Cast steel and preparing method and application of cast steel

A technology of casting steel and molten steel, which is applied in the field of alloy materials, and can solve the problem that the low-temperature toughness of cast steel cannot meet the requirements of use in alpine regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

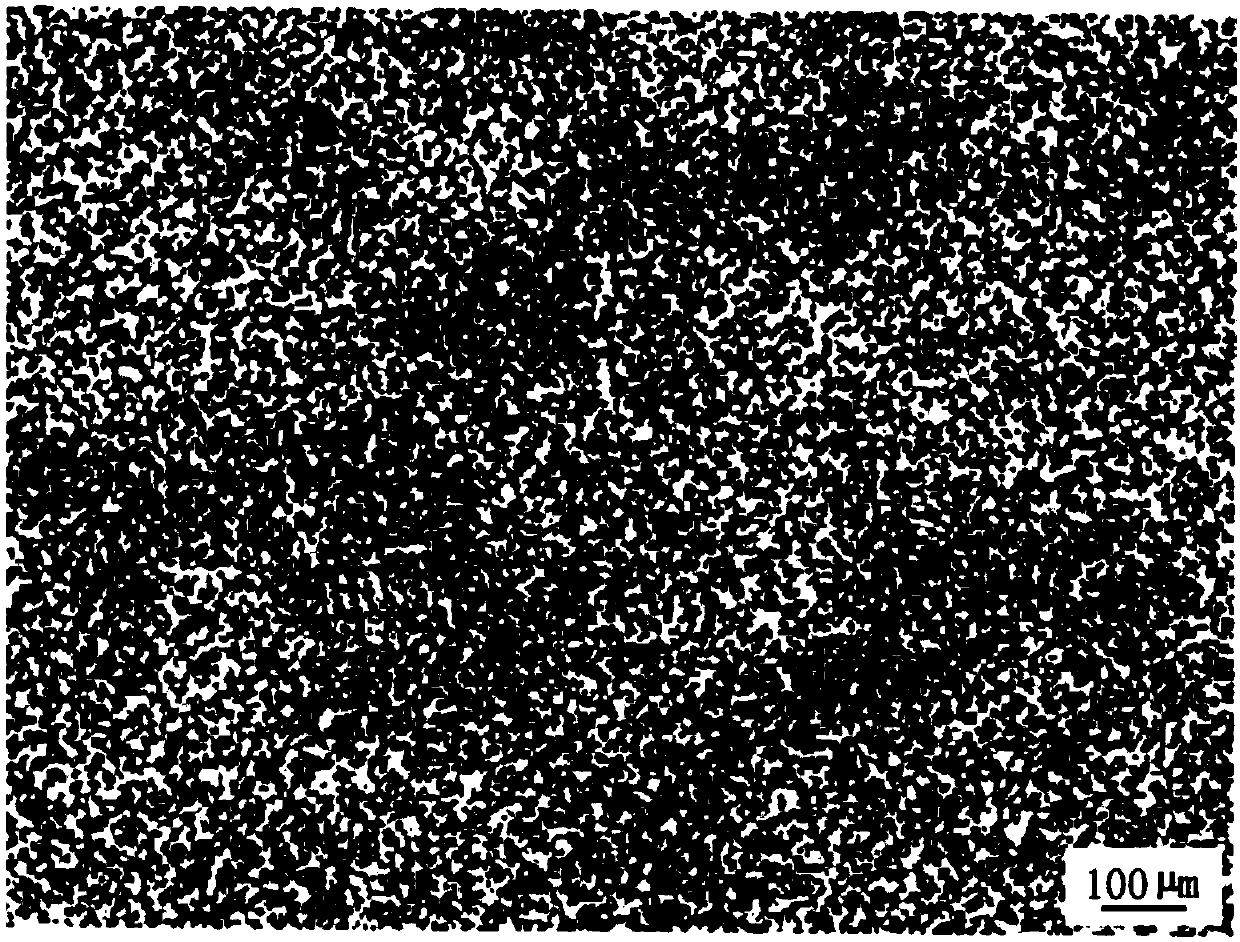

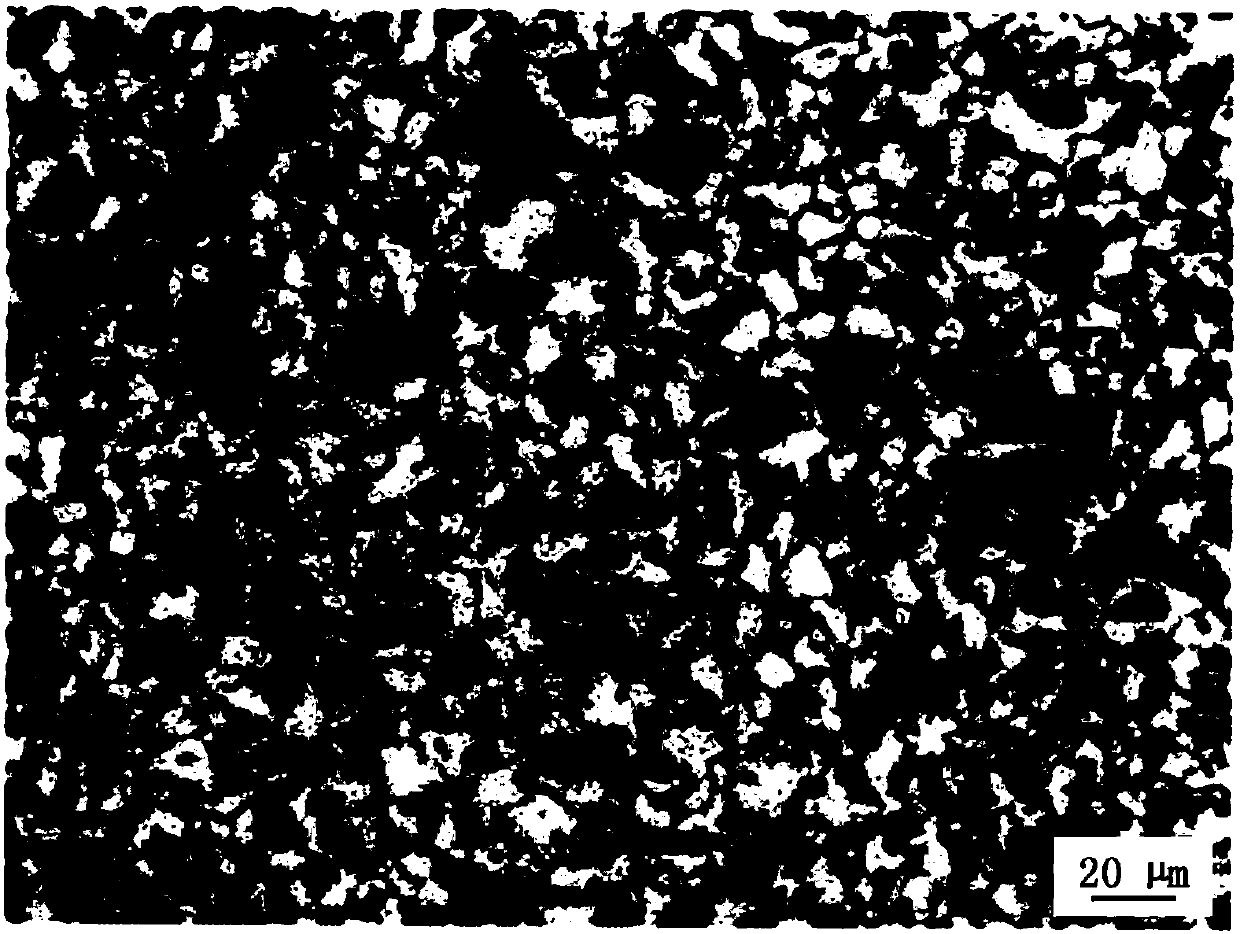

Image

Examples

preparation example Construction

[0039] The tensile strength of the above-mentioned cast steel is greater than or equal to 550MPa, preferably the lower yield strength of the cast steel is greater than or equal to 360MPa, and the preferred elongation of the cast steel is greater than or equal to 20%; the preferred Charpy V-type impact energy absorption of the cast steel at -60°C Greater than or equal to 20J. In another typical embodiment of the present application, a method for preparing cast steel is provided. The preparation method includes: preparing metallic nickel, Fe-Mn alloy, and Fe-Cr alloy according to the composition of any of the above-mentioned cast steel. , Fe-Nb alloy, Fe-Si alloy, carbon powder, iron ore and steel scrap; melting and oxidation treatment of steel scrap and metal nickel to obtain molten iron oxide; reducing molten iron with carbon powder to obtain molten iron; adding Fe-Mn alloy, Fe-Cr alloy, Fe-Nb alloy and Fe-Si alloy into the water to obtain molten steel; and sequentially pourin...

Embodiment 1

[0049] The chemical composition (mass percentage) of the low-alloy medium-strength low-temperature cast steel of this embodiment is: carbon 0.22%, silicon 0.41%, manganese 0.80%, phosphorus 0.015%, sulfur 0.016%, chromium 0.36%, nickel 0.36%, Niobium 0.03%, the balance is iron and other unavoidable impurities, the unavoidable impurity content is less than 0.1%; the total content of phosphorus + sulfur in the cast steel of this embodiment is 0.031%.

