High hardness high-chromium alloy wear-resisting balls and preparation method thereof

A high-chromium alloy and wear-resistant ball technology, which is applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of rough crystal structure of wear-resistant balls, increased consumption of wear-resistant balls, poor wear-resistant performance, etc., and achieve uniform structure Strong, wear-resistant, strong dispersion and bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

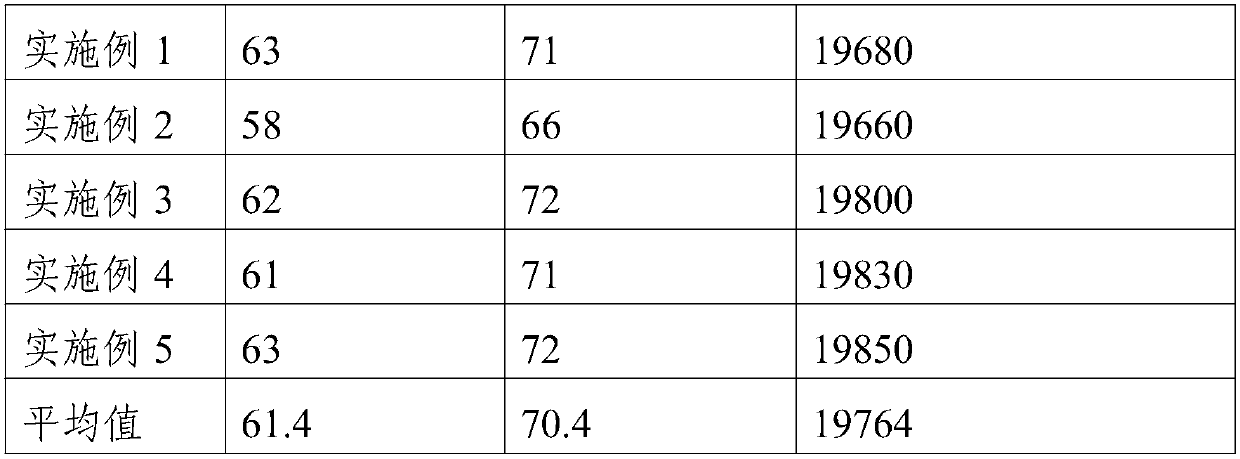

Examples

Embodiment 1

[0021] A high-hardness and high-chromium alloy wear-resistant ball, including the following alloying elements: C2.2%, Si 0.55%, Mn 0.9%, Cr 17%, Cu 0.18%, Mo 0.25%, B 0.12%, Ni 0.46%, the balance is Fe and unavoidable impurities, and the high-hardness high-chromium alloy wear-resistant ball also includes rare earth oxide and nitride fine powder.

[0022] Among them, the rare earth oxide is a mixture of cerium oxide and scandium oxide with a molar ratio of 1:1 accounting for 0.08% of the total mass of the wear-resistant ball; the fine powder of nitride is a mass ratio of 1.5-2% of the total mass of the wear-resistant ball 2: 1-1.5 mixture of silicon nitride and hafnium nitride.

[0023] High hardness and high chromium alloy wear-resistant ball, the preparation steps are as follows:

[0024] 1) Ingredients smelting: Add scrap steel, pig iron, ferromolybdenum, scrap copper, and part of ferromanganese into an intermediate frequency electric furnace, heat and melt, and the melting...

Embodiment 2

[0029] A high-hardness and high-chromium alloy wear-resistant ball, including the following alloying elements: C2.36%, Si 0.6%, Mn 0.8%, Cr 16.5%, Cu 0.21%, Mo 0.32%, B 0.1%, Ni 0.55%, the balance is Fe and unavoidable impurities, and the high-hardness high-chromium alloy wear-resistant ball also includes rare earth oxide and nitride fine powder.

[0030] Among them, the rare earth oxide is a mixture of cerium oxide and scandium oxide with a molar ratio of 1:1 accounting for 0.1% of the total mass of the wear-resistant ball; the fine powder of nitride is a mixture of 1.8% of the total mass of the wear-resistant ball A mixture of silicon nitride and hafnium nitride.

[0031] High hardness and high chromium alloy wear-resistant ball, the preparation steps are as follows:

[0032] 1) Ingredients smelting: Add scrap steel, pig iron, ferromolybdenum, scrap copper, and part of ferromanganese into an intermediate frequency electric furnace, heat and melt, and the melting temperature...

Embodiment 3

[0037] A high-hardness high-chromium alloy wear-resistant ball, including the following alloy elements: C2.42%, Si 0.6%, Mn 1%, Cr 18%, Cu 0.22%, Mo 0.33%, B 0.18%, Ni 0.5%, the balance is Fe and unavoidable impurities, and the high-hardness high-chromium alloy wear-resistant ball also includes rare earth oxide and nitride fine powder.

[0038] Among them, the rare earth oxide is a mixture of cerium oxide and scandium oxide with a molar ratio of 1:1 accounting for 0.14% of the total mass of the wear-resistant ball; the fine powder of nitride is a mixture of 1.6% of the total mass of the wear-resistant ball A mixture of silicon nitride and hafnium nitride.

[0039] High hardness and high chromium alloy wear-resistant ball, the preparation steps are as follows:

[0040] 1) Ingredients smelting: Add scrap steel, pig iron, ferromolybdenum, scrap copper, and part of ferromanganese into an intermediate frequency electric furnace, heat and melt, and the melting temperature is 1580 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com