Environment-friendly high molecular self-adhesive waterproof rolled material

A technology of self-adhesive waterproof membrane and waterproof membrane, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, building insulation materials, etc., can solve the problem of easy pollution, toxic substances, and harm to human health and other issues to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

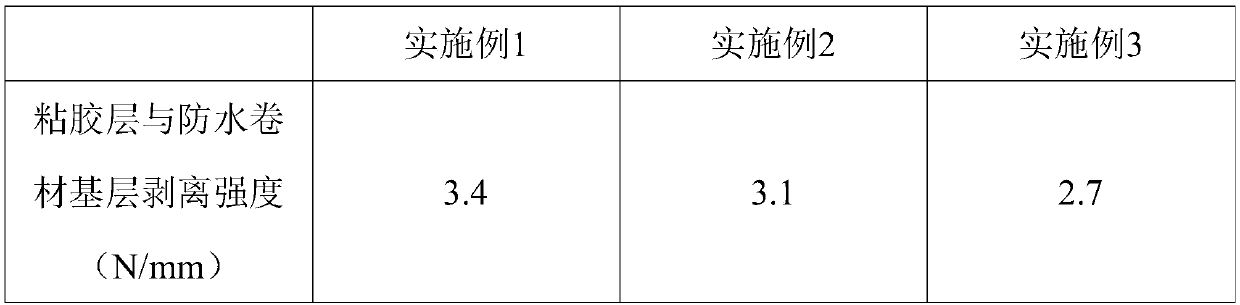

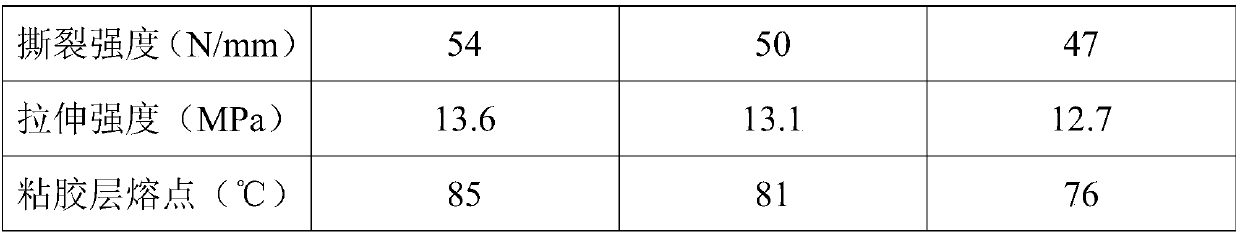

Embodiment 1

[0019] Put 40 parts of phenolic resin, 20 parts of DOP, and 1 part of heat stabilizer into the thermomixer for uniform stirring, set the temperature to 80°C, and stir for 4 minutes, then raise the temperature to 110°C, and put in 2 parts of cycloalkane oil, 10 parts of light calcium carbonate, 0.1 part of antioxidant, 0.1 part of anti-ultraviolet agent, and 3 parts of thermoplastic polyurethane were uniformly stirred, and the stirring time was 5 minutes; all were stirred by a stirrer, and the speed of the stirrer was 600r / min; The material is put into the extruder, and the extruded product is calendered, drawn, and rolled to form the base layer of the waterproof membrane;

[0020] Mix 20 parts of nitrile rubber, 5 parts of carbon black, and 1 part of anti-aging agent at a temperature of 70°C for 10 minutes to obtain a nitrile rubber masterbatch; then add 0.1 part of vulcanizing agent for kneading , and with the aid of a microwave with a power of 500w, the practice time is 10 m...

Embodiment 2

[0024] Put 50 parts of phenolic resin, 25 parts of DOP, and 1.5 parts of heat stabilizer into a thermomixer for uniform stirring, set the temperature to 90°C, and stir for 6 minutes, then raise the temperature to 120°C, and put in 3 parts of cycloalkane Oil, 20 parts of light calcium carbonate, 0.5 part of antioxidant, 0.5 part of anti-ultraviolet agent, 6 parts of thermoplastic polyurethane were stirred evenly, and the stirring time was 8 minutes; The material is put into the extruder, and the extruded product is calendered, drawn, and rolled to form the base layer of the waterproof membrane;

[0025] Add 40 parts of phenolic resin, 3 parts of fibrin, 5 parts of lignocellulose, 10 parts of ethyl acetate, 1 part of polyisobutylene, 3 parts of sodium alginate, 4 parts of tetraethyl silicate, and 15 parts of nitrile rubber into the high-speed In an open mill, blend at a temperature of 90°C to obtain a viscose paste;

[0026] Combining the viscose paste with the base layer of th...

Embodiment 3

[0028] Put 45 parts of phenolic resin, 20 parts of DOP, and 1 part of thermal stabilizer into a thermomixer for uniform stirring, set the temperature at 90°C, and stir for 6 minutes, then raise the temperature to 120°C, and put in 3 parts of cycloalkane Oil, 15 parts of light calcium carbonate, 0.3 part of antioxidant, 0.3 part of anti-ultraviolet agent, 5 parts of thermoplastic polyurethane were stirred evenly, and the stirring time was 6 minutes; The material is put into the extruder, and the extruded product is calendered, drawn, and rolled to form the base layer of the waterproof membrane;

[0029] Add 35 parts of phenolic resin, 2 parts of fibrin, 5 parts of lignocellulose, 10 parts of ethyl acetate, 1 part of polyisobutylene, 3 parts of sodium alginate, and 4 parts of tetraethyl orthosilicate into the high-speed open mixer. Blending at 85°C to obtain viscose paste;

[0030] Combining the viscose paste with the base layer of the waterproof membrane, and setting an anti-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com