System and method for treating calcium carbide residues

A technology of calcium carbide slag and water glass, applied in the direction of carbide, calcium carbide, etc., can solve the problems that calcium carbide slag cannot be recycled into calcium carbide, air-dried ash, pollutes the surrounding environment, etc., and achieves the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

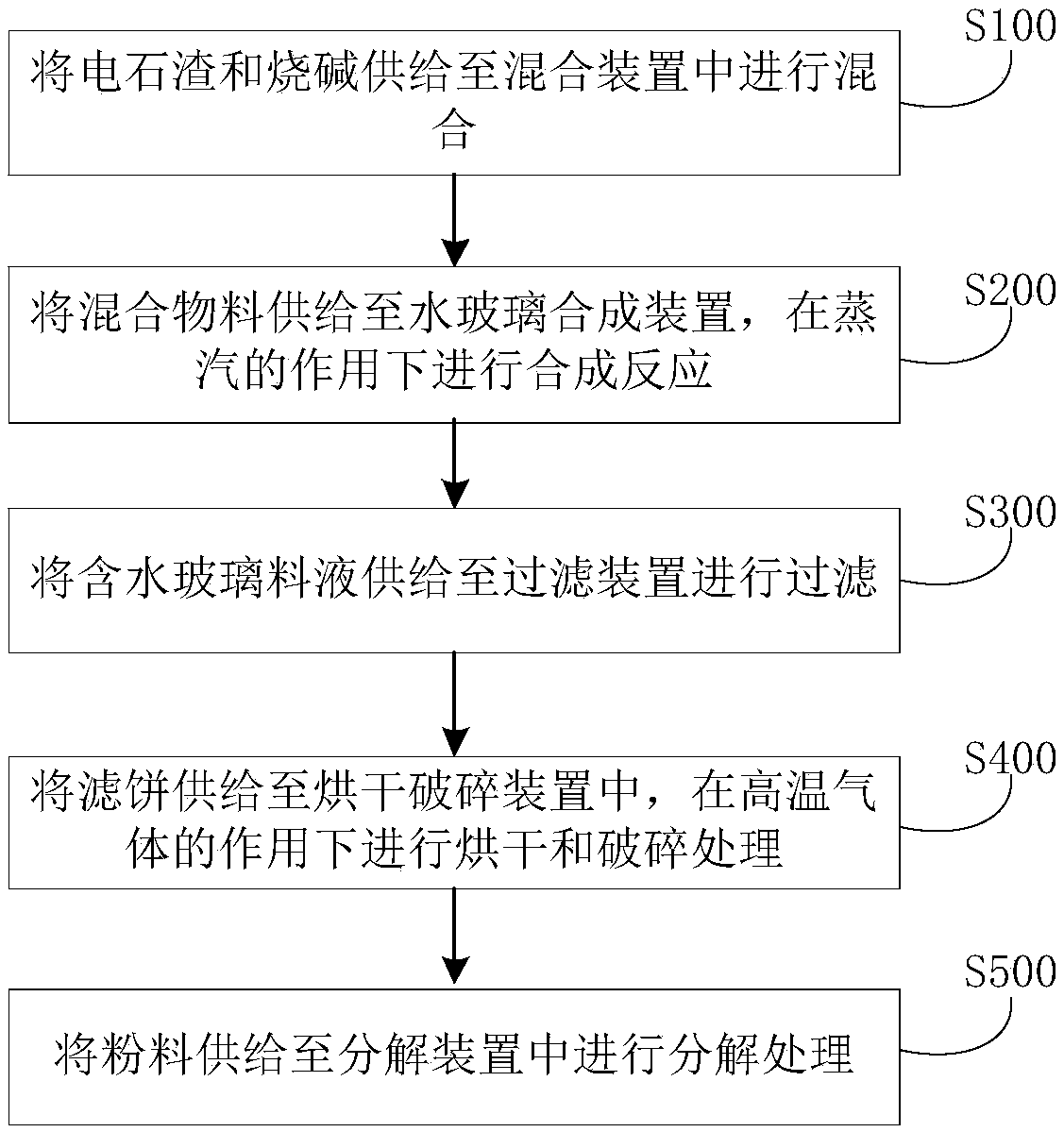

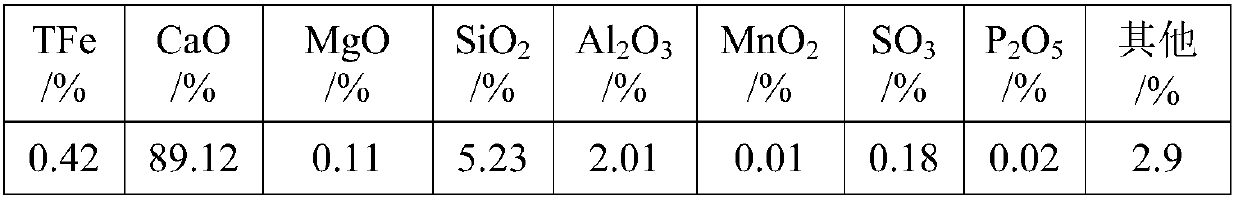

[0077] Carbide slag from a calcium carbide company in Inner Mongolia was used, and the composition is shown in Table 1.

[0078] Table 1 Composition analysis of calcium carbide slag after roasting

[0079]

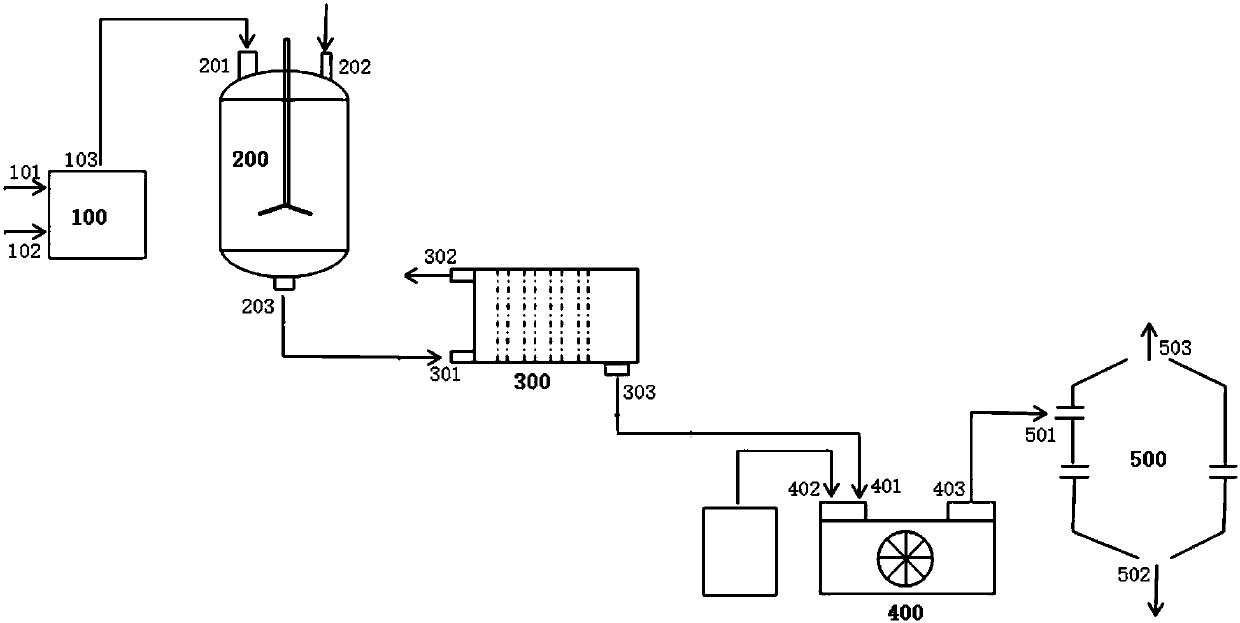

[0080] Mix calcium carbide slag and liquid caustic soda evenly, wherein calcium carbide slag (dry basis): liquid caustic soda (30wt%)=1000:70, after mixing evenly, pump the mixed material into the reaction kettle, and feed 0.7 to 0.8 MPa steam, directly heat the mixed material, and keep stirring to make it undergo a synthesis reaction. When the pressure of the reactor rises to 0.5-0.7 MPa and the temperature reaches 150-160 degrees Celsius, stop feeding the steam and keep the pressure and temperature stable for 4~ After 6 hours, open the outlet valve, send the water-containing glass feed liquid to the filter press of the filter device, filter through the plate filter press, and the filtrate enters the filtrate storage tank to obtain the crude water glass product, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com