Accelerator for concrete spraying construction and preparation method thereof

A technology of shotcrete and quick-setting agent, applied in the field of concrete additives, can solve the problems of unfavorable construction quick-setting agent storage, reducing concrete durability, easy precipitation and other problems, achieving excellent quick-setting effect, improving the uniformity of mixture, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

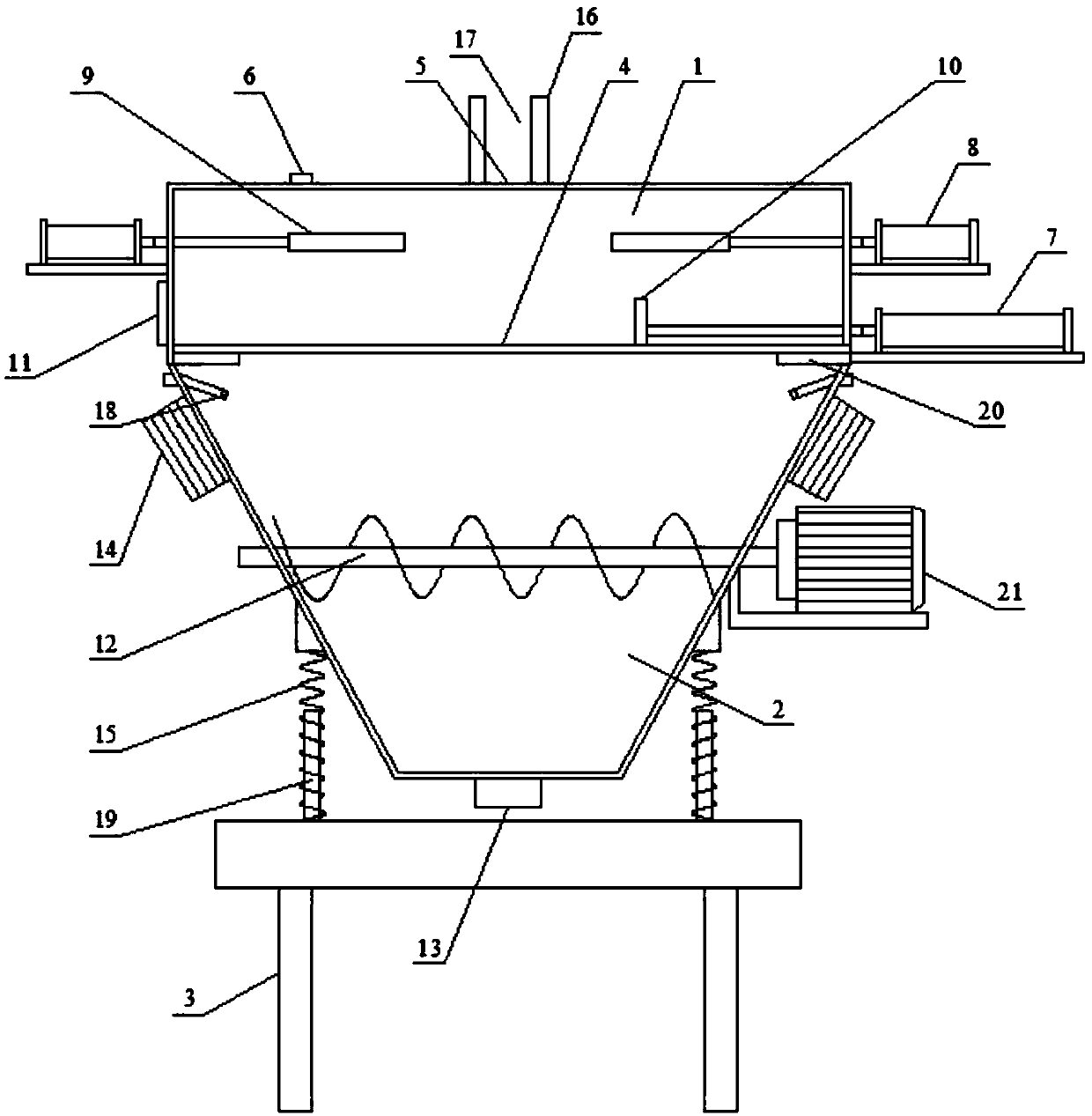

Method used

Image

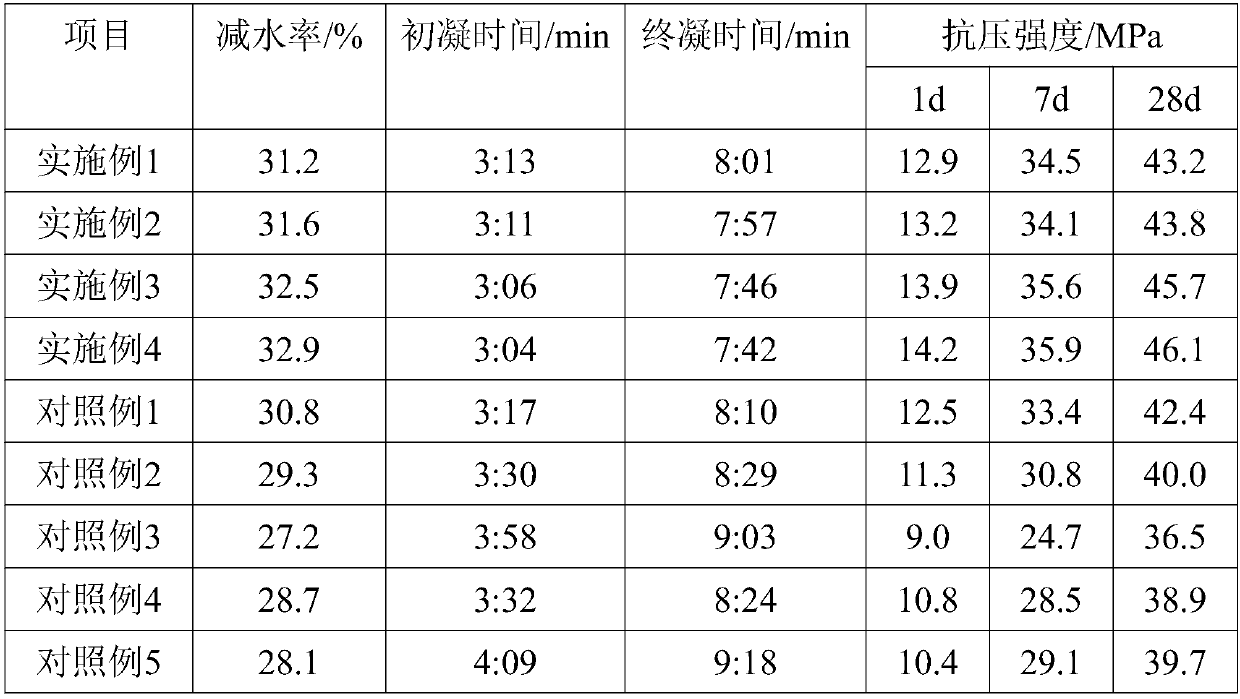

Examples

Embodiment 1

[0041](1) Add water to 40g of soil-grade polyglutamic acid under stirring until completely dissolved, add dropwise 2.5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 20g of polyethylene glycol monomethyl ether 750, add water Until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heated to reflux state and kept stirring for 3 hours, the resulting mixture was concentrated under reduced pressure into a paste with a solid content of 45-55%, and cooled to 0 at a cooling rate of 5°C / min. Insulate and stir at -5°C for 30 minutes, and finally send it to a freeze dryer, and dry the obtained solid to make a fine powder through an ultrafine pulverizer, that is, polyglutamic acid / polyethylene glycol monomethyl ether;

[0042] (2) Heat polyglutamic acid / polyethylene glycol monomethyl ether to 115-125°C and keep stirring for 10 minutes, then add 5g of trimethylolpropane triacrylate and 3g of trimethylolpropane triglycidyl ether, Continue t...

Embodiment 2

