Carbon nanotube immobilized quaternary ammonium salt magnetic functional material and its preparation method and application

A technology of nano-magnetic materials and immobilized quaternary ammonium salts, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve perchlorate concentration optimization, strong removal capacity, and save treatment time and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

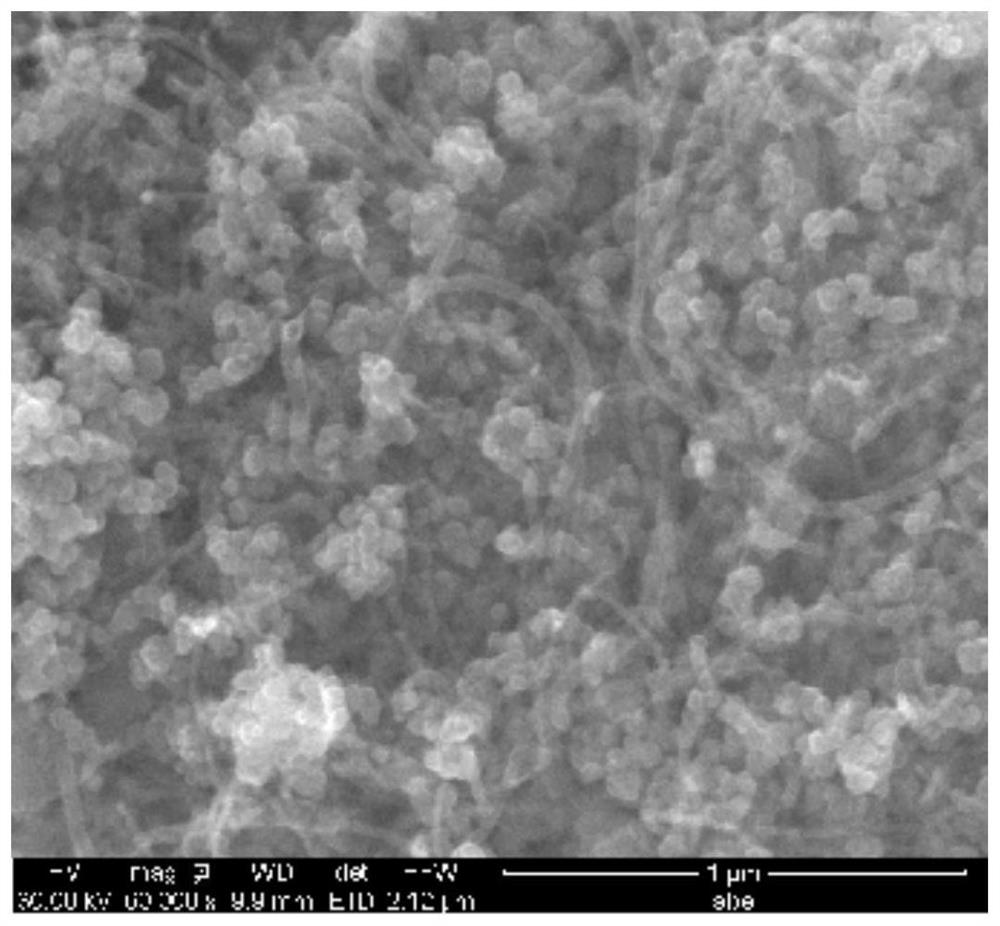

[0025] A preparation method of a carbon nanotube immobilized quaternary ammonium salt magnetic functional material, comprising the steps of:

[0026] (1) Preparation of carbon nanotubes immobilized amino magnetic functional material by solvothermal method, 2.0g FeCl 3 ·6H 2 O was added to 20 mL of ethylene glycol, ultrasonically dispersed until the solution was clear; then 3.0 g of anhydrous sodium acetate was added, followed by 0.5 mL of 10% (V / V) ammonia solution, 20 mL of diethylenetriamine and 50 mg of carboxylated Carbon nanotubes were ultrasonically dispersed for 10 min, and then the above mixed solution was added into a polytetrafluoroethylene autoclave and reacted at 200° C. for 10 h. Cool to room temperature, magnetically separate, wash with ultrapure water several times until the pH is 7.0, then wash with ethanol several times, and vacuum-dry at 60°C for 6 hours to prepare the carbon nanotube-immobilized amino magnetic functional material.

[0027] (2) Prepare carb...

Embodiment 2

[0031] A preparation method of a carbon nanotube immobilized quaternary ammonium salt magnetic functional material, comprising the steps of:

[0032] (1) Preparation of carbon nanotubes immobilized amino magnetic functional material by solvothermal method, 2.0g FeCl 3 ·6H 2 O was added to 20 mL of ethylene glycol, ultrasonically dispersed until the solution was clear; then 3.0 g of anhydrous sodium acetate was added, followed by 2.0 mL of 25% (V / V) ammonia solution, 10 mL of diethylenetriamine and 100 mg of carboxylated carbon The nanotubes were ultrasonically dispersed for 8 minutes, and then the mixed solution was added into a polytetrafluoroethylene autoclave and reacted at 200°C for 12 hours. Cool to room temperature, magnetically separate, wash with ultrapure water several times until the pH is 7.0, then wash with ethanol several times, and vacuum-dry at 30°C for 12 hours to prepare the carbon nanotube-immobilized amino magnetic functional material.

[0033] (2) Prepare...

Embodiment 3

[0036] A preparation method of a carbon nanotube immobilized quaternary ammonium salt magnetic functional material, comprising the steps of:

[0037] (1) Preparation of carbon nanotubes immobilized amino magnetic functional material by solvothermal method, 2.0g FeCl 3 ·6H 2 O was added to 20 mL of ethylene glycol, ultrasonically dispersed until the solution was clear; then 3.0 g of anhydrous sodium acetate was added, followed by 5 mL of 10% (V / V) ammonia solution, 5 mL of diethylenetriamine and 20 mg of carboxylated carbon The nanotubes were ultrasonically dispersed for 5 minutes, and then the above mixed solution was added into a polytetrafluoroethylene autoclave and reacted at 200° C. for 5 hours. Cool to room temperature, magnetically separate, wash with ultrapure water several times until the pH is 7.0, then wash with ethanol several times, and vacuum-dry at 90°C for 8 hours to prepare the carbon nanotube-immobilized amino magnetic functional material.

[0038] (2) Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com