Metal-based surface composite material and preparation method thereof

A surface composite material and metal-based technology, which is applied in the field of metal material manufacturing, can solve the problems of holes in the composite layer, poor bonding between the composite layer and the matrix, and poor particle uniformity, and achieves high efficiency, good bonding, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

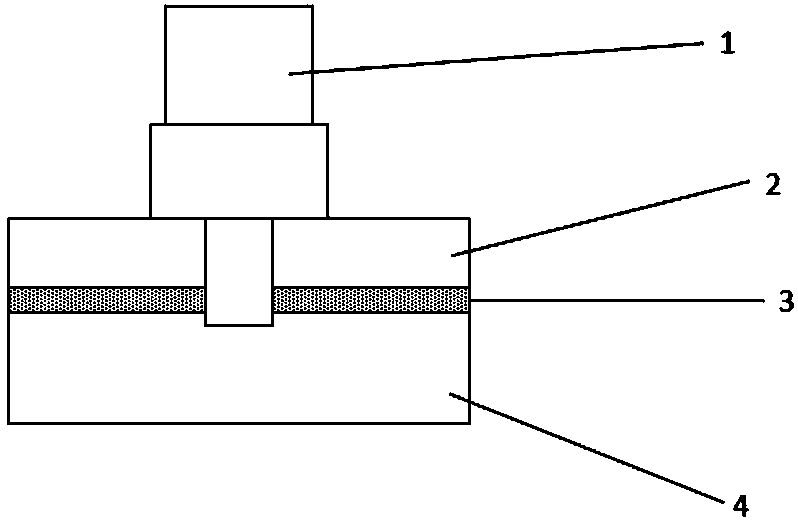

[0050] The suspension of 1um silicon carbide particles and polyvinyl alcohol aqueous solution is evenly coated on the lower aluminum alloy plate with a thickness of 5mm, and the coating thickness is 0.1mm, and then the lower aluminum alloy plate is covered with a 3mm thick upper metal cover plate. The friction stir welding machine performs friction stir processing on the upper cladding plate under the technological conditions of a welding speed of 30 mm / min, a rotational speed of 950 rpm, and a stirring head needle of 3.5 mm.

Embodiment 2

[0052] The suspension of 60um zirconia particles and glutinous rice glue aqueous solution is evenly coated on the lower copper alloy plate with a thickness of 7mm, and the coating thickness is 0.6mm, and then the lower copper alloy plate is covered with a 2mm thick upper metal cover plate. The friction welding machine performs friction stir processing on the upper cladding plate under the technological conditions of a welding speed of 200 mm / min, a rotational speed of 2500 rpm, and a stirring head needle of 3.5 mm.

Embodiment 3

[0054] The suspension of 40um alumina particles and polyethylene glycol aqueous solution was evenly coated on the lower magnesium alloy plate with a thickness of 9mm to make the thickness of 0.1mm, and then the lower magnesium alloy plate was covered with a 4mm thick upper metal cladding plate. Friction stir processing is performed on the upper cladding plate under the technological conditions of a friction stir welding machine at a welding speed of 30 mm / min, a rotational speed of 950 rpm, and a stirring head needle of 3.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com