Method for recycling lithium, nickel, cobalt and manganese from waste ternary anode material

A cathode material and recycling method technology, applied in the field of solid waste recycling, can solve the problems of many and complex separation and purification procedures, high cost of reducing agent, low valence metal concentration, etc., and achieve efficient and harmless utilization, good sphericity, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

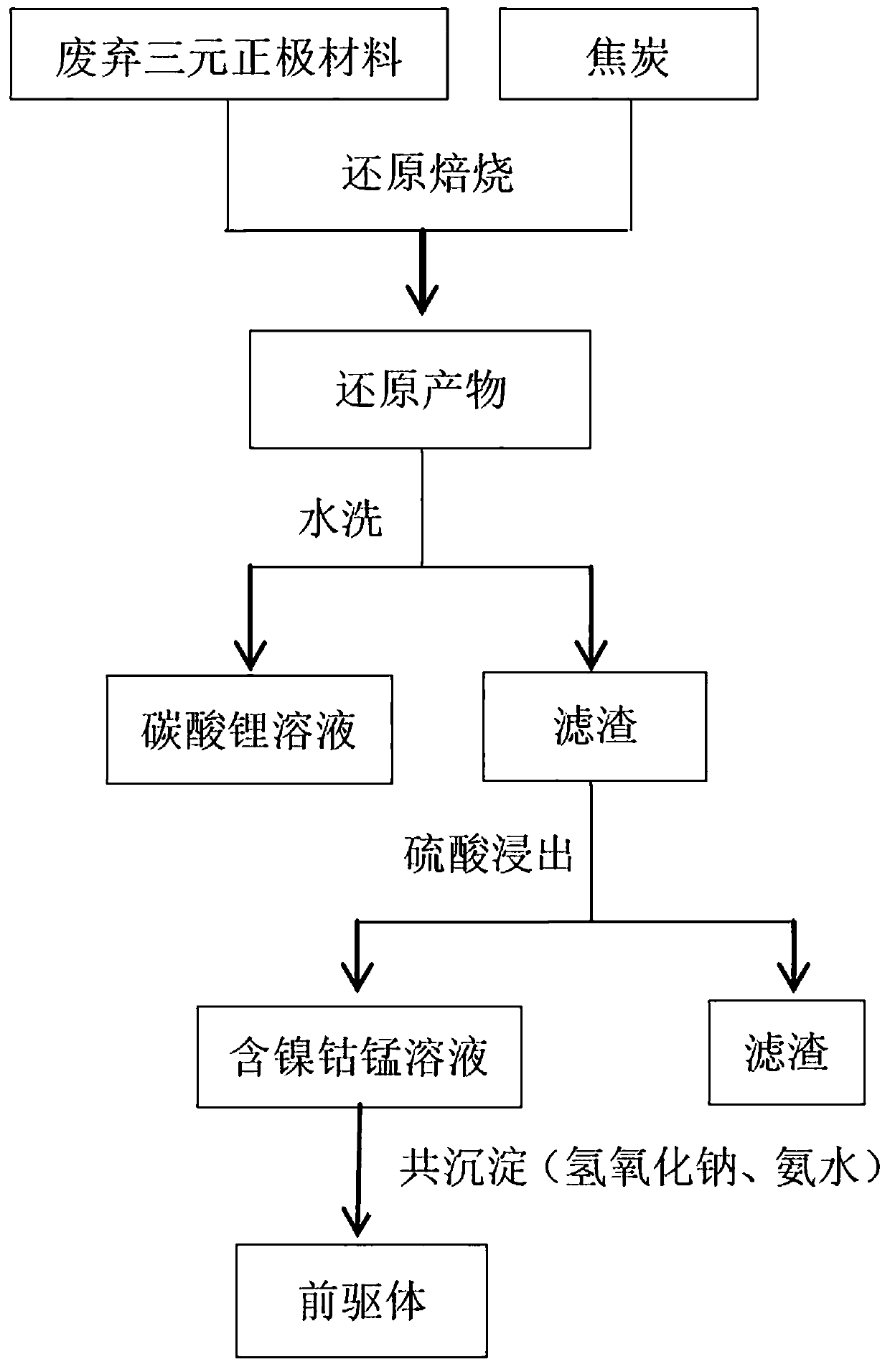

[0046] Process flow chart of the present invention is attached figure 1 shown.

[0047]In this embodiment, a method for recovering lithium, nickel, cobalt, and manganese from waste ternary positive electrode materials comprises the following steps:

[0048] S1. Ball milling and mixing: mill the waste ternary cathode material and coke accounting for 10% of the mass of the waste ternary cathode material in a planetary ball mill at a speed of 200 rpm for 1 hour;

[0049] S2. Reduction roasting: the mixture of the waste ternary cathode material and coke after ball milling is roasted in 99.99% argon atmosphere, the roasting temperature is 600°C, and the roasting time is 2h;

[0050] S3. Water dissolution: add the cooled roasted product into water to dissolve, the dissolution temperature is 30°C, the dissolution time is 4h, the liquid-solid ratio is 100ml / g, and the stirring intensity is 100rpm. After the reaction is completed, the slurry is filtered to obtain the filtrate and Fil...

Embodiment 2

[0055] Experimental raw material, step are with embodiment 1.

[0056] In this embodiment, a method for recovering lithium, nickel, cobalt, and manganese from waste ternary positive electrode materials comprises the following steps:

[0057] S1. Ball milling and mixing: mill the waste ternary cathode material and coke accounting for 5% of the mass of the waste ternary cathode material in a planetary ball mill at a speed of 100rpm for 2h;

[0058] S2. Reduction roasting: the mixture of the ball milled waste ternary cathode material and coke is roasted in 99.99% argon atmosphere, the roasting temperature is 500°C, and the roasting time is 0.5h;

[0059] S3. Water dissolution: add the cooled roasted product into water to dissolve, the dissolution temperature is 25°C, the dissolution time is 2h, the liquid-solid ratio is 50ml / g, and the stirring intensity is 200rpm. After the reaction is completed, the slurry is filtered to obtain the filtrate and Filter residue, sampling analysi...

Embodiment 3

[0064] Experimental raw material, step are with embodiment 1.

[0065] In this embodiment, a method for recovering lithium, nickel, cobalt, and manganese from waste ternary positive electrode materials comprises the following steps:

[0066] S1. Ball mill mixing: mill the waste ternary cathode material and coke accounting for 20% of the mass of the waste ternary cathode material in a planetary ball mill at a speed of 300rpm for 0.5h;

[0067] S2. Reduction roasting: the mixture of the ball milled waste ternary cathode material and coke is roasted in 99.99% argon atmosphere, the roasting temperature is 700°C, and the roasting time is 3h;

[0068] S3. Water dissolution: add the cooled roasted product into water to dissolve, the dissolution temperature is 28°C, the dissolution time is 5h, the liquid-solid ratio is 60ml / g, and the stirring intensity is 500rpm. After the reaction is completed, the slurry is filtered to obtain the filtrate and Filter residue, sampling analysis dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com