Flue gas treatment fluid special for hot chamber die casting machine

A hot-chamber die-casting machine and flue gas treatment technology, used in gas treatment, use of liquid separators, dispersed particle filtration, etc., can solve the problems of liver enlargement, injury, and high incidence of sore throat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Flue gas treatment fluid for hot chamber die-casting machines, made of the following raw materials in parts by weight: 100-150 parts of deionized water, 10-15 parts of methyl isobutyl ketone, 5-8 parts of zeolite powder, and 5 parts of dehydrated malic anhydride -12 parts, 20-40 parts of xylene, 15-25 parts of n-butanol, 4-8 parts of dimethylformamide, 10-15 parts of ethylene glycol, 3-9 parts of triisopropylbenzene, 5 parts of citric acid -12 parts, 2-8 parts of sodium hypochlorite, 6-12 parts of naphthalene ethylenediamine hydrochloride, 2-4 parts of cocoyl monoethanolamine, 1-5 parts of trimethylpentane, 2-8 parts of isooctane, pyrophosphoric acid 1-3 parts of sodium, 1-2 parts of sulfonated cobalt phthalocyanine, 2-4 parts of hexamethylphosphoramide, 5-12 parts of composite fiber, 6-15 parts of composite colloid.

[0022] Further, the preferred parts by weight of each raw material are: 120 parts of deionized water, 12 parts of methyl isobutyl ketone, 6 parts of zeol...

Embodiment 2

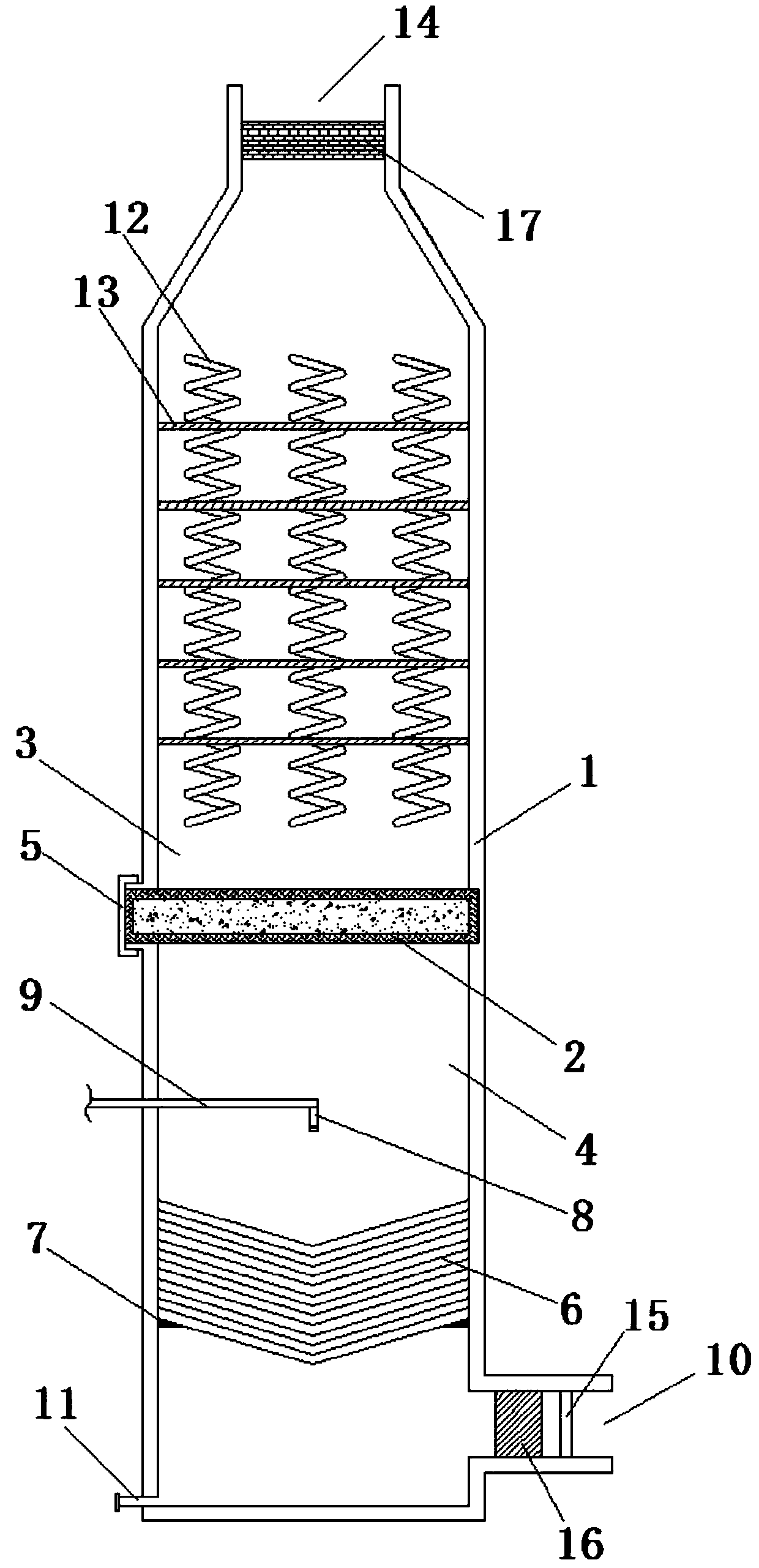

[0026] Such as figure 1 As shown, a hot chamber die-casting machine flue gas purification device containing the above-mentioned flue gas treatment liquid includes a purification tower 1, the cross section of the purification tower 1 is square, and a filter box 2 is arranged in the middle of the purification tower 1, The outer wall of the filter box 2 is a hollow structure, and the inside of the filter box 2 is equipped with a mixed adsorbent, and the filter box 2 divides the purification tower 1 into an upper part of the photolysis chamber 3 and a lower part of the absorption chamber 4;

[0027] The filter box 2 is a drawer-type structure, which can be inserted and extracted from the side wall of the purification tower 1, so as to facilitate the replacement of the mixed adsorbent inside it, and it is locked by the sealing cover 5 after insertion;

[0028] The absorption cavity 4 is provided with multi-layered ceramic corrugated packing 6, the ceramic corrugated packing 6 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com