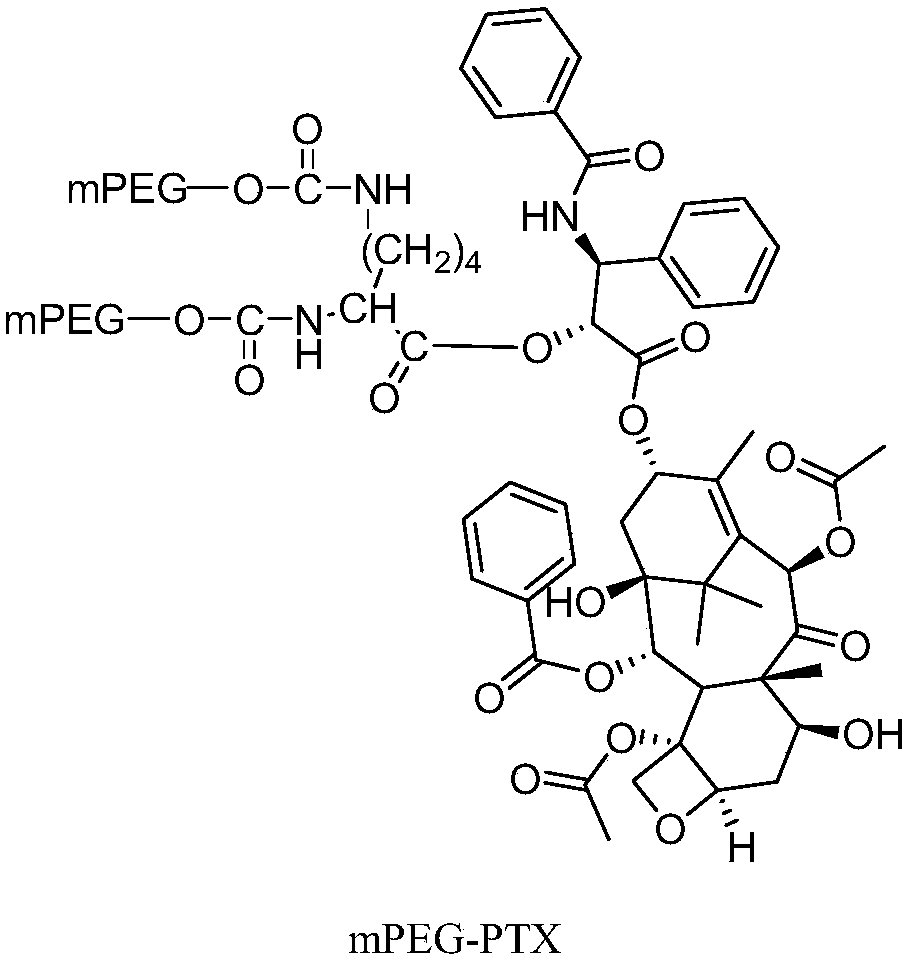

Polyethylene glycol modified paclitaxel, and preparation method and application thereof

A technology of polyethylene glycol and paclitaxel, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as unsatisfactory effects of improving water solubility and bioavailability, and achieves High bioavailability, easy operation, improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

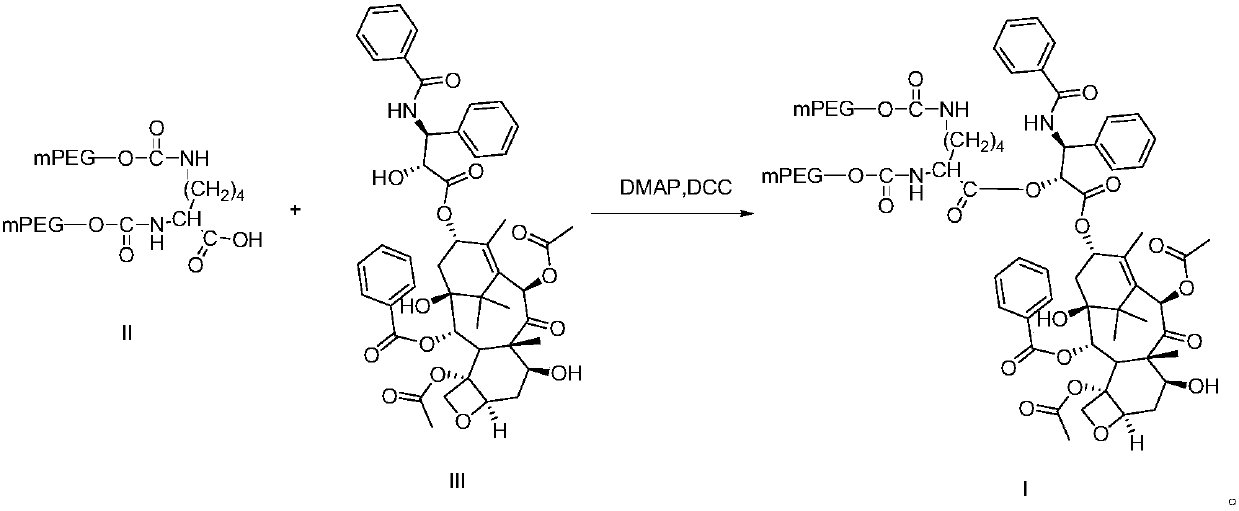

[0016] Preparation of Compound I-1:

[0017]

[0018] In the above formula, the molecular weight of mPEG is 800.

