Preparation method of heavy metal ion remover

A technology of heavy metal ions and removers, applied in the direction of non-metal elements, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high cost of chemical agents, secondary pollution, etc., and achieve economic added value, low cost, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of heavy metal ion remover, comprises the steps:

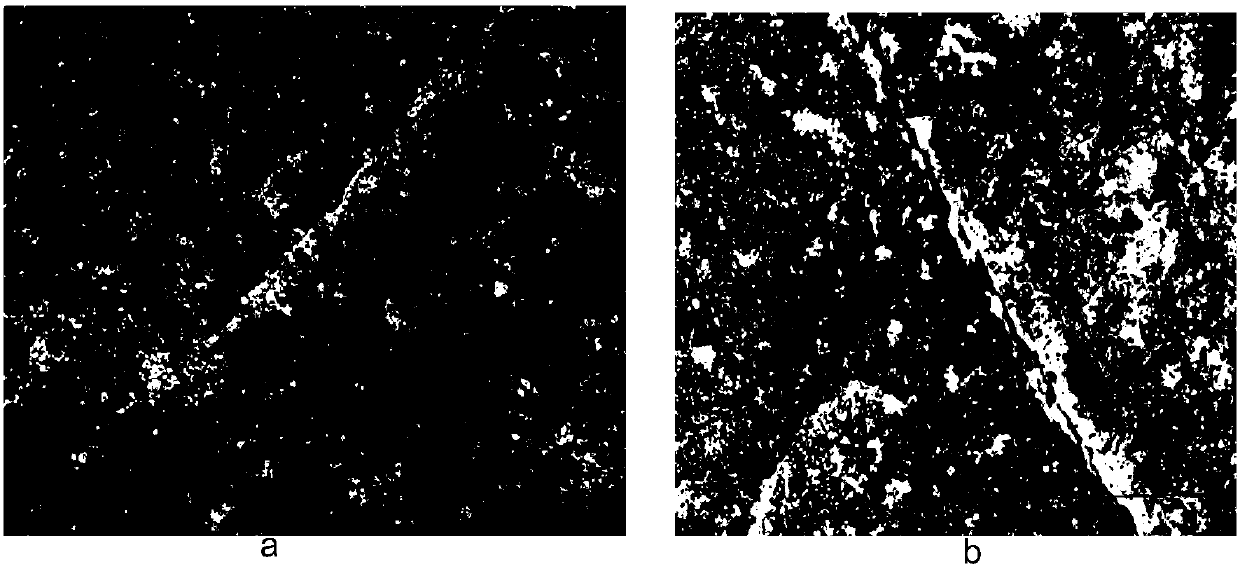

[0031] 1. Select waste concrete from construction waste, and use a small hammer crusher for primary crushing. The waste concrete after primary crushing is put into a resistance furnace for pre-calcination, and it is calcined at 400 ° C for 35 minutes, and there is a situation of interfacial micro-crack penetration. , the ideal separation situation has been reached at this time.

[0032] 2. Vibrate the waste concrete in an electromagnetic vibrating pulverizer to separate coarse aggregate and scrap.

[0033]3. Put the separated crushed material into the ball mill; in order to further increase the specific surface area of hardened cement stone and increase its surface activity, the cement stone separated by sieving is added to the ball mill for ball milling for 20 minutes. During the ball milling process, a compound grinding aid composed of lignosulfonate, ethylene glycol, and ...

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of heavy metal ion remover, comprises the steps:

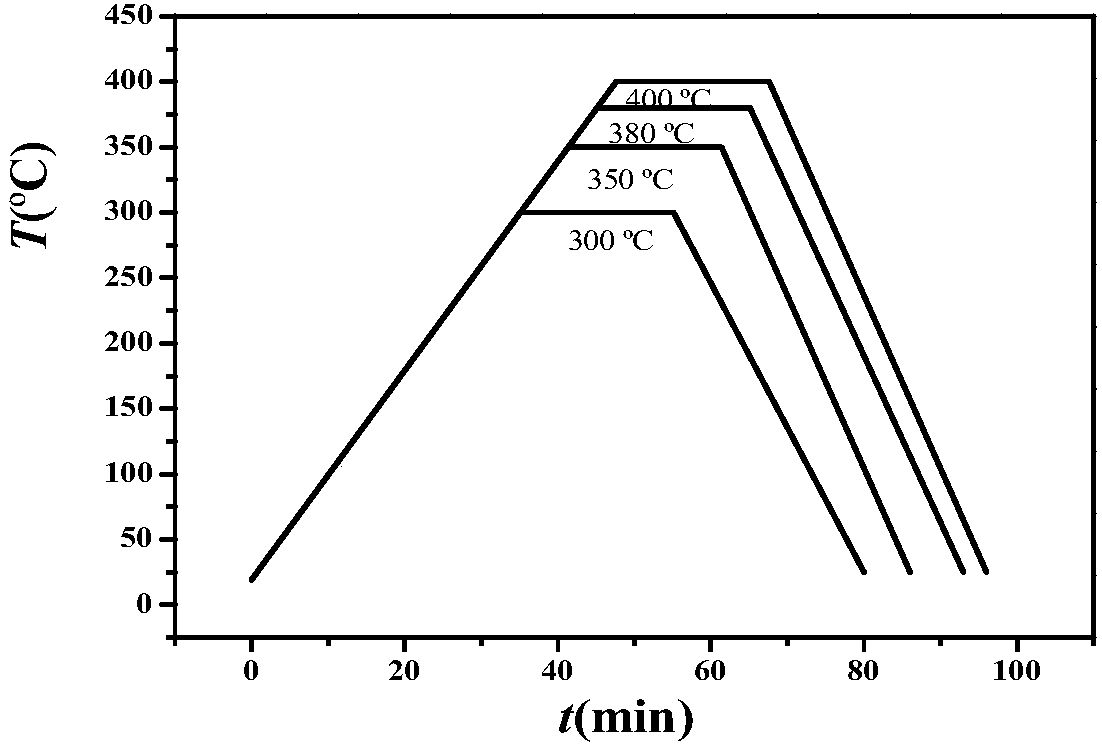

[0036] 1. Select waste concrete from construction waste, and use a small hammer crusher for primary crushing to control the output particle size to ≤10mm. The waste concrete after primary crushing is put into a corundum crucible and put into a box-type resistance furnace in different Pre-burning is carried out under the temperature system, and the pre-burning temperature is controlled at 400°C. After the temperature of the furnace is lowered to 100°C, take it out, transfer it to a desiccator to cool to room temperature, weigh it with an electronic scale, and record the reading.

[0037] 2. Add an appropriate amount of waste concrete each time to crush and separate in the electromagnetic vibrating pulverizer, and control the time of shaking. After shaking and separating, pour it into a square hole sieve to separate the coarse aggregate from the waste cement stone; shake The tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com