A kind of negative temperature coefficient thermistor with nanoparticle film and its preparation method

A technology of negative temperature coefficient and thermistor, which is applied in the direction of resistors with negative temperature coefficient, resistance terminals/electrodes, etc., which can solve the problem of weak electrode protection, weak adhesion between glass and electrode layers, and influence on the performance of substrate components, etc. problems, to achieve the effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

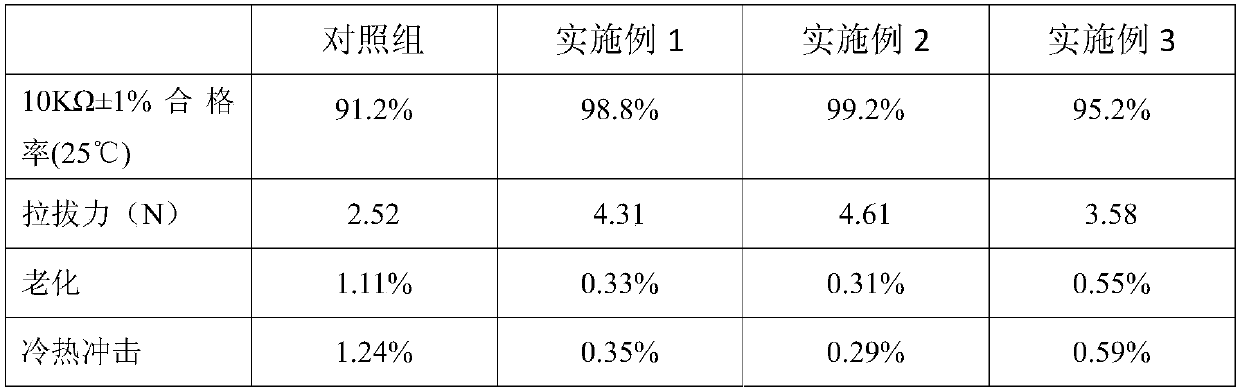

Examples

Embodiment 1

[0024] A preparation method of a negative temperature coefficient thermistor with a nanoparticle film, comprising the steps of:

[0025] (1) Soak the ceramic substrate with 5% hydrofluoric acid for 5 minutes, then ultrasonically clean it with acetone, alcohol and deionized water for 10 minutes, clean it with nitrogen, and seal it for use;

[0026] (2) Use pre-sputtering to remove the oxide layer on the surface of the ceramic substrate, and then coat a layer of metallic nickel to form a transition layer, wherein the thickness of the nickel layer is 0.2 μm;

[0027] (3) A layer of metal copper is sputtered on the transition layer by magnetron sputtering to form a copper electrode layer, and the thickness of the copper electrode layer is 2 μm;

[0028] (4) After the copper electrode in step (3) is connected to the pin, a layer of nano-aluminum film is sputtered on the surface of the copper electrode layer by magnetron sputtering. The substrate temperature used for sputtering the ...

Embodiment 2

[0031] A preparation method of a negative temperature coefficient thermistor with a nanoparticle film, comprising the steps of:

[0032] (1) Soak the ceramic substrate with 5% hydrofluoric acid for 5 minutes, then ultrasonically clean it with acetone, alcohol and deionized water for 10 minutes, clean it with nitrogen, and seal it for use;

[0033] (2) Pre-sputtering is used to remove the oxide layer on the surface of the ceramic substrate, and then a layer of metallic nickel is coated to form a transition layer, and the thickness of the nickel layer is 0.5 μm;

[0034] (3) A layer of metal copper is sputtered on the transition layer by magnetron sputtering to form a copper electrode layer, and the thickness of the copper electrode layer is 1 μm;

[0035] (4) After the copper electrode in step (3) is connected to the pins, a layer of nano-aluminum film is sputtered on the surface of the copper electrode layer by magnetron sputtering, wherein the substrate temperature used for t...

Embodiment 3

[0038] A preparation method of a negative temperature coefficient thermistor with a nanoparticle film, comprising the steps of:

[0039] (1) Soak the ceramic substrate with 5% hydrofluoric acid for 5 minutes, then ultrasonically clean it with acetone, alcohol and deionized water for 10 minutes, clean it with nitrogen, and seal it for use;

[0040] (2) A layer of metal copper is sputtered on the surface of the ceramic substrate by magnetron sputtering to form a copper electrode layer, and the thickness of the copper electrode layer is 1 μm;

[0041] (3) After the copper electrode in step (2) is connected to the pin, a layer of nano-aluminum film is sputtered on the surface of the copper electrode layer by magnetron sputtering. The substrate temperature used for sputtering the nano-aluminum film is 100°C. The air pressure used is 2Pa,

[0042] Sintering in a weak oxidizing atmosphere to form a nano-alumina film with a thickness of 200nm.

[0043] In the present embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com