Release agent, release film, composite film and ink-jet printing medium, preparation methods of release agent, release film, composite film and ink-jet printing medium, and application of ink-jet printing medium

A technology of release agent and release film, which is applied in the fields of inkjet printing media and its preparation, composite film, release film, and release agent, and can solve the problems of poor light transmission and inkjet printer recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

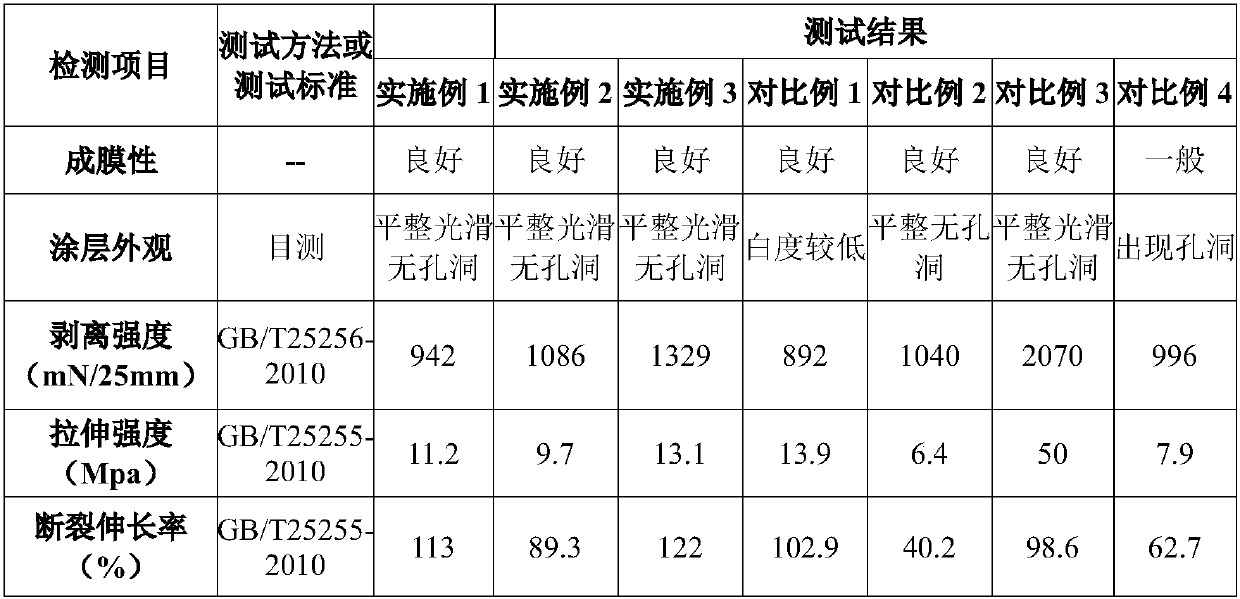

Embodiment 1

[0062] 1, a kind of release agent, it is made up of following components: polyvinyl alcohol 5g, silicon dioxide 1g, rutile type titanium dioxide 4g, aqueous polyurethane 5g, emulsion wax 5g, wetting agent 0.5g and water 70g, wherein, two The particle size of silicon oxide is 3 μm, the particle size of titanium dioxide is 0.34 μm; the solid content of the release agent is 17.2%, and the viscosity is 372 mPa·s.

[0063] This release agent is prepared by the following method:

[0064] (1) dissolving polyvinyl alcohol in deionized water heated to 80° C., after fully dissolving, to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 10%;

[0065] Disperse silicon dioxide in deionized water and disperse it for 0.5h at a speed of 1000r / min in a disperser to obtain a silicon dioxide dispersion with a mass fraction of 10%;

[0066] Disperse titanium dioxide in deionized water, and disperse it for 20 minutes at a speed of 1000 r / min in a disperser to obtain a titani...

Embodiment 2

[0073] 1, a kind of release agent, it is made up of following components: polyvinyl alcohol 6g, silicon dioxide 1.8g, rutile type titanium dioxide 7.2g, aqueous polyurethane 7g, emulsion wax 8g, wetting agent 1g and water 75g, wherein, The particle size of silicon dioxide is 5 μm, and that of titanium dioxide is 0.15 μm; the solid content of the release agent is 20.9%, and the viscosity is 453 mPa·s.

[0074] This release agent is prepared by the following method:

[0075](1) dissolving polyvinyl alcohol in deionized water heated to 80° C., after fully dissolving, to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 10%;

[0076] Disperse silicon dioxide in deionized water, and disperse it for 25 minutes at a speed of 1200r / min in a disperser to obtain a silicon dioxide dispersion with a mass fraction of 15%;

[0077] Disperse titanium dioxide in deionized water and disperse it for 0.5h at a speed of 1200r / min in a disperser to obtain a titanium dioxide ...

Embodiment 3

[0084] 1, a type release agent, it is made up of following components: polyvinyl alcohol 7g, silicon dioxide 1.5g, anatase type titanium dioxide 6g, aqueous polyurethane 10g, emulsion wax 10g, wetting agent 1.5g and water 90.5g, Wherein, the particle size of silicon dioxide is 15 μm, and that of titanium dioxide is 0.5 μm; the solid content of the release agent is 23.7%, and the viscosity is 581 mPa·s.

[0085] This release agent is prepared by the following method:

[0086] (1) dissolving polyvinyl alcohol in deionized water heated to 80° C., after fully dissolving, to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 10%;

[0087] Disperse silicon dioxide in deionized water and disperse for 20 minutes at a speed of 1500 r / min in a disperser to obtain a silicon dioxide dispersion with a mass fraction of 10%;

[0088] Disperse titanium dioxide in deionized water, and disperse it for 0.5h at a speed of 1500r / min in a disperser to obtain a titanium dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com