Degradable polymer composite material for simulated bait

A composite material and polymer technology, applied in the field of polymer composite materials, can solve the problems of marine organisms and ecological environment hazards, and achieve the effects of strong fish taste, adjustable product softness and hardness, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

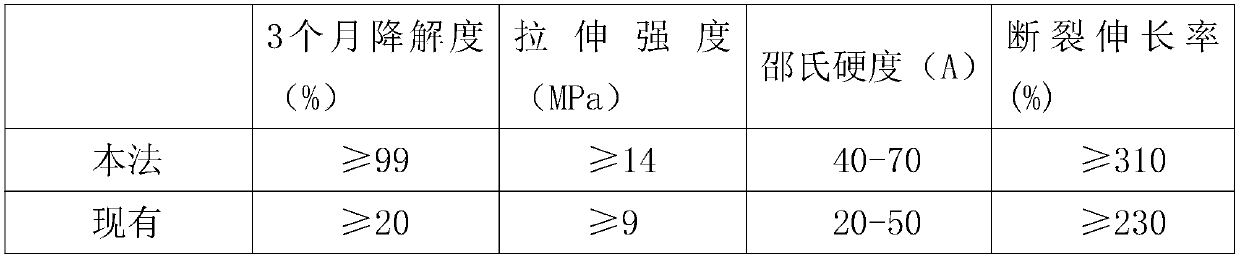

specific Embodiment 1

[0019] A degradable polymer composite material used in artificial fishing baits is prepared by the following steps,

[0020] Step 1: Dehydrate PPC and 1,4-butanediol at 120°C, and then inject it into a twin-screw reaction extruder together with MDI through a metering pump, and make TPU elastomer pellets through chain extension reaction at high temperature ;

[0021] Step 2: Blend and banbury TPU elastomer pellets, PLA and cornstarch in an internal mixer according to a certain mass ratio, and add a certain amount of modification additives and fish-attracting auxiliary materials at the same time, and the mixing time is 10-15 minutes , the mixing temperature is kept at 120-130°C;

[0022] Step 3: Put the homogeneously mixed material after banburying in step 2 into the hopper of a twin-screw extruder for melt extrusion, strand drawing, and pelletizing. Cool and dry to obtain modified polyurethane elastomer particles, which are ready for use;

[0023] Step 4: Use the screw of th...

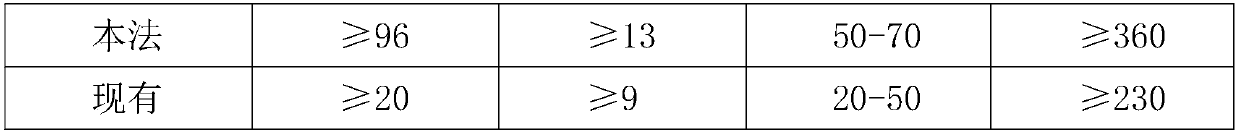

specific Embodiment 2

[0032] A degradable polymer composite material used in artificial fishing baits is prepared by the following steps,

[0033] Step 1: Dehydrate PPC and 1,4-butanediol at 120°C, and then inject it into a twin-screw reaction extruder together with MDI through a metering pump, and make TPU elastomer pellets through chain extension reaction at high temperature ;

[0034] Step 2: Blend and banbury TPU elastomer pellets, PLA and cornstarch in an internal mixer according to a certain mass ratio, and add a certain amount of modification additives and fish-attracting auxiliary materials at the same time, and the mixing time is 10-15 minutes , the mixing temperature is kept at 120-130°C;

[0035] Step 3: Put the homogeneously mixed material after banburying in step 2 into the hopper of a twin-screw extruder for melt extrusion, strand drawing, and pelletizing. Cool and dry to obtain modified polyurethane elastomer particles, which are ready for use;

[0036] Step 4: Use the screw of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com