A kind of colored high-strength polymer cement water-resistant mortar and its preparation method

A polymer and mortar technology, applied in the field of building materials, can solve the problems that the performance of building materials cannot meet people's requirements, achieve the effect of small strength loss, good water resistance, and increase the strength of mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

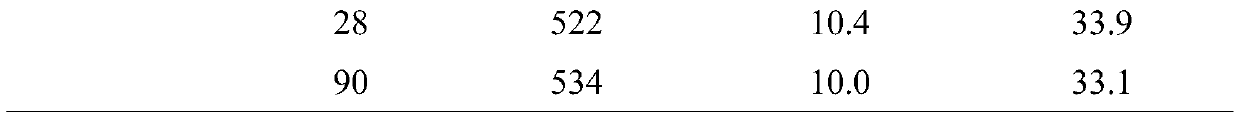

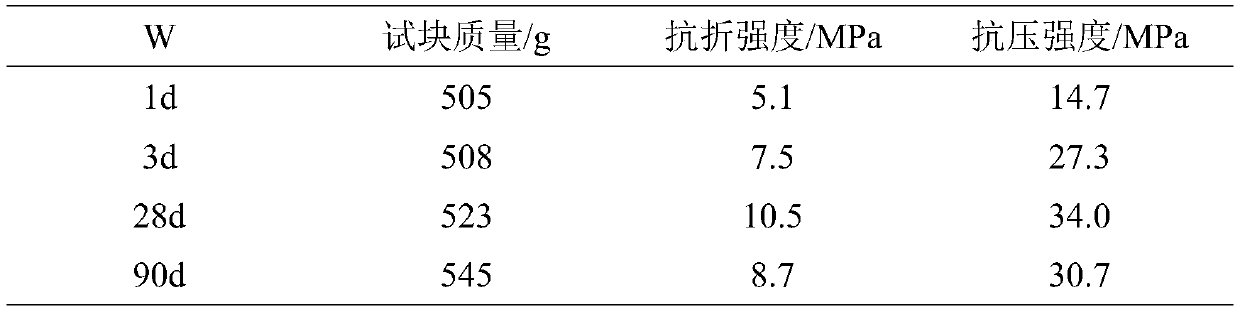

[0031] A highly recognizable red high-strength polymer cement water-resistant mortar. The raw materials used include white cement, metakaolin, latex powder and iron oxide red pigment. The water-binder ratio of the cement mortar is 0.39, and the mortar-sand ratio is 1:1.4. The mass percentages of white cement, metakaolin and latex powder in the material are 89%, 7% and 4% respectively, and the sum of the mass percentages of each component is 100%. The amount of iron oxide red pigment accounts for 1%-7% of the mass of the gelling material. A total of 2 groups were made. Group W used only white cement to make mortar, and Group O made high-resolution red high-strength polymer cement water-resistant mortar mixed with different amounts of iron oxide red pigments.

[0032] The curing method is to put it into a dry curing room for curing for 3 days after demoulding, then move the test block to a standard curing room for curing for 28 days, and finally soak the test block in water for ...

Embodiment 2

[0040] A high-recognition yellow high-strength polymer cement water-resistant mortar. The raw materials used include white cement, metakaolin, latex powder and iron oxide yellow pigment. The water-binder ratio of the cement mortar is 0.39, and the cement-sand ratio is 1:1.4. The mass percentages of white cement, metakaolin and latex powder in the material are 89%, 7% and 4% respectively, and the sum of the mass percentages of each component is 100%. The amount of iron oxide yellow pigment accounts for 5% of the mass of the cementitious material.

[0041] The curing method is to put it into a dry curing room for curing for 3 days after demoulding, then move the test block to a standard curing room for curing for 28 days, and finally soak the test block in water for water resistance test. Use an electronic scale to measure the mass of the test block. According to GB / T17671-1999 "Cement Mortar Strength Test Method", the 3-day, 7-day and 28-day compressive strength of the referen...

Embodiment 3

[0047] A high-recognition green high-strength polymer cement water-resistant mortar. The raw materials used include white cement, metakaolin, latex powder and iron oxide green pigment. The water-binder ratio of the cement mortar is 0.39, and the mortar-sand ratio is 1:1.4. The mass percentages of white cement, metakaolin and latex powder in the material are 89%, 7% and 4% respectively, and the sum of the mass percentages of each component is 100%. The amount of iron oxide green pigment accounts for 5% of the mass of the cementitious material.

[0048] The curing method is to put it into a dry curing room for curing for 3 days after demoulding, then move the test block to a standard curing room for curing for 28 days, and finally soak the test block in water for water resistance test. Use an electronic scale to measure the mass of the test block. According to GB / T17671-1999 "Cement Mortar Strength Test Method", the 3-day, 7-day and 28-day compressive strength of the reference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com