Scribing machine booster with illuminating function

A technology of marking machine and booster, applied in the directions of brakes, roads, and road repairs, etc., can solve the problems of inconvenient transfer and use of construction sites, unstable construction quality of marking lines, complex structure layout, etc. Ease of control and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

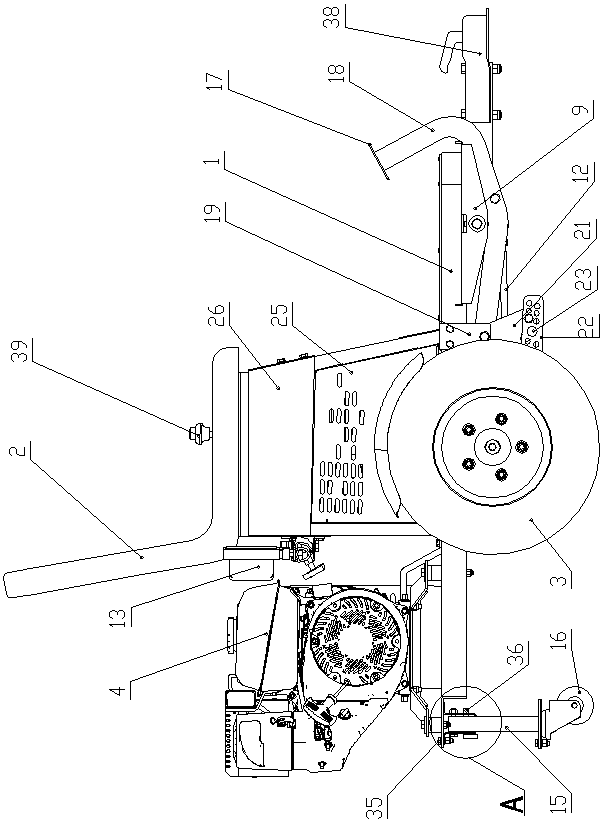

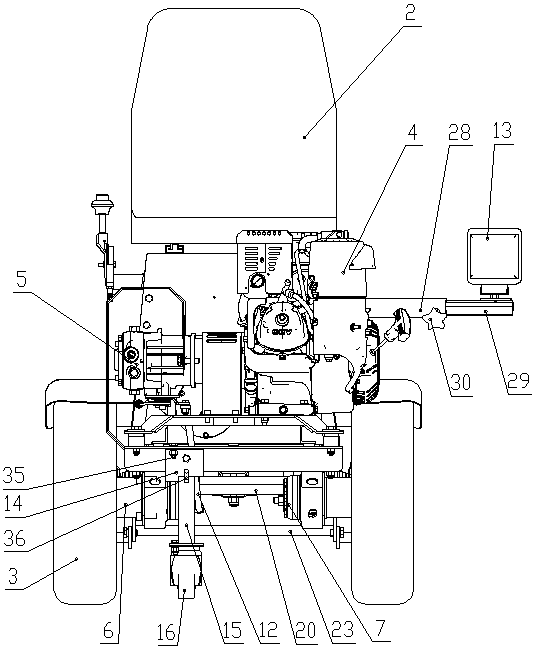

[0032]Such as Figure 1 to Figure 5 shown in figure 1 The right side of the right side is the forward direction of the present invention. The marking machine booster with lighting function of the present invention includes a vehicle frame 1, a seat 2, two driving wheels 3, a power transmission system, a braking system and a lighting system. The front end of the frame 1 is detachably connected to the marking machine, the seat 2 is fixedly installed above the middle of the frame 1, and the two driving wheels 3 are respectively located on the left and right sides of the middle of the frame 1;

[0033] The power transmission system includes engine 4, hydraulic pump 5, hydraulic oil tank, reversing transmission mechanism, left wheel side motor 6 and right wheel side motor 7, engine 4, hydraulic pump 5 and hydraulic oil tank are all fixedly installed on the vehicle frame 1, hydraulic oil tank Blocked, not shown in the figure, the left wheel side motor 6 and the right wheel side mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com