Electroplating solution and electroplating method and application thereof

A technology of electroplating solution and compound, which is applied in electroplating solution and its electroplating method and application field, can solve the problems of ignoring the properties of electroplating solution, etc., and achieve the effect of improving hole filling ability, better deep plating ability, and fine crystallization of plating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

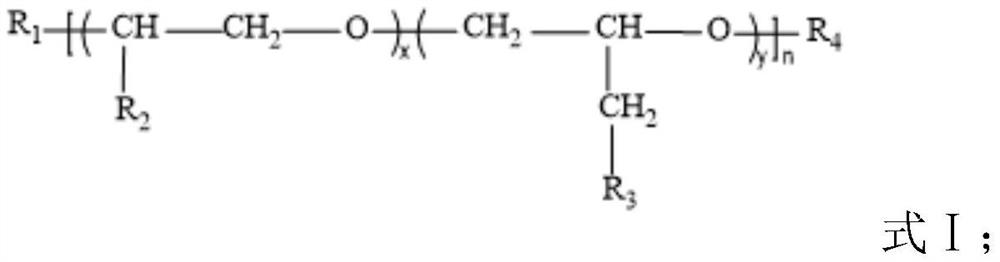

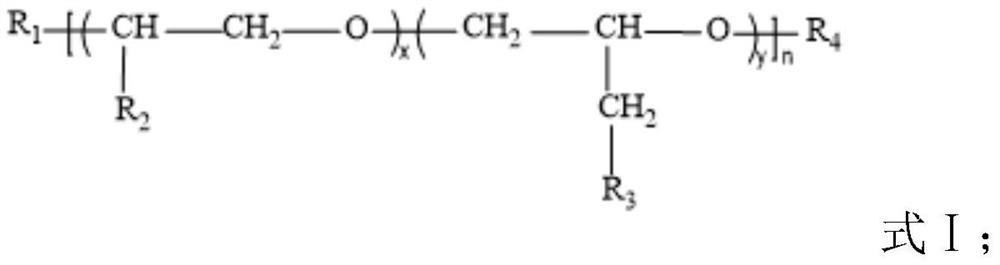

[0054] This embodiment provides a kind of electroplating liquid, and described electroplating liquid is made up of following components according to mass concentration: sulfuric acid 200g / L, copper sulfate 60g / L, sodium chloride 100mg / L, tetravalent vanadium compound VOSO 4 (the mass concentration of tetravalent vanadium is 50g / L), pentavalent vanadium compound V 2 o 5 (the mass concentration of pentavalent vanadium 5g / L), surfactant 500mg / L (as shown in formula I, R 1 is methyl, R 2 for hydrogen, R 3 is methyl, R 4 is hydrogen, x=24, y=36, n=3, number average molecular weight is 10852g / mol), brightener 5mg / L (sodium 3-mercaptopropane sulfonate) and carrier 500mg / L (polypropylene glycol, number average The molecular weight is 20000 g / mol).

[0055] This embodiment also provides an electroplating layer, which is obtained by pulse electroplating with the electroplating solution.

[0056] The electroplating method of above-mentioned electroplating layer is as follows:

[0...

Embodiment 2

[0059] This embodiment provides a kind of electroplating liquid, and described electroplating liquid is made up of following components according to mass concentration: sulfuric acid 50g / L, copper sulfate 15g / L, sodium chloride 5mg / L, tetravalent vanadium compound V 2 o 4 (The mass concentration of tetravalent vanadium is 1g / L), the pentavalent vanadium compound NaVO 3 (the mass concentration of pentavalent vanadium is 0.5g / L), surfactant 10mg / L (as shown in formula I, R 1 is C10 alkyl, R 2 is C5 alkenyl, R 3 is hydroxyl, R 4 C12 alkoxy group, x=2, y=5, n=25), brightener 0.5mg / L (sodium N,N-dimethyldithiocarbonylpropane sulfonate) and carrier 10mg / L (poly Ethylene glycol, the number average molecular weight is 400g / mol).

[0060] This embodiment also provides an electroplating layer, which is obtained by pulse electroplating with the electroplating solution.

[0061] The electroplating method of above-mentioned electroplating layer is as follows:

[0062] Immerse the pl...

Embodiment 3

[0064] This embodiment provides a kind of electroplating liquid, and described electroplating liquid is made up of following components according to mass concentration: sulfuric acid 350g / L, copper sulfate 100g / L, sodium chloride 200mg / L, tetravalent vanadium compound: mass ratio is 1 : 1 VOSO 4 and V 2 o 4 (The mass concentration of tetravalent vanadium is 100g / L), pentavalent vanadium compound: NaVO with a mass ratio of 1:1 3 and NH 4 VO 3 (mass concentration of pentavalent vanadium 10g / L), surfactant 1000mg / L (as shown in formula I, R 1 is C16 cycloalkyl, R 2 is ethyl, R 3 for hydrogen, R 4 C4 alkoxy, x=15, y=40, n=5), brightener 10mg / L (mass ratio of 2:1 isothiuronium propanesulfonic acid inner salt and 3-(benzothiazole-2- mercapto)-sodium propanesulfonate) and carrier 1000mg / L (polyethylene glycol, number average molecular weight 40000g / mol).

[0065] This embodiment also provides an electroplating layer, which is obtained by pulse electroplating with the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com