Preparation method of aluminum alloy bionic anti-icing surface

An aluminum alloy surface, aluminum alloy technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of human body and environmental hazards, high corrosion of electrolyte, complicated preparation process, etc., and achieve low environmental hazards , good anti-icing performance and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

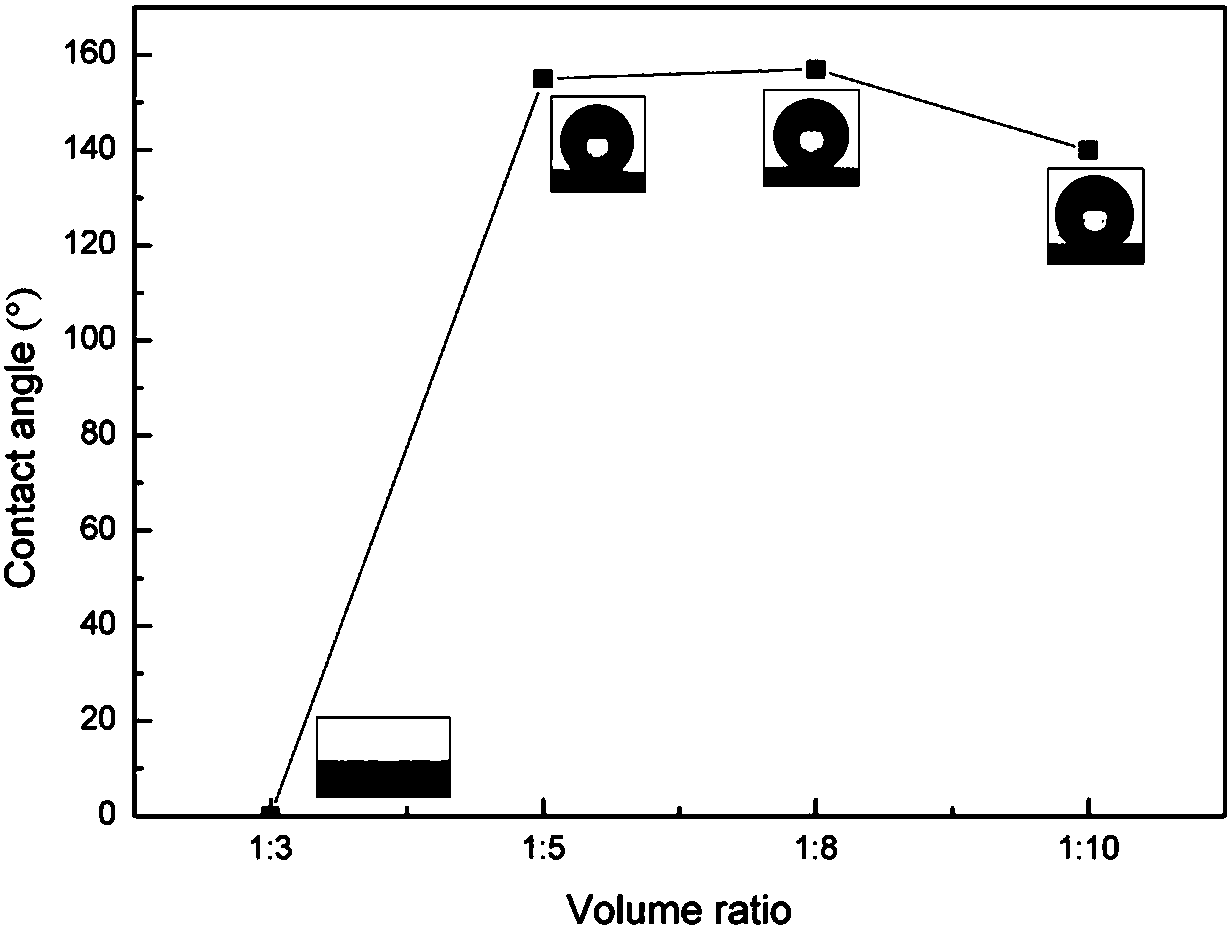

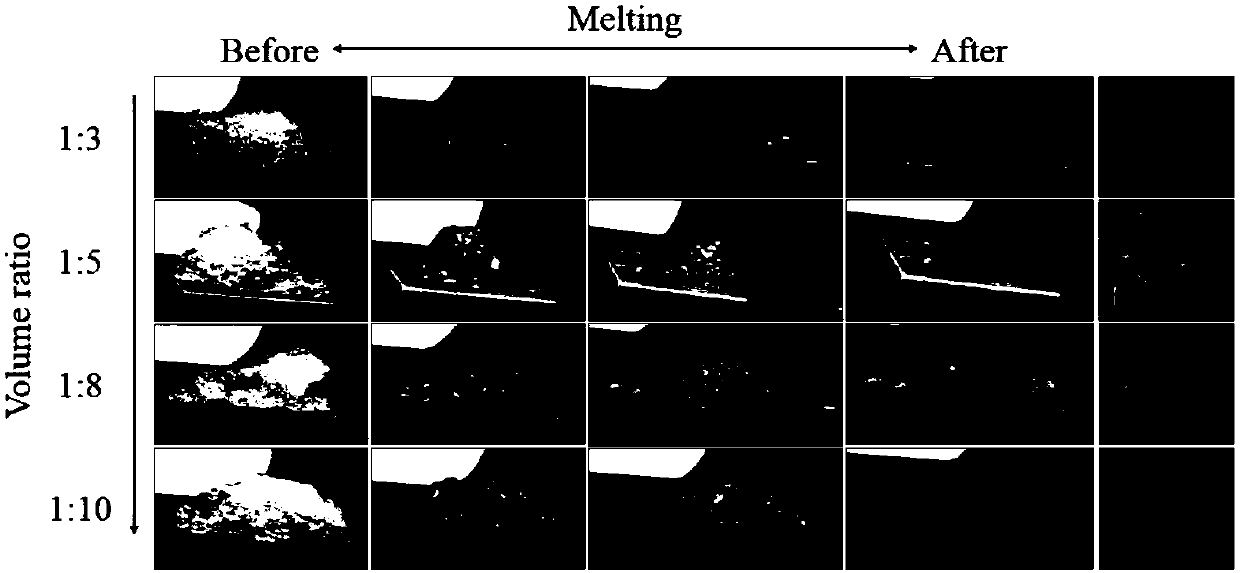

Embodiment 1

[0029] A method for preparing an aluminum alloy bionic anti-icing surface, the specific steps are as follows:

[0030] A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, 2000# sandpaper in turn to remove the surface oxide layer, and the polished aluminum alloy surface is placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning , to remove dirt on the surface;

[0031] B. Preparation of surface micro-nano hierarchical structure: use a laser engraving machine to perform laser ablation on the pretreated aluminum alloy surface to prepare an aluminum alloy surface with a microstructure. The microscopic surface is a cylindrical array structure with a diameter of 30 μm, and two adjacent The distance between the centers of the cylinders is 80 μm, and the height of a single cylinder is 80 μm;

[0032] Then place the aluminum alloy surface with microstructure in acetone, absolute ethanol and distilled water for...

Embodiment 2

[0035] A method for preparing an aluminum alloy bionic anti-icing surface, the specific steps are as follows:

