Electrolytic preparation method for composite phosphating film

A phosphating film and electrode technology, which is applied in the field of electrolytic preparation of composite phosphating films, can solve the problems of destroying the mechanical properties of metal substrates, rising production costs, and severe hydrogen evolution reaction, and achieves excellent tensile ductility, easy management, and high performance. The effect of high membrane efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0016] The embodiment of the present invention discloses an electrolytic preparation method of a composite phosphating film. Through a specific current density application method, the composite phosphating film treatment solution treats a steel workpiece and electrolyzes to form a layer of rare earth cerium element-doped organic film on its surface. Phosphorus-inorganic phosphating composite protective layer.

[0017] The content of each component of the composition raw material of described composite phosphating film treatment liquid is: phosphoric acid 18g / L, nitric acid 7g / L, zinc oxide 8.5g / L, nickel sulfate 3g / L, sodium phytate 3.2g / L, Sodium hexafluorophosphate 0.3g / L, succinic acid 0.25g / L, ammonium phosphomolybdate 0.12g / L, hydroxylamine sulfate 0.6g / L, cerous nitrate 0.01g / L, hydrogen peroxide 0.01g / L, solvent is water.

[0018] The preparation method of the composite phosphating film treatment solution is: add half of the total amount of water required, phosphoric ac...

Embodiment 1

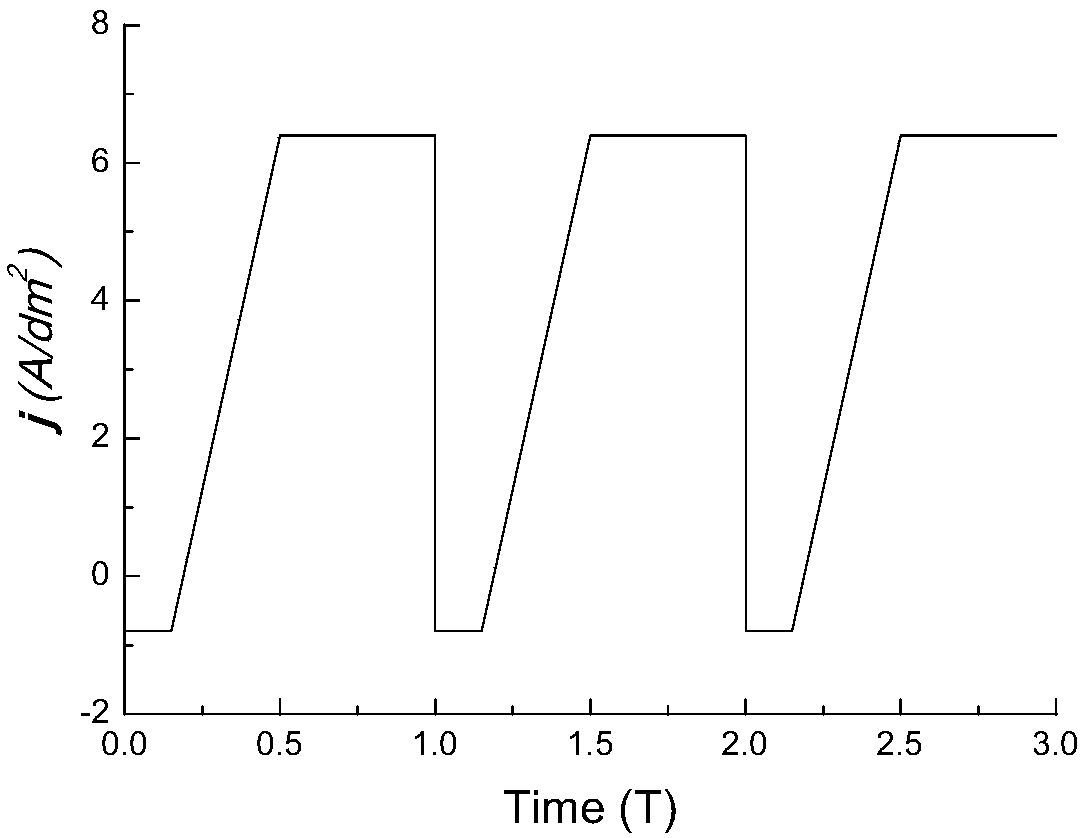

[0020] Embodiment 1: The preparation parameters of composite phosphating film electrolytic treatment are: total acidity 75.5pt, free acid 7.8pt, pH2.7, treatment temperature is 55 ℃, with titanium ruthenium plated plate as anode material, with spring wire rod as cathode, like figure 1 As shown, the abscissa is the processing time (with the period T as the unit, T=5s), and the ordinate is the current density. The current application method during the carrier electrolysis treatment is: give a low current density-0.8A / dm 2 And maintain it for 0.75s, then linearly increase to a high current density of 6.4A / dm through 1.75s 2 , and maintain for 2s to the end of 1 cycle. Repeat 3 cycles, that is, after 15 seconds of treatment, a layer of gray electrolytic composite phosphating film is obtained on the surface of the workpiece, and then transferred to the cold forging manufacturing process. figure 2 The scanning electron micrograph (x2000) of the corresponding electrolytic phosphat...

Embodiment 2

[0021] Example 2: Composite phosphating film electrolytic treatment preparation parameters are: total acidity 68.2pt, free acid 8.0pt, pH2.5, treatment temperature is 25°C, titanium ruthenium plated plate is used as anode material, steel wire is used as cathode, carrier electrolysis The current application method during treatment is: give a low current density -0.2A / dm 2 And maintain for 3s, then linearly increase to a high current density of 7.2A / dm through 7.5s 2 , and maintain for 4.5s to the end of 1 cycle. Repeat 2 cycles, that is, after 30 seconds of treatment, a layer of gray electrolytic composite phosphating film is obtained on the surface of the workpiece, and then it is transferred to the saponification drawing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com