Open-loop controllable high-precision rotation piezoelectric driving device and manufacturing method thereof

A manufacturing method and piezoelectric drive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of increasing the complexity of the control system, affecting the operation stability, Reduce the drive efficiency and life and other problems, to achieve the effect of improving the electromechanical energy conversion efficiency, improving the load balance, and improving the excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

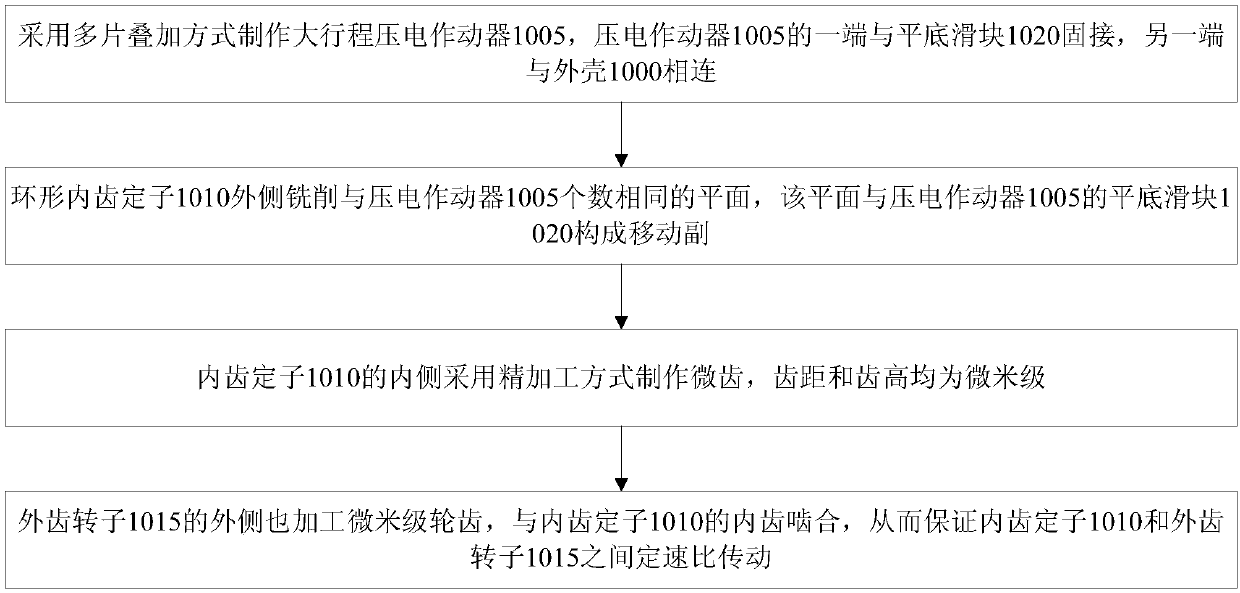

[0042] An embodiment of the present invention provides a piezoelectric drive device using a single stator assembly or multiple stator assemblies with micro-tooth meshing, including: several piezoelectric actuators, a stator with internal teeth and a rotor with external teeth.

[0043] Among them, the piezoelectric actuator works in the d33 mode, and adopts the lamination type to increase the amplitude-changing stroke. The piezoelectric actuators are installed radially and evenly distributed at equal intervals along the circumferential direction. One end of the piezoelectric actuator is fixedly connected to the casing by bolts, and the other end is movably connected to the outer side of the internal tooth stator through a moving pair.

[0044] Among them, micro-teeth are processed on the inner side of the inner-toothed stator, which mesh with micro-tooths on the surface of the external-toothed rotor. Under the action of the AC signal, each piezoelectric actuator produces an as...

