Sulfur-free dried persimmons and making method thereof

A production method and a technology for persimmon cakes are applied in the fields of food preservation, preservation of fruits/vegetables by radiation/electric treatment, preservation of fruits and vegetables, etc., which can solve the problems such as the difficulty of ensuring food safety in the sulfur fumigation process, the complicated operation of the processing method, and the difficult quality control. , to achieve the effect of safety and environmental protection, good taste and integrity of the production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

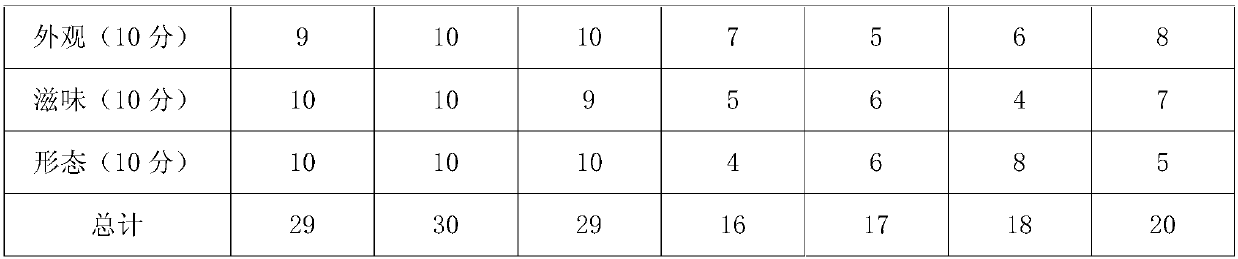

Embodiment 1

[0029] A kind of preparation method of sulfur-free persimmon, comprises the following steps:

[0030] (1) Choose ripe and plump persimmons with hard flesh and no mechanical damage or wormholes as raw materials. Put the persimmons into an ethanol solution with a volume concentration of 70% and soak them for 3 minutes under 60KHz ultrasonic conditions. After taking them out, immerse the persimmons in a 38°C After soaking in water for 7 hours, remove the persimmon peel for later use;

[0031] (2) Put the peeled persimmons described in step (1) into a drum punching machine to puncture holes, then put them into a vacuum microwave drier to dry until the water content of the persimmons is within 50%; wherein, The microwave power density of described drying is 0.4w / g, and vacuum degree is 60KPa;

[0032] (3) Put the dried persimmons in step (2) into a softener to soak for 20 minutes under vacuum conditions, and then soak for 4 hours under normal pressure; wherein, the vacuum degree o...

Embodiment 2

[0041] A kind of preparation method of sulfur-free persimmon, comprises the following steps:

[0042] (1) Choose ripe and plump persimmons with hard flesh and no mechanical damage or wormholes as raw materials. Put the persimmons in an ethanol solution with a volume concentration of 72% and soak them for 5 minutes under 80KHz ultrasonic conditions. After taking them out, immerse the persimmons in a 42 °C After soaking in water for 8 hours, remove the persimmon peel for later use;

[0043] (2) putting the peeled persimmons described in step (1) into a drum punching machine for puncturing, then putting them into a vacuum microwave drier for drying until the water content of the persimmons is within 55%; wherein, The microwave power density of described drying is 0.6w / g, and vacuum degree is 65KPa;

[0044] (3) Put the dried persimmons in step (2) into a softener and soak them for 30 minutes under vacuum conditions, and then soak them for 6 hours under normal pressure; wherein, ...

Embodiment 3

[0053] A kind of preparation method of sulfur-free persimmon, comprises the following steps:

[0054] (1) Choose ripe and plump persimmons with hard flesh and no mechanical damage or wormholes as raw materials. Put the persimmons into an ethanol solution with a volume concentration of 71% and soak them for 4 minutes under 70KHz ultrasonic conditions. After taking them out, immerse them in a 39°C refrigerator After soaking in water for 7.5 hours, remove the persimmon peel for later use;

[0055] (2) putting the peeled persimmons described in step (1) into a drum punching machine for puncturing, then putting them into a vacuum microwave drier for drying until the water content of the persimmons is within 52%; wherein, The microwave power density of described drying is 0.5w / g, and vacuum degree is 63KPa;

[0056] (3) Put the dried persimmons in step (2) into a softener and soak them for 25 minutes under vacuum conditions, and then soak them for 5 hours under normal pressure; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com