Ceramic matrix thermocompression impregnated honeycomb body diamond drill bit

A technology of diamond drill bit and honeycomb body, which is applied in the field of diamond drill bit and ceramic matrix hot-pressed impregnated honeycomb body diamond drill bit to achieve the effects of long service life, improved mechanical performance and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

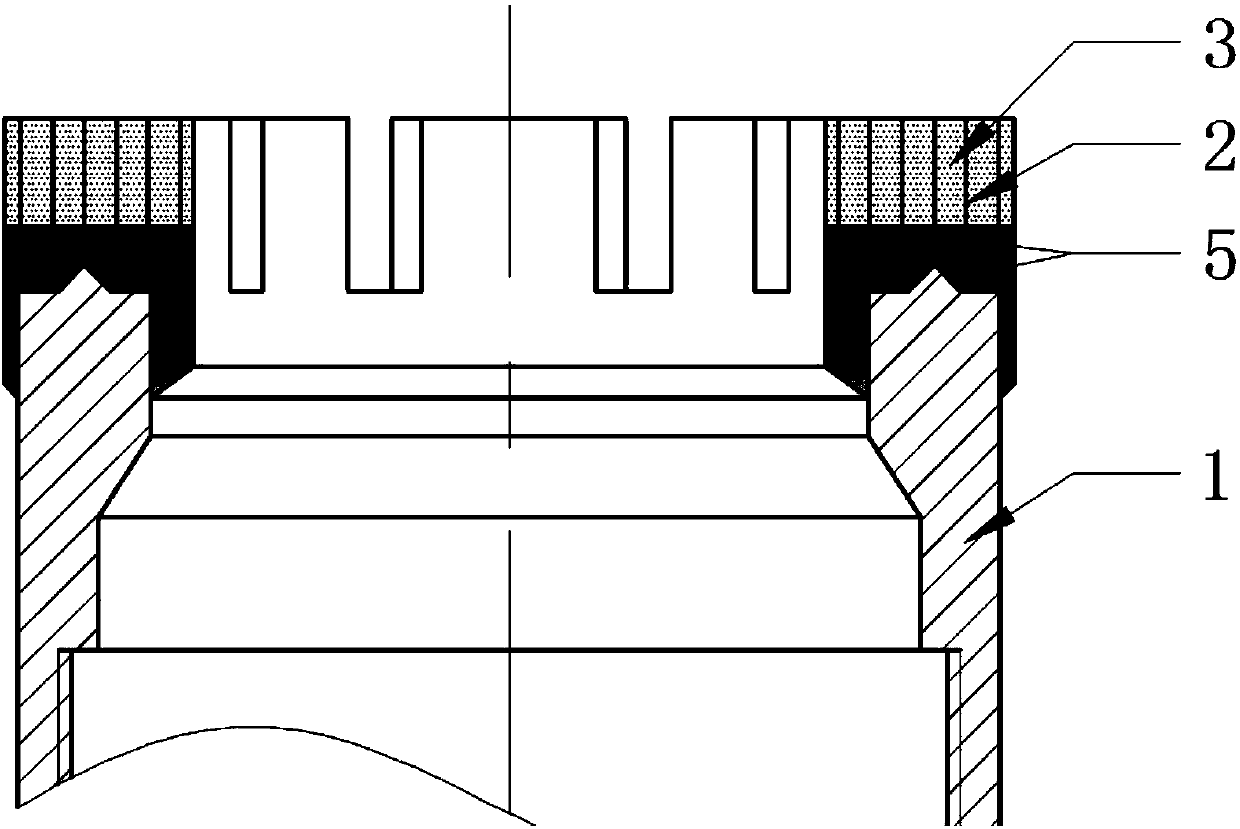

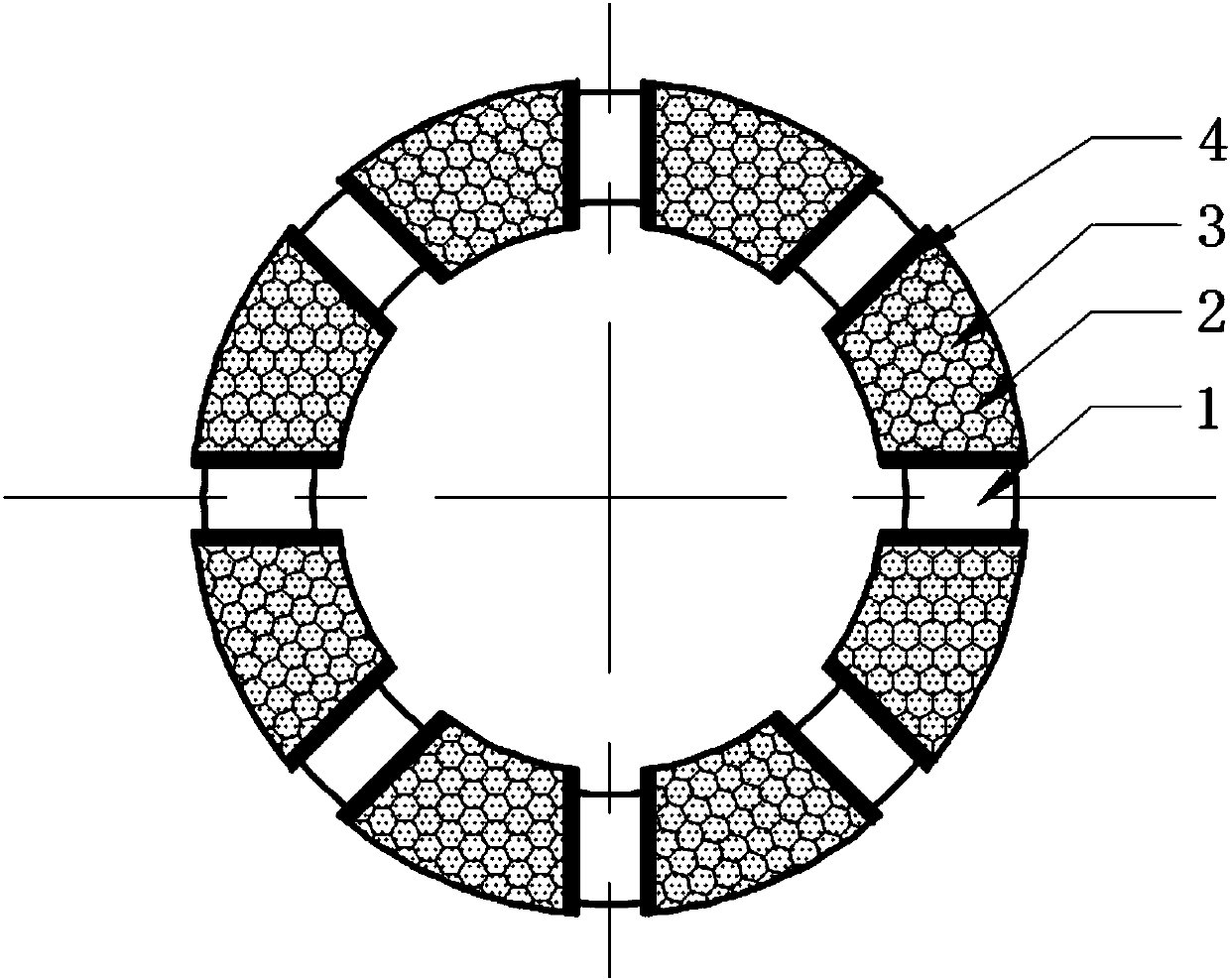

[0018] Such as figure 1 and figure 2 As shown, the present invention discloses a ceramic-based hot-pressed impregnated honeycomb diamond drill bit, comprising a steel body 1 and a working layer 3, a transition layer 5 is provided between the steel body and the working layer, and the working layer The honeycomb body 2 is used as the skeleton, the layer contains ceramic base powder and diamond particles, and nozzle protection layers 4 are arranged on both sides of the honeycomb body.

[0019] The above-mentioned honeycomb body is alloy steel, which greatly improves the bending strength of the ceramic-based working layer. Compared with the working layer without using honeycomb body as the skeleton, its bending strength rises from 100MPa to 800MPa, which meets the strength requirements of the drill bit.

[0020] The above-mentioned transition layer is pure m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com