Method for preparing high-performance aluminum alloy by means of powder injection molding technology

A technology of powder injection molding and injection molding, which is applied in the field of powder metallurgy, can solve the problems of inability to meet the performance requirements of structural materials, high cost of raw material powder, poor mechanical properties, etc., and achieve uniform microstructure, high material utilization rate, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

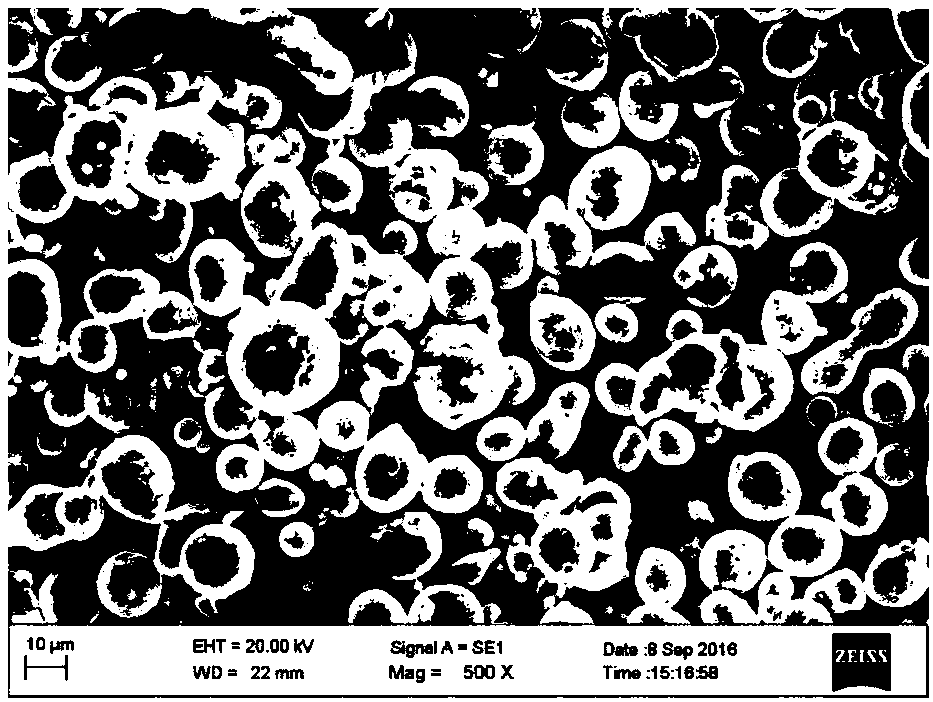

[0034] Example 1: Composition Optimization of Injection Molded Aluminum Alloy System

[0035] (a) Ingredients: Mix the designed elements according to the mass percentage (see Table 1) and then dry mix them on the mixer for 2 hours to obtain premixed powder; the binder is a wax-based binder, and each component is Percent paraffin: beeswax: polyethylene wax: low density polyethylene: stearic acid = 24:24:24:24:4 Weighing, the metering accuracy of powder and binder is 0.1g.

[0036] (b) Feed preparation: weigh the mixed powder and the prepared binder according to the loading capacity of 62%, and place them in the CF-1L type powerful pressurized internal mixer according to the steps for mixing. The refining temperature is 170°C, the rotation speed is 30r / min, and the mixture becomes molten after 1.5-2h. After mixing thoroughly, take it out and cool it.

[0037] (c) Injection molding: After the feed material is crushed, it is poured into the cylinder of the CJ80-E injection machin...

Embodiment 2

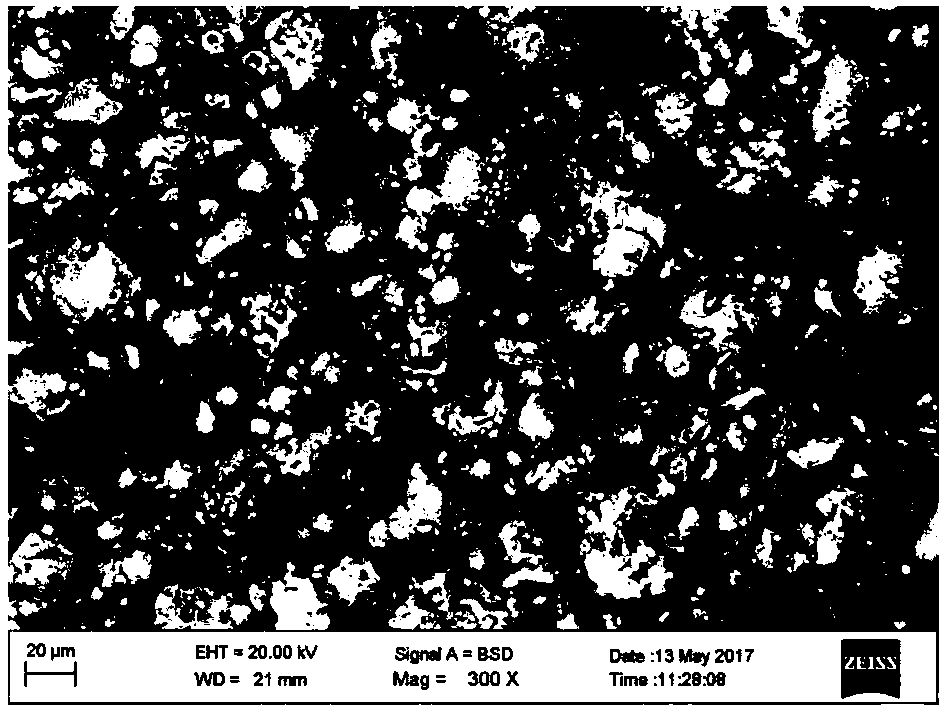

[0042] Example 2: Composition Optimization of Injection Molding Aluminum Alloy Binder System

[0043] (a) Ingredients: The elements of Al-Mg-Cu-Si-Sn are prepared according to the mass percentage of 91.7:1.5:4.6:2.0:0.2, and then dry-mixed on the mixer for 2 hours to obtain pre-mixed powder; the binder is wax Base binder, each component is weighed according to Table 2 by mass percentage, and the metering accuracy of powder and binder is 0.1g.

[0044] (b) Feed preparation: weigh the mixed powder and the prepared binder according to the loading capacity of 62%, and place them in the CF-1L type powerful pressurized internal mixer according to the steps for mixing. The refining temperature is 170°C, the rotation speed is 30r / min, and the mixture becomes molten after 1.5-2h. After mixing thoroughly, take it out and cool it.

[0045] (c) Injection molding: after crushing the feed material, pour it into the cylinder of CJ80-E injection machine for injection operation, compare the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com