Preparation and application method of an ozone-enhanced catalytic material

A catalytic material and ozone technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as loss of titanium dioxide, impact on continuous operation, fast reaction speed, etc. , to achieve the effect of increased carrier strength, significant carrier strength and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

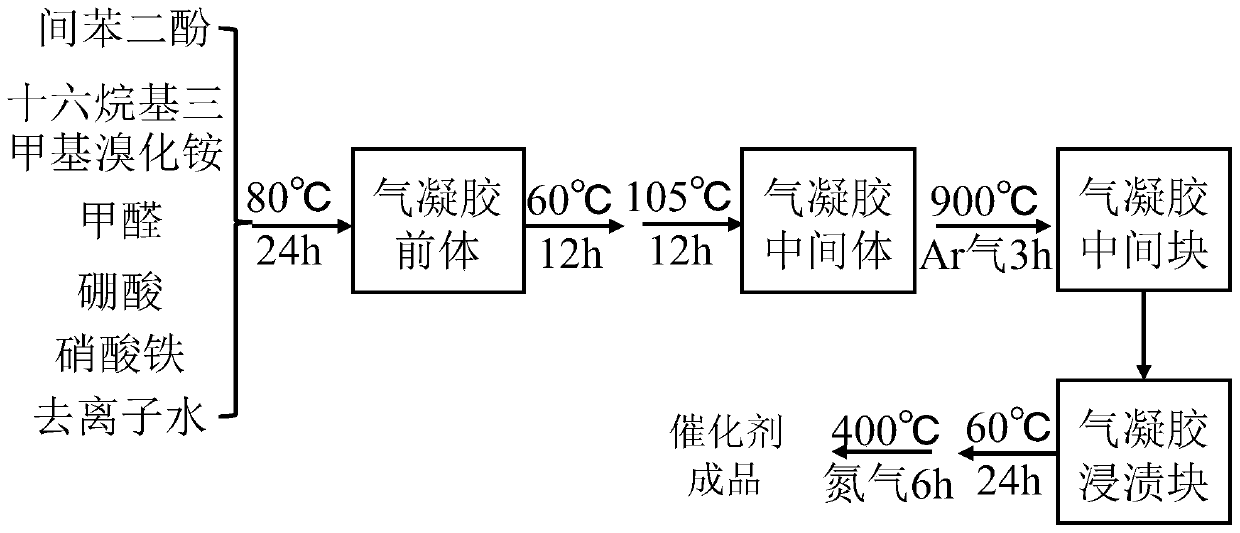

[0035] 2. Preparation method of iron-loaded mesoporous carbon airgel intermediate

[0036] The iron-loaded mesoporous carbon airgel precursor was aged at 60°C and 105°C for 12 hours, respectively, and dehydrated to obtain the iron-loaded mesoporous carbon airgel intermediate;

[0037] 3. Preparation method of iron-loaded mesoporous carbon aerogel

[0038] Keep the prepared iron-loaded mesoporous carbon aerogel intermediate in a high-temperature furnace under an argon atmosphere at 900°C for 3 to 4 hours, take it out after cooling, and prepare the iron-loaded mesoporous carbon aerogel;

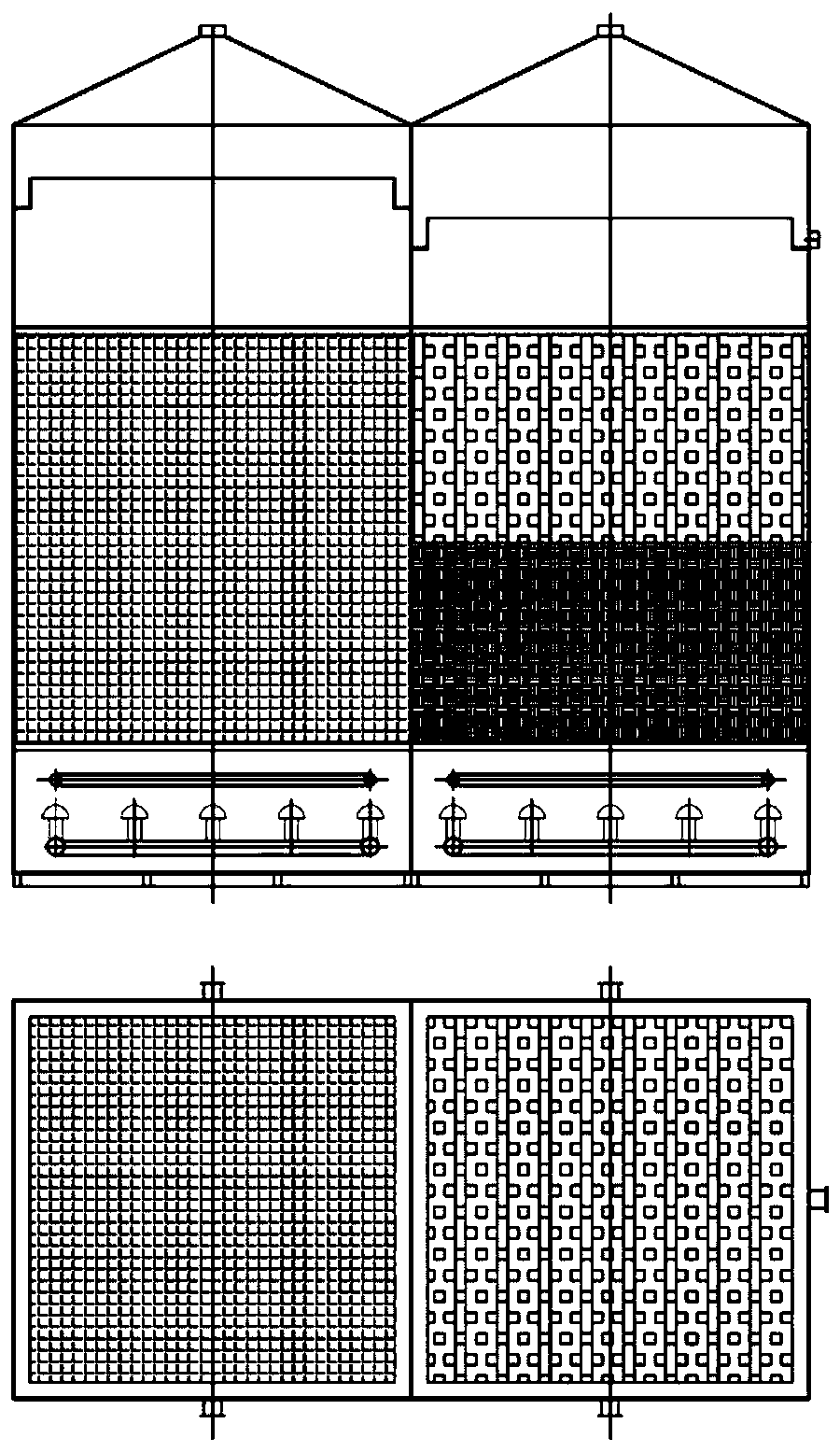

[0039] Plastic or stainless steel is used as the mold, and the shape of the cavity inside the mold can be ring-shaped, cubic or fan-shaped, and the iron-loaded mesoporous carbon airgel precursor prepared in step (1) is poured into it, and the operation of step (2) is carried out, and the The mold of the gel precursor was placed in an oven and aged at 60°C and 105°C for 12 hours respectively. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com