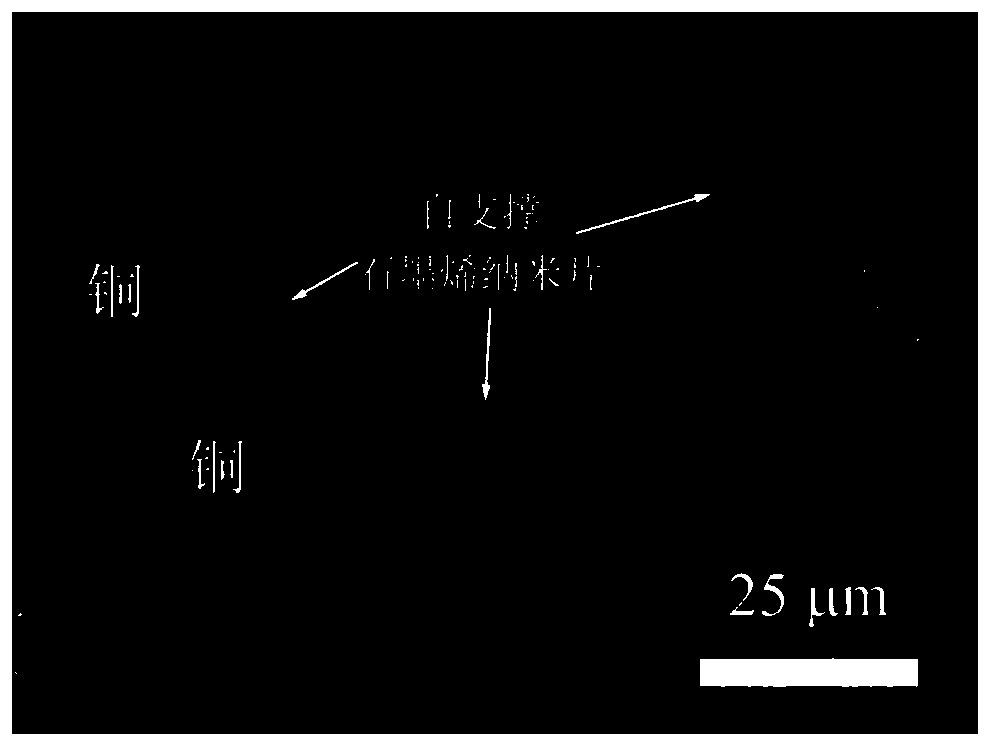

[0031] figure 1 It is a schematic diagram of the structure of a self-supporting graphene nanosheet surface-modified copper-based composite material. Among them, 1 is a graphene nanosheet, 2 is a copper matrix, 3 is a graphene / copper composite material, 4 is a self-supporting graphene nanosheet, and 5 is a self-supporting graphene nanosheet surface-modified copper-based composite material. The self-supporting graphene nanosheet surface-modified copper-based composite material 5 of the present invention is composed of graphene nanosheets 1 and a copper matrix 2. A part of the graphene nanosheets is uniformly dispersed inside the copper matrix to form a graphene / copper-based composite material 3. A part is uniformly dispersed on the surface of the material, and a part of the plane of these graphene nanosheets is embedded in the graphene / copper-based composite material, and a part is exposed on the surface of the graphene / copper-based composite material to form a self-supporting gra...

Embodiment 2

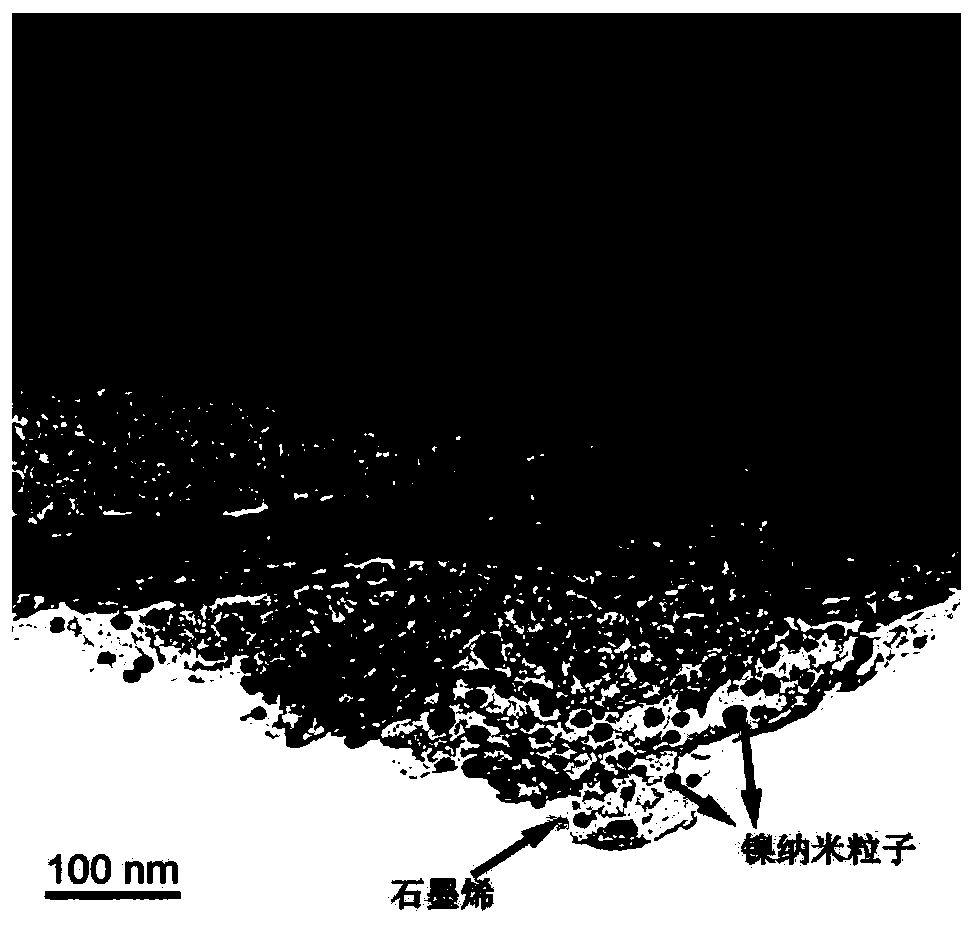

[0033] The graphene oxide powder (purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd.) was ultrasonically dispersed in deionized water to form 600ml of a dispersion with a concentration of 0.83mg / mL, and 15ml of diluted ammonia water with a concentration of 0.55mol / L was added, and after thorough stirring, Add 50ml of Ni(NO 3 ) 2 Aqueous solution. After reacting at room temperature for 1 hour, the product was filtered, rinsed with deionized water and dried, and then the dried product was reacted at 500° C. under an argon atmosphere for 1 hour to obtain nickel nanoparticle surface-modified graphene nanosheets.

[0034] figure 2 This is a TEM picture of the microstructure of the graphene nanosheets modified on the surface of the nickel nanoparticles obtained in this example. From figure 2 It can be seen that the size of the nickel nanoparticles is 10-20 nm, and they are uniformly pinned to the plane of the graphene nanosheet. Thermogravimetric analysis shows that ...

Embodiment 3

[0036] The difference from Example 2 is that the graphene oxide, ammonia and Ni(NO 3 ) 2 The concentration of the aqueous solution is 1mg / mL, 0.6mol / L, 30mmol / L, the reaction time at room temperature is 4 hours, the high temperature reaction temperature is 600℃, and the time is 2 hours, and the surface of nickel nanoparticles with a nickel mass fraction of 22.8% is obtained. Modified graphene nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com