Preparation method for carbon negative electrode material of sodium ion battery

A carbon anode material, sodium ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the limitation of anode material selection, and achieve the effect of reducing production and storage costs, low cost, and conducive to transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation method of this sodium ion battery carbon negative electrode material, concrete operation is as follows:

[0023] (1) First, wash and dry the collected cherry blossom petals to obtain product A;

[0024] (2) The product A obtained in step (1) was placed in a tube furnace and calcined in an Ar atmosphere at a temperature of 1000 °C for 1 h to obtain product B;

[0025] (3) The product B obtained in step (2) was taken out and placed in a 3mol / L HCl solution, and soaked at 20°C for 6 hours to obtain product C;

[0026] (4) The product C obtained in step (3) is fully washed with deionized water, and dried to obtain a carbon negative electrode material for a sodium ion battery.

[0027] Material Characterization

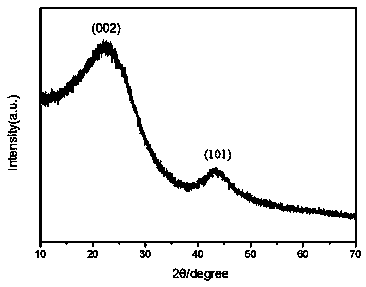

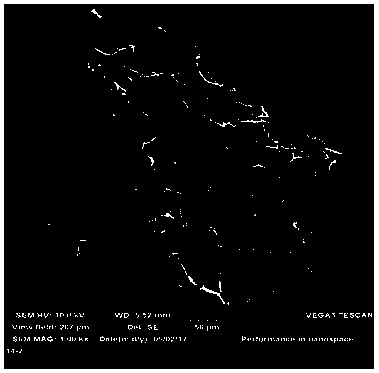

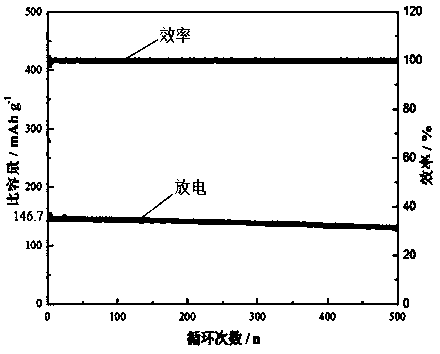

[0028] The crystal structure of carbon anode materials for sodium-ion batteries was analyzed by X-ray powder diffractometer (using Rigaku miniFlex600 diffractometer with Cu Kα ray source), as figure 1 As shown, it can be seen from th...

Embodiment 2

[0032] Embodiment 2: the preparation method of this sodium ion battery carbon negative electrode material, concrete operation is as follows:

[0033] (1) First, wash and dry the collected cherry blossom petals to obtain product A;

[0034] (2) The product A obtained in step (1) was placed in a tube furnace and calcined at 600 °C for 6 h in an Ar atmosphere to obtain product B;

[0035] (3) The product B obtained in step (2) was taken out and placed in a 2mol / L HCl solution and soaked for 12 h at a temperature of 25°C to obtain product C;

[0036] (4) The product C obtained in step (3) is fully washed with deionized water, and dried to obtain a carbon negative electrode material for a sodium ion battery.

Embodiment 3

[0037] Embodiment 3: the preparation method of this sodium ion battery carbon negative electrode material, concrete operation is as follows:

[0038] (1) First, wash and dry the collected cherry blossom petals to obtain product A;

[0039] (2) Place the product A obtained in step (1) in a tube furnace, under N 2 In the atmosphere, calcined at a temperature of 800 °C for 5 h to obtain product B;

[0040] (3) The product B obtained in step (2) was taken out and placed in a 1mol / L HCl solution for 9 h at a temperature of 23°C to obtain product C;

[0041] (4) The product C obtained in step (3) is fully washed with deionized water, and dried to obtain a carbon negative electrode material for a sodium ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com