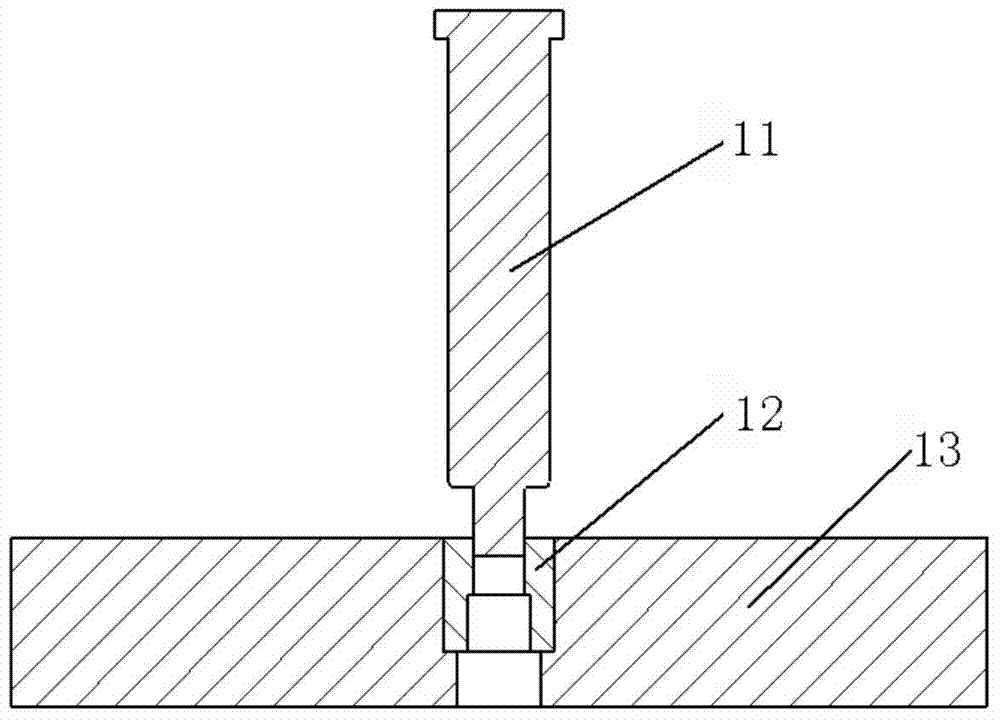

Hole flanging die

A mold and hole-turning technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the cost of mold tooling, increasing the number of mold processes, etc., to reduce the use of molds, reduce production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

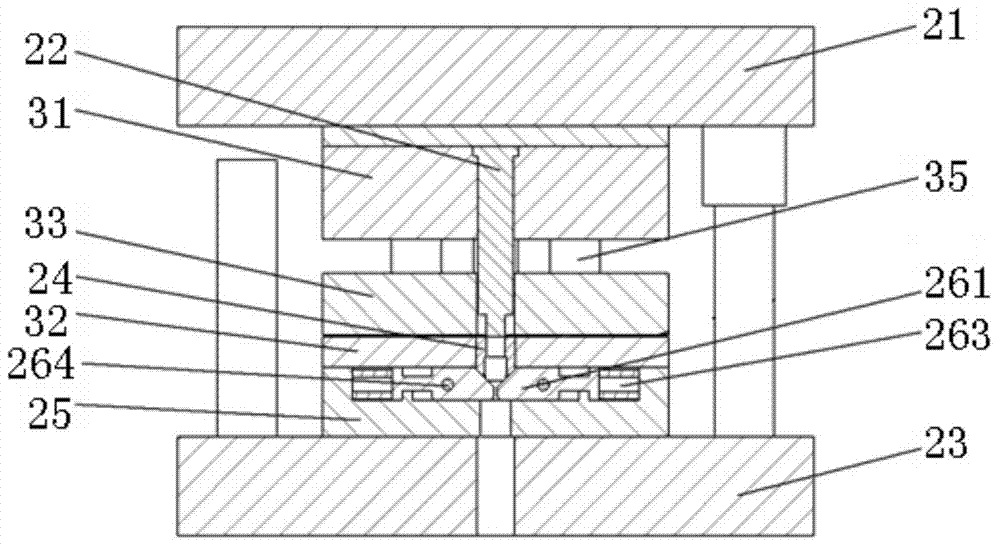

[0040] The core of the present invention is to provide a hole-turning mold, in order to realize the two processes of pre-punching and hole-turning in the same set of molds, thereby reducing the amount of mold usage, reducing the cost of mold tooling, further reducing production costs, and improving production efficiency.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] Such as Figure 2-Figure 10 As shown, in a specific embodiment, the hole-turning die provided by the present invention includes a punch 22 fixed to the upper mold base 21, and a punch that is fixed to the lower mold base 23 and cooperates with the punch 22. Die cover 24; wherein, the punch 22 includes a turning part close to the upper die base 21 and a punching part away from the upper die base 21, and the punching part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com