[0050] Using scrap steel as raw material, the electric arc furnace redox method is used to make steel. The steps are as follows:

[0051] ① Loading, after cleaning and derusting the discarded carbon steel, put it into the furnace body of the electric arc furnace at the same time as metal nickel.

[0052] The particle size of the added carbon steel block is about 200x200x200mm, and the charge in the furnace body of the electric arc furnace is dense; in addition, the molten carbon ensures that the decarburization amount in the oxida...

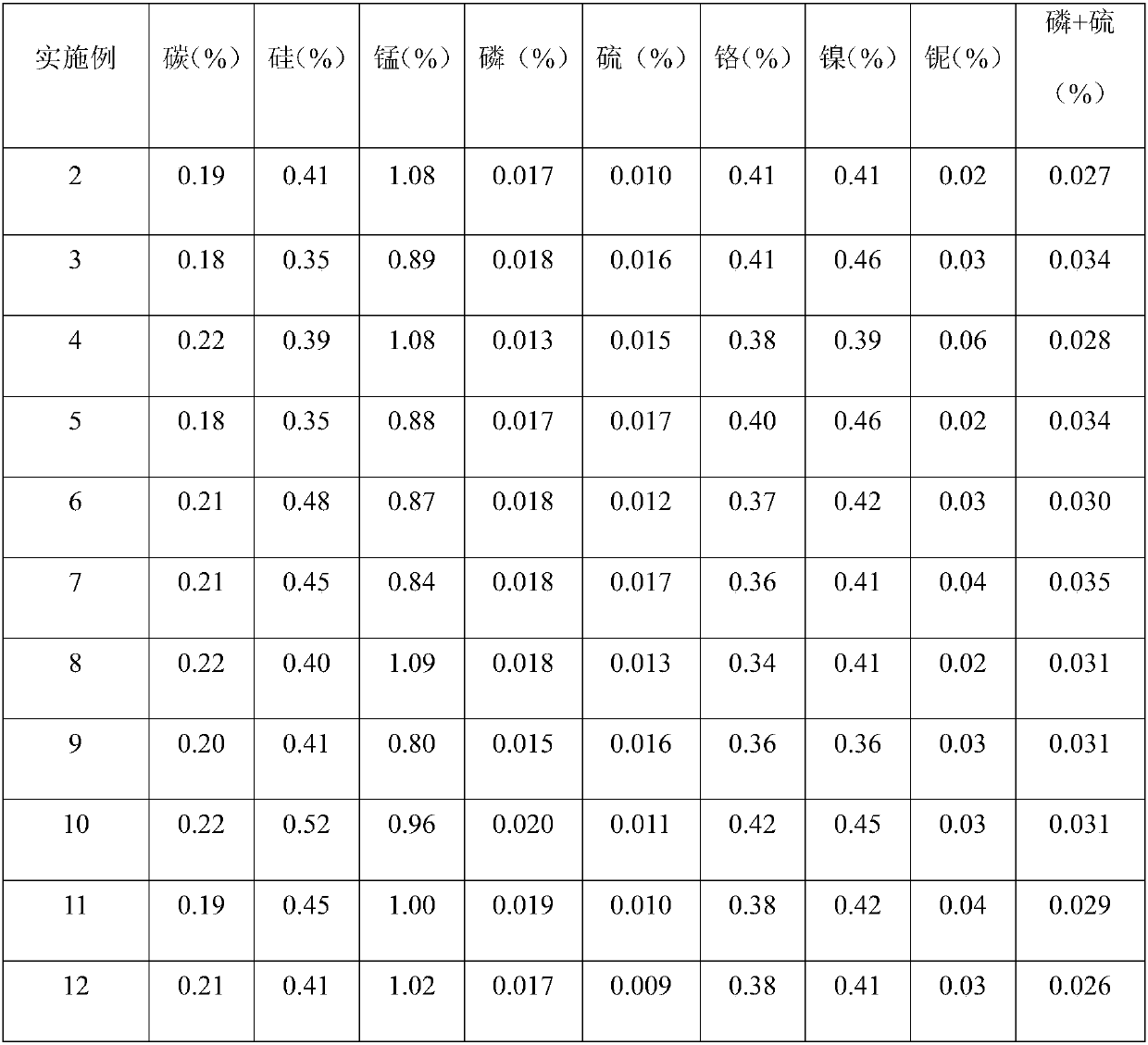

Embodiment 2 to 18

[0064]The chemical compositions of the low-alloy medium-strength low-temperature cast steels of Examples 2 to 18 are shown in Table 1. The content of unavoidable impurities in the low-alloy medium-strength low-temperature cast steels of each example is less than 0.10%. And the smelting method and heat treatment method of the low-alloy cast steel in Embodiment 2 to Embodiment 18 are the same as Embodiment 1.

[0065] Table 1

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com