Preparation method of high reflection solar cell back plate film

A solar cell, high-reflection technology, applied in chemical instruments and methods, film/sheet adhesives, circuits, etc., can solve the problems of inability to increase the power of components, complicated production processes, and prolonged production cycles, and achieve improved performance. Overall water blocking performance, improved reflectivity, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

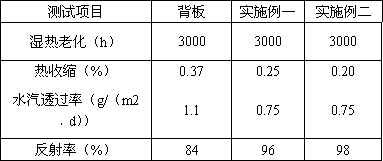

Examples

specific Embodiment 1

[0017] A method for preparing a highly reflective solar cell backplane film disclosed by the present invention specifically includes the following steps:

[0018] 70 parts of PP resin, 20 parts of white POE masterbatch, 5 parts of titanium dioxide and 6 parts of talcum powder mixed filler (the ratio of titanium dioxide and talc powder is 5:1), 0.5 parts of triethyl phosphate, 0.5 parts of antioxidant 1010, 2 1 part of polycarbodiimide UN-03, 2 parts of 2-(4,6-diphenyl-1,3,5-triazin-2-yl-)-5-hexyloxyphenol mixed, extruded by twin-screw Extrusion granulation, the temperature in zone I of the twin-screw extruder is 65°C, the temperature in zone II is 165°C, the temperature in zone III is 185°C, the temperature in zone IV is 195°C, the temperature in zone V is 210°C, and the temperature of the head is 200°C. Stay in the twin-screw for 3.5 minutes to obtain the adhesion layer masterbatch;

[0019] Take 50 parts of PET particles with a molecular weight of 47000 and dry them in a va...

specific Embodiment 2

[0022] 65 parts of PE resin, 30 parts of white POE masterbatch, 5 parts of titanium dioxide and 6 talcum powder mixed filler (the ratio of titanium dioxide and talc powder is 5:1), 0.5 part of triethyl phosphate, 0.5 part of antioxidant 1010, 2 parts Polycarbodiimide UN-03, 2 parts of 2-(4,6-diphenyl-1,3,5-triazin-2-yl-)-5-hexyloxyphenol mixed, extruded by twin-screw Machine extrusion granulation, in the twin-screw extruder, the temperature in zone I is 65°C, the temperature in zone II is 165°C, the temperature in zone III is 185°C, the temperature in zone IV is 195°C, the temperature in zone V is 210°C, and the temperature of the head is 200°C. Stay in the twin-screw for 3.5 min to obtain the adhesion layer masterbatch;

[0023] Take 70 parts of PET particles with a molecular weight of 47000 and dry them in a vacuum drum at 80°C for 3 hours, add 0.1 parts of triethyl phosphate, 0.1 parts of pentaerythritol tetrakis (bis-T-butyl hydroxyhydrocinnamic acid) ester, 0.1 parts Ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com