[0036]A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, 2000# sandpaper in turn to remove the surface oxide layer, and the polished aluminum alloy surface is placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning , to remove dirt on the surface;

[0037] B. Preparation of surface micro-nano hierarchical structure: use a laser engraving machine to perform laser ablation on the pretreated aluminum alloy surface to prepare an aluminum alloy surface with a microstructure. The microscopic surface is a cylindrical array structure with a diameter of 60 μm, and two adjacent The distance between the centers of the cylinders is 120 μm, and the height of a single cylinder is 80 μm;

[0038] Then place the aluminum alloy surface with microstructure in acetone, absolute ethanol and distilled water for...

Embodiment 3

[0041] A method for preparing an aluminum alloy bionic anti-icing surface, the specific steps are as follows:

[0042] A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, 2000# sandpaper in turn to remove the surface oxide layer, and the polished aluminum alloy surface is placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning , to remove dirt on the surface;

[0043] B. Preparation of surface micro-nano hierarchical structure: use a laser engraving machine to perform laser ablation on the pretreated aluminum alloy surface to prepare an aluminum alloy surface with a microstructure. The microscopic surface is a cylindrical array structure with a diameter of 80 μm, and two adjacent The distance between the centers of the cylinders is 150 μm, and the height of a single cylinder is 80 μm;

[0044] Then place the aluminum alloy surface with microstructure in acetone, absolute ethanol and distilled water fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com