[0047] (1) Add water to 45g of soil-grade polyglutamic acid under stirring until completely dissolved, add dropwise 2.5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 25g of polyethylene glycol monomethyl ether 750, add water Until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heated to reflux state and kept stirring for 4 hours, the resulting mixture was concentrated under reduced pressure into a paste with a solid content of 45-55%, and cooled to 0 at a cooling rate of 5°C / min. Insulate and stir at -5°C for 30 minutes, and finally send it to a freeze dryer, and dry the obtained solid to make a fine powder through an ultrafine pulverizer, that is, polyglutamic acid / polyethylene glycol monomethyl ether;

[0048] (2) Heat the polyglutamic acid / polyethylene glycol monomethyl ether to 115-125° C. and keep stirring for 10 minutes, and add 10 g of trimethylolpropane triacrylate and 5 g of trimethylolpropane triglycidyl ether, C...

Embodiment 3

[0053] (1) Add water to 40g of soil-grade polyglutamic acid under stirring until completely dissolved, add dropwise 2.5wt% dilute sulfuric acid solution to adjust the pH value to 3-4, then add 20g of polyethylene glycol monomethyl ether 750, add water Until the polyethylene glycol monomethyl ether 750 is completely dissolved, then heated to reflux state and kept stirring for 3 hours, the resulting mixture was concentrated under reduced pressure into a paste with a solid content of 45-55%, and cooled to 0 at a cooling rate of 5°C / min. Insulate and stir at -5°C for 30 minutes, and finally send it to a freeze dryer, and dry the obtained solid to make a fine powder through an ultrafine pulverizer, that is, polyglutamic acid / polyethylene glycol monomethyl ether;

[0054] (2) Heat polyglutamic acid / polyethylene glycol monomethyl ether to 115-125°C and keep stirring for 10 minutes, then add 5g of trimethylolpropane triacrylate and 3g of trimethylolpropane triglycidyl ether, Continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com