[0019] Add II (1g) and PTX (0.5g) into dichloromethane (40ml), stir to dissolve, then add catalytic amounts of DMAP and DCC (0.13g) respectively, under argon protection, stir at room temperature for 24 hours, TLC plate detection The raw material PTX reacted completely. Filtrate, pour the filtrate into cold ether to obtain a white precipitate, filter, and vacuum-dry the filter cake to obtain a branched polyethylene glycol-modified paclitaxel compound (mPEG-PTX) white powder, re-dissolve the obtained solid in dichloromethane , then concentrated to 1ml, then added isopropanol to separate out a white solid (1.04g, yield 74%, paclitaxel content 32%), which is the target product I.

Embodiment 2

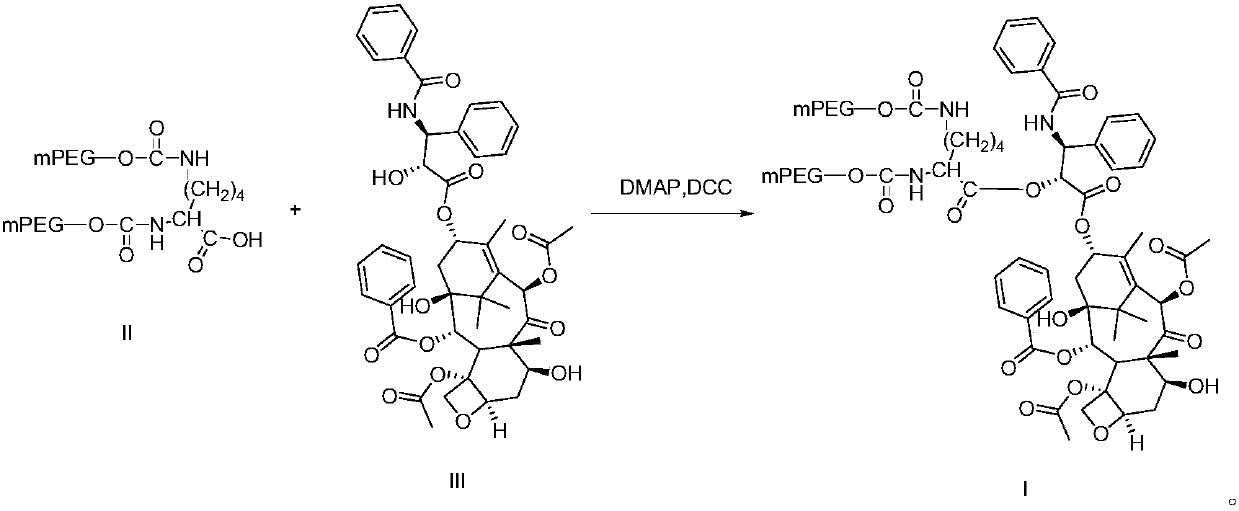

[0021] Preparation of Compound I-2:

[0022]

[0023] In the above formula, the molecular weight of mPEG is 1600.

[0024] Add II (1g) and PTX (0.25g) into dichloromethane (30ml), stir to dissolve, then add catalytic amounts of DMAP and DCC (0.09g) respectively, under argon protection, stir at room temperature for 24 hours, TLC plate detection The raw material PTX reacted completely. Filtrate, pour the filtrate into cold ether to obtain a white precipitate, filter, and vacuum-dry the filter cake to obtain a branched polyethylene glycol-modified paclitaxel compound (mPEG-PTX) white powder, re-dissolve the obtained solid in dichloromethane , then concentrated to 1ml, then added isopropanol to separate out a white solid (0.81g, yield 64.8%, paclitaxel content 19.2%), which is the target product I.

Embodiment 3

[0026] Preparation of Compound I-3:

[0027]

[0028] In the above formula, the molecular weight of mPEG is 2000.

[0029] Add II (2g) and PTX (0.3g) into dichloromethane (34ml), stir to dissolve, then add catalytic amounts of DMAP and DCC (1.2g) respectively, under argon protection, stir at room temperature for 24 hours, TLC plate detection The raw material PTX reacted completely. Filtrate, pour the filtrate into cold ether to obtain a white precipitate, filter, and vacuum-dry the filter cake to obtain a branched polyethylene glycol-modified paclitaxel compound (mPEG-PTX) white powder, re-dissolve the obtained solid in dichloromethane , then concentrated to 1ml, then added isopropanol to separate out a white solid (1.6g, yield 79%, paclitaxel content 12.8%), which is the target product I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com