SiC hollow sphere and preparation method of same

A technology of hollow spheres and template spheres, which is applied in the field of lightweight and high-strength SiC hollow spheres and its preparation, can solve the problems of SiC material sintering difficulty, small size and high cost of SiC hollow spheres, and achieve rapid batch production and uniform size , Enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

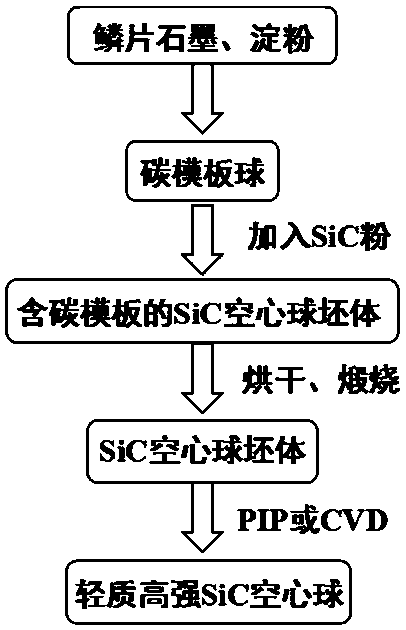

[0032] A method for preparing the lightweight and high-strength SiC hollow ball of the present invention, such as figure 1 As shown, including the following steps:

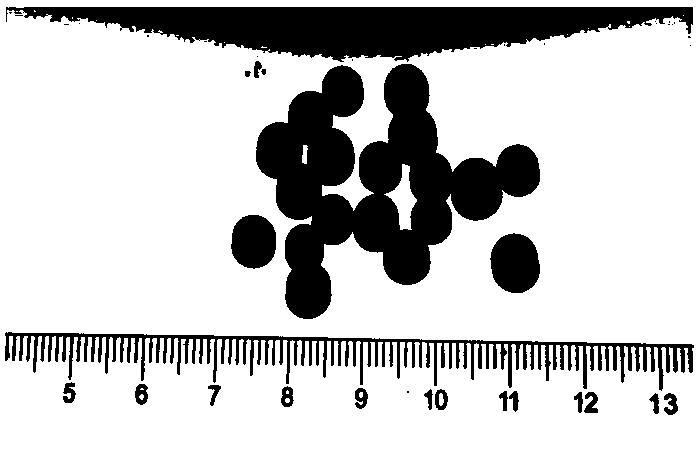

[0033] (1) Mix the flake graphite, starch and water in a mass ratio of 2:3:5, and then squeeze in a pellet machine to obtain a carbon template ball with a diameter of 3mm. Put 20g of the carbon template ball into In the rolling ball machine, add 20g SiC (α-SiC) ceramic powder, roll the carbon template ball for 30 minutes at a speed of 300r / min, and then add 5g SiC (α-SiC) ceramic powder, continue rolling for 30 minutes to form a surface coating SiC powder, SiC hollow sphere body with carbon-containing template balls inside;

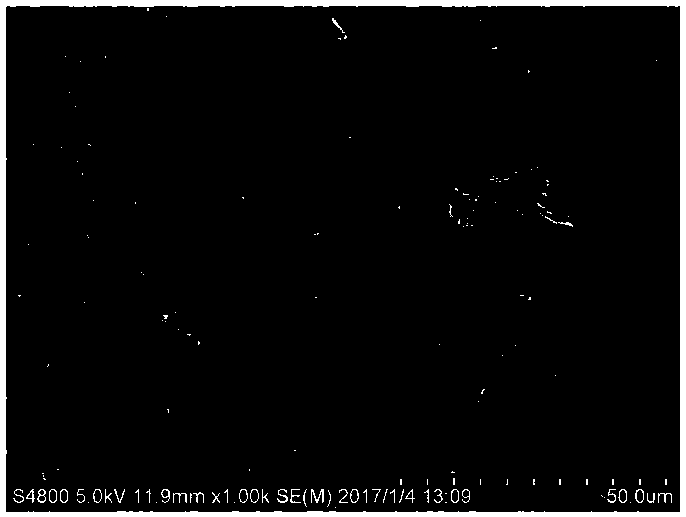

[0034] (2) Dry the SiC hollow sphere body in an oven at 90°C for 12 hours, then put the dried body into a muffle furnace for calcination, and raise the temperature to 400°C at a heating rate of 8°C / min. The temperature is increased to 800°C at a heating rate of 2°C / min, the temperature is kept fo...

Embodiment 2

[0050] A method for preparing the lightweight and high-strength SiC hollow ball of the present invention, such as figure 1 As shown, including the following steps:

[0051] (1) Mix the flake graphite, starch and water in a mass ratio of 2:3:5, and then squeeze it in a pellet machine to obtain a carbon template ball with a diameter of 3mm. Put 20g of the carbon template ball into it. In the rolling ball machine, add 30g SiC (α-SiC) ceramic powder, roll the carbon template ball for 30 minutes at a speed of 300r / min, then add 10g SiC (α-SiC) ceramic powder, and continue rolling for 30 minutes to form a surface coating SiC powder, SiC hollow sphere body with carbon-containing template balls inside;

[0052] (2) Dry the SiC hollow sphere body in an oven at 90°C for 12 hours, then put the dried body into a muffle furnace for calcination, and raise the temperature to 400°C at a heating rate of 8°C / min. The temperature is increased to 800°C at a heating rate of 2°C / min, the temperature is...

Embodiment 3

[0056] A method for preparing the lightweight and high-strength SiC hollow ball of the present invention, such as figure 1 As shown, including the following steps:

[0057] (1) Mix the flake graphite, starch and water in a mass ratio of 2:3:5, and then squeeze in a pellet machine to obtain a carbon template ball with a diameter of 3mm. Put 20g of the carbon template ball into In the rolling ball machine, add 20g SiC (α-SiC) ceramic powder, roll the carbon template ball for 30 minutes at a speed of 300r / min, and then add 5g SiC (α-SiC) ceramic powder, continue rolling for 30 minutes, forming a surface coating SiC powder, SiC hollow sphere body with carbon-containing template balls inside;

[0058] (2) Dry the SiC hollow sphere body in an oven at 90°C for 12 hours, then put the dried body into a muffle furnace for calcination, and raise the temperature to 400°C at a heating rate of 8°C / min. The temperature is increased to 800°C at a heating rate of 2°C / min, the temperature is kept f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com