(Ti,M)C nano solid solution powder and preparation method thereof

A solid solution and powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of high synthesis temperature of carbide powder, achieve easy carbon content, stable process, and precise control of carbon content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

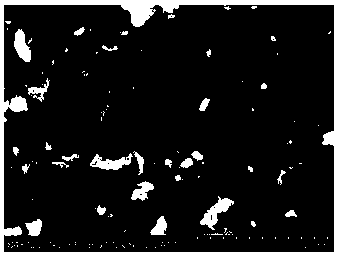

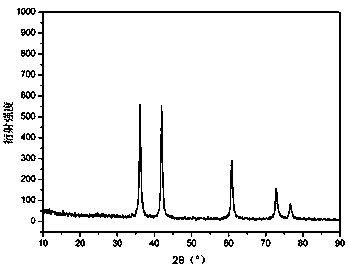

Image

Examples

Embodiment 1

[0021] In this embodiment, (Ti, M) C solid solution powder is prepared with Ti powder, W powder and carbon black powder, and the steps are as follows:

[0022] (1) Put 25.98g of Ti powder, 14g of W powder, and 10.02g of carbon black powder into a ball mill tank filled with 60mL of absolute ethanol, and perform high-energy ball milling for 6 hours with a ball-to-material ratio of 15:1 and a milling speed of 600 rpm / min, wherein Ti powder, W powder, carbon black powder particle size is -200 mesh;

[0023] (2) After ball milling, place the mixed slurry in a vacuum drying oven and dry at 50°C for 3 hours to obtain a highly reactive block mixture;

[0024] (3) Fill the 1 / 4 volume of the ceramic crucible with the above block mixture, and cover and fill the upper layer of the crucible with NaCl and KCl mixed powder with a molar ratio of 1:1; In the muffle furnace, keep warm at 900°C for 4 hours to carry out carbonization and solid solution reaction, and generate carbide solid solut...

Embodiment 2

[0028] In this embodiment, (Ti, M) C solid solution powder is prepared with Ti powder, Mo powder, Nb powder and carbon black powder, and the steps are as follows:

[0029] (1) Put 33.98g of Ti powder, 4g of Mo powder, 2g of Nb powder, and 10.02g of carbon black powder into a ball mill tank filled with 60mL of absolute ethanol, and perform high-energy ball milling for 8 hours with a ball-to-material ratio of 10:1. The rotating speed is 450 revs / min, wherein the Ti powder, Mo powder, Nb powder, and carbon black powder have a particle size of -250 mesh;

[0030] (2) After ball milling, place the mixed slurry in a vacuum drying oven and dry at 80°C for 1 hour to obtain a highly reactive block mixture;

[0031] (3) Fill 1 / 3 of the volume of the ceramic crucible with the above block mixture, and use NaCl and BaCl with a molar ratio of 1:1 2 The mixed powder covers and fills the upper layer of the crucible; then the crucible is tightly covered and placed in a muffle furnace with a f...

Embodiment 3

[0034] In this embodiment, (Ti, M) C solid solution powder is prepared from Ti powder, Ta powder, Cr powder, V powder and carbon black powder, and the steps are as follows:

[0035] (1) Put 36.78g of Ti powder, 2g of Ta powder, 1.2g of Cr powder, 0.4g of V powder and 10.02g of carbon black powder into a ball mill tank filled with 60mL of absolute ethanol, and perform high-energy ball milling for 10 hours. The ratio is 12:1, the ball milling speed is 300 rpm, and the particle sizes of Ti powder, Ta powder, Cr powder, V powder and carbon black powder are all -325 mesh;

[0036] (2) After ball milling, place the mixed slurry in a vacuum drying oven and dry at 80°C for 1 hour to obtain a highly reactive block mixture;

[0037] (3) Fill the 1 / 2 volume of the ceramic crucible with the above block mixture, cover and fill the upper layer of the crucible with NaCl powder; then cover the crucible tightly and place it in a muffle furnace with a flowing Ar atmosphere, at 1000 °C Insulate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com