Phosphorus-nitrogen synergistic self-flame-retardant acrylic emulsion and preparation method thereof

A technology of acrylic emulsion and acrylic acid, which is applied in the direction of fireproof coatings, etc., can solve the problems of great harm to the human body, and achieve the effect of not easy to dissociate and lasting flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

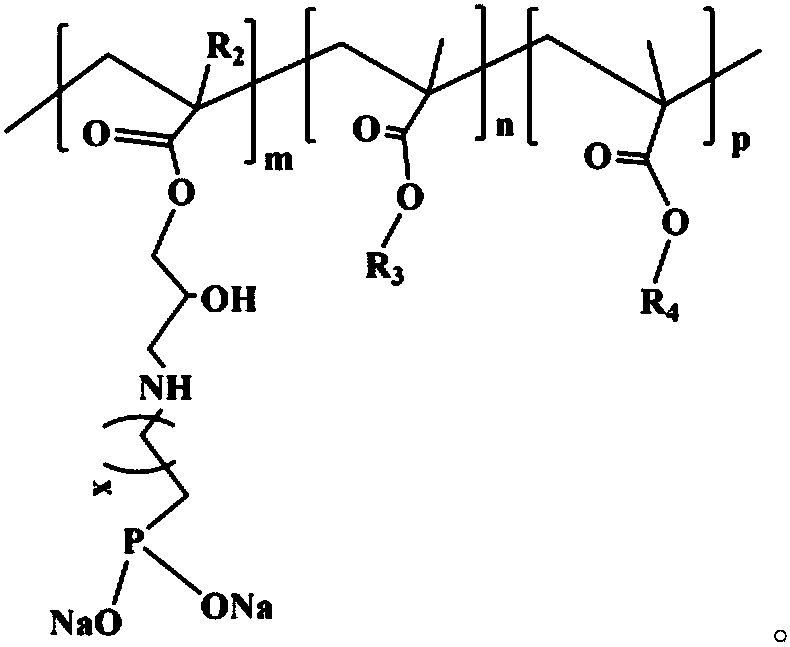

Image

Examples

Embodiment 1

[0024] a. Synthesis of phosphorus-nitrogen synergistic self-flame-retardant monomer: Add dimethyl amine ethyl phosphate and glycidyl methacrylate in a molar ratio of 1:1 to the reactor, add 30 parts of ethyl acetate to dissolve, Heat to 80°C for 3 hours and cool to room temperature; then add 30 parts of 2% sodium hydroxide aqueous solution and stir to extract the water layer, dry and wash to obtain a phosphorus-nitrogen synergistic self-flame retardant monomer.

[0025] b. Seed emulsion polymerization: Add 40 parts of deionized water, 2 parts of vinyl polyethylene glycol, and 4 parts of methacrylic acid in a four-port reaction vessel equipped with a speed-adjustable stirrer, a return pipe, a dropping funnel and a thermometer Methyl ester, 5 parts of soft butyl methacrylate, 1 part of hydroxyethyl methacrylate, 2 parts of pH sodium bicarbonate solution; emulsify under high-speed stirring at 1300-1500r / min to obtain milky white pre-emulsified mixed monomer emulsion; heat up When...

Embodiment 2

[0028] a. Add diethyl aminopropyl phosphate and glycidyl methacrylate into the reactor at a molar ratio of 1:1, add 30 parts of ethyl acetate to dissolve, heat to 40°C for 4 hours and cool to room temperature; then Add 20 parts of 2% sodium hydroxide aqueous solution, stir and extract the water layer, dry and wash to obtain a phosphorus-nitrogen synergistic self-flame retardant monomer.

[0029] b. Seed emulsion polymerization: In a four-port reaction vessel equipped with a speed-adjusting stirrer, a reflux pipe, a dropping funnel and a thermometer, add 45 parts of deionized water, 2 parts of allyl-2-propyl sodium ethanesulfonate, 4 parts of methyl acrylate, 2 parts of butyl methacrylate, 2 parts of hydroxyethyl methacrylate, 1.5 parts of ammonia water; emulsify under high-speed stirring at 1500r / min to obtain a milky white pre-emulsified mixed monomer emulsion; when the temperature is raised to 80°C Reduce the speed to 800r / min, add dropwise 1.5 parts of 10% ammonium persulfa...

Embodiment 3

[0032] a. Synthesis of phosphorus-nitrogen synergistic self-flame retardant monomer: Add dimethyl aminopropyl phosphate and glycidyl acrylate in a molar ratio of 1:1 to the reactor, add 30 parts of ethyl acetate to dissolve, heat to 60 After reacting at ℃ for 3.5 hours, cool to room temperature; then add 35 parts of 2% sodium hydroxide aqueous solution, stir and extract the water layer, dry and wash to obtain a phosphorus-nitrogen synergistic self-flame retardant monomer.

[0033] b. Seed emulsion polymerization: Add 38 parts of deionized water, 1 part of octadecyl dimethyl vinyl phenyl chloride ammonium, 4.5 parts of methyl methacrylate, 5 parts of propyl acrylate, and 3 parts of ammonia water; emulsify under high-speed stirring at 1000r / min to obtain a milky white pre-emulsified mixed monomer emulsion; when the temperature rises to 75°C, reduce the speed to 800r / min min, 1.5 parts of 10% potassium persulfate solution was added dropwise to initiate the reaction at 80°C for 2h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com