Embodiment 2

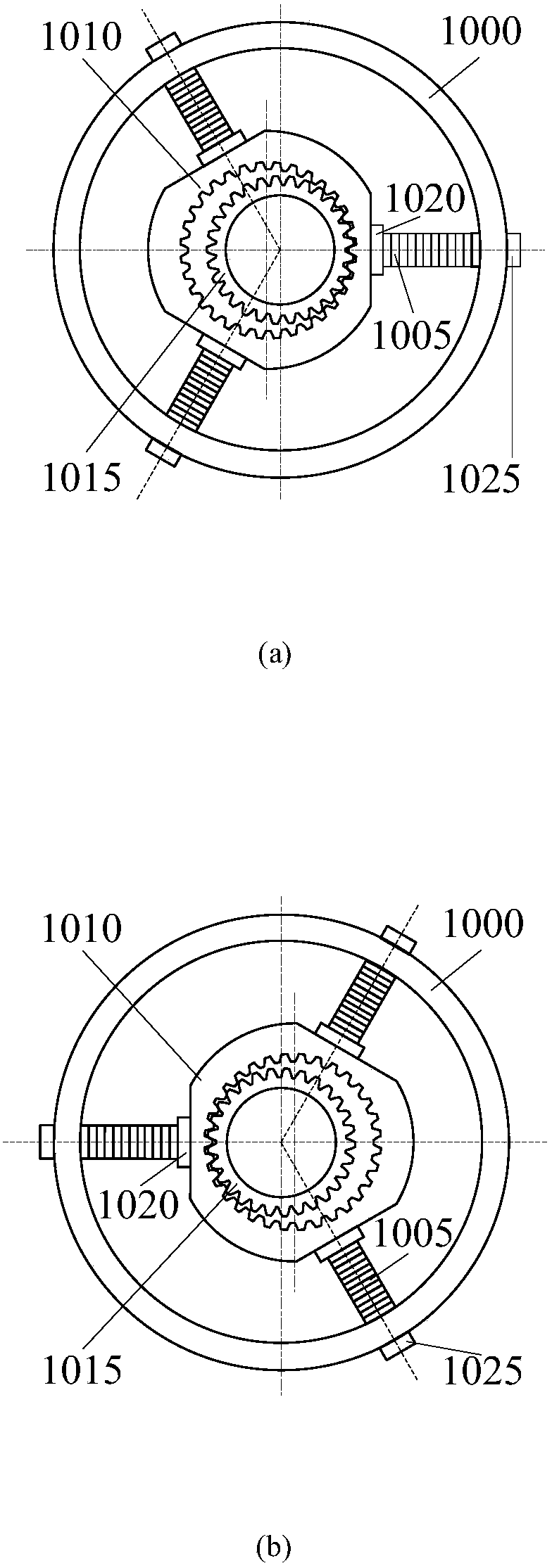

[0054] Combine below figure 1 The scheme in Example 1 is further introduced, see the following description for details:

[0055] Such as figure 1 As shown in (a), this embodiment is composed of a housing 1000 , three piezoelectric actuators 1005 (constituting a first piezoelectric component), an internally toothed stator 1010 and an externally toothed rotor 1015 . Wherein, the laminated piezoelectric actuator 1005 is connected to the casing 1000 through bolts 1025 in the radial direction, and is in sliding contact with the internal tooth stator 1010 . In order to achieve force balance, each piezoelectric actuator 1005 is evenly distributed along the circumferential direction.

[0056] The structure of the second piezoelectric assembly (also composed of three piezoelectric actuators 1005) is basically the same as that of the first piezoelectric assembly, the only difference is the installation position of the piezoelectric actuators 1005, such as figure 1 (b) shown.

[0057...

Embodiment 3

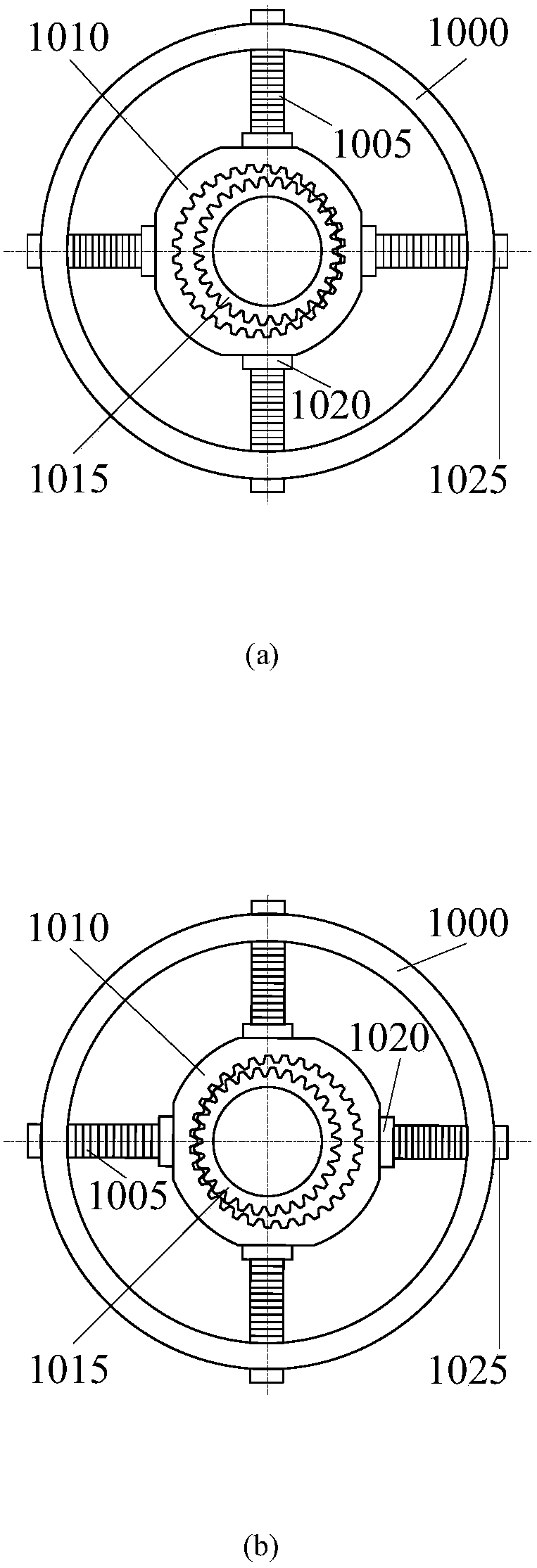

[0065] Combine below figure 2 The scheme in Example 1 is further introduced, see the following description for details:

[0066] Such as figure 2 As shown in (a), this embodiment is composed of a housing 1000 , four piezoelectric actuators 1005 (constituting a first piezoelectric assembly), an inner-toothed stator 1010 and an outer-toothed rotor 1015 . Wherein, the laminated piezoelectric actuator 1005 is connected to the casing 1000 by bolts in the radial direction, and the actuators are evenly distributed and arranged in the circumferential direction.

[0067] The basic structure of the second piezoelectric assembly (also composed of four piezoelectric actuators 1005) is the same as that of the first piezoelectric assembly, and the second piezoelectric assembly is installed after rotating π / 4, as figure 2 (b) shown.

[0068] Under the action of the two piezoelectric components, the meshing force on the external tooth rotor 1015 will be partially offset, and the harmful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com