Electrocatalyst for transition metal core-shell structure film and preparation method thereof

A core-shell structure, transition metal technology, applied in structural parts, electrochemical generators, circuits, etc., can solve problems such as being unsuitable for large-scale industrial production, multiple by-products, and high preparation temperature, achieving low cost and increasing surface area. , the effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0034] 1) Clean and dry the substrate; specifically, soak the substrate in HF acid solution (concentration 1%) for 5-15 minutes to remove surface oxides; then place the substrate in acetone solution for ultrasonic cleaning for 10-30 minutes , remove the oil on the surface of the substrate; then put the substrate in alcohol and ultrasonically clean it for 10-30 minutes to remove the organic matter on the surface of the substrate; finally, ultrasonically clean the substrate in deionized water for 10-30 minutes, take it out and put it in a drying box Dry at 30-50°C for 1-2 hours.

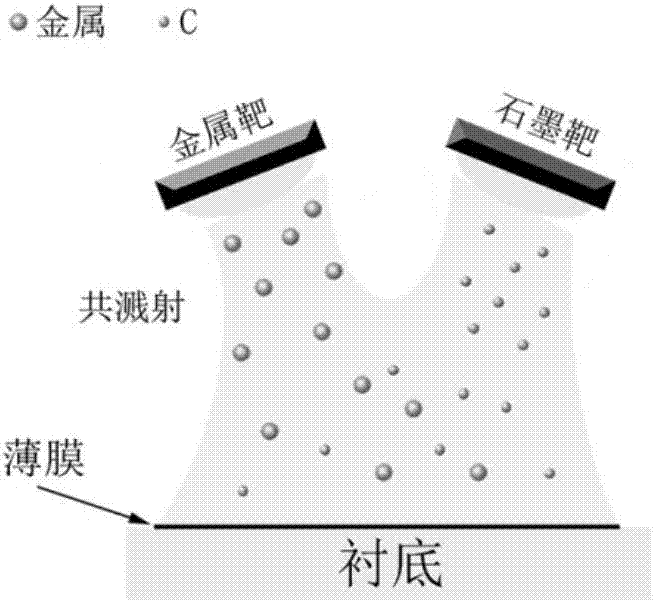

[0035] 2) Using magnetron sputtering equipment, put the cleaned and dried substrate into the vacuum chamber of the magnetron sputtering device, adjust the deposition angle to 45°, and the distance between the target and the substrate to be 100mm. The body is evacuated to 5×10 -4 Below Pa.

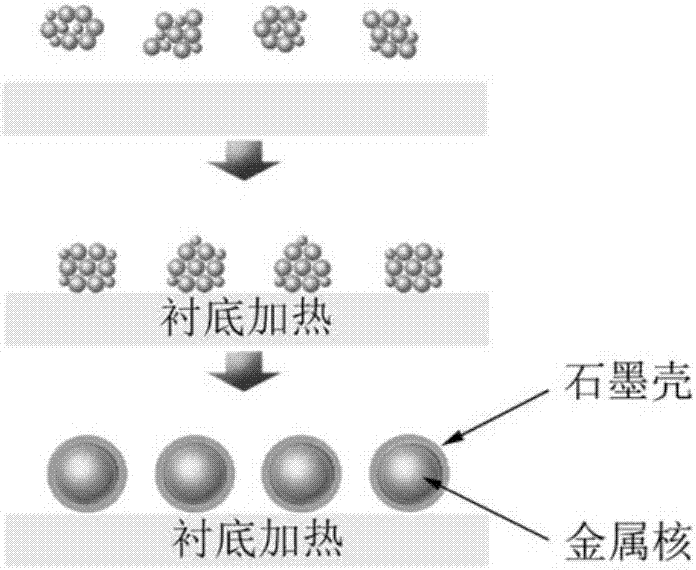

[0036] 3) Preset the substrate temperature to 250°C; after the substrate temperature rises to the preset temper...

Embodiment example 2

[0040] The substrate temperature in step 3) of Embodiment 1 is preset to 450° C., and the rest of the steps are the same as Embodiment 1. Under this condition, no core-shell structure was formed, and the Figure 6 It can be seen that the half-wave potential and initial potential obtained by the test are respectively -0.5V and -0.18V, and the electron transfer number is 3.59.

[0041] The above examples 1-2 are negative examples, because the pre-set temperature of the substrate is unreasonable, finally no sample with core-shell structure was obtained. The oxygen reduction catalytic performance of the product is poor

Embodiment example 3

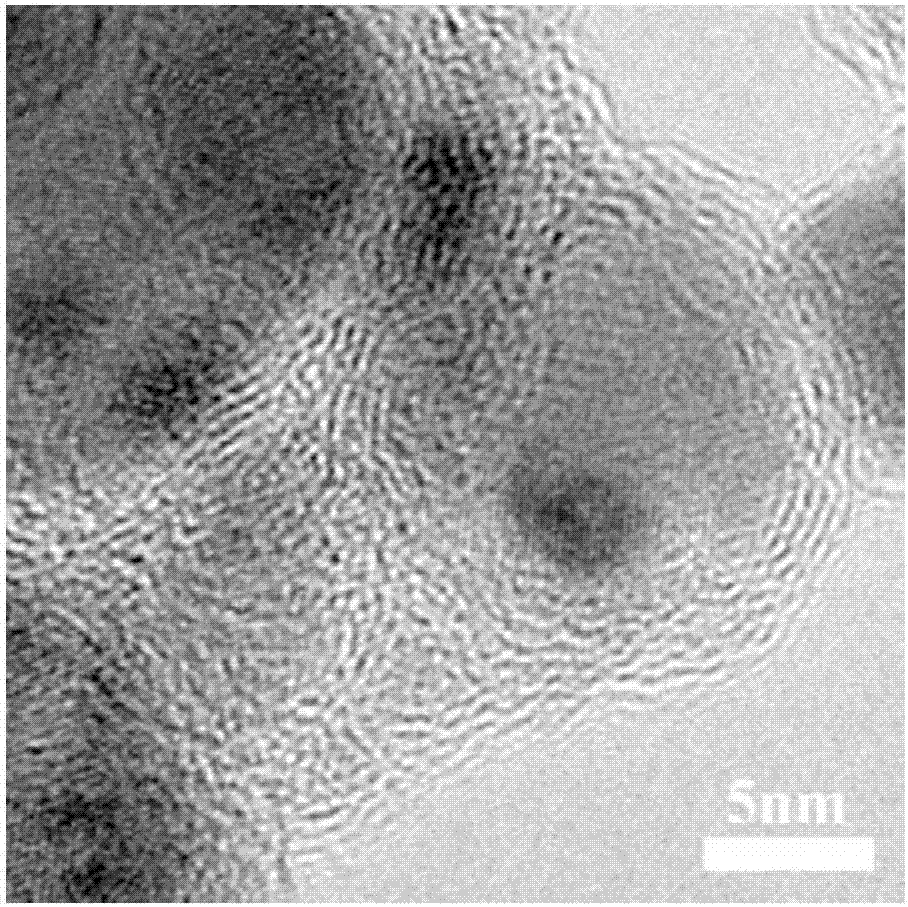

[0043] The substrate temperature in step 3) of Embodiment 1 is preset as 650° C., and the rest of the steps are the same as Embodiment 1. Transmission electron microscopy of the resulting product was as image 3 shown by image 3It can be seen that the Cu@N-C core-shell structure film catalyst was prepared under the conditions of this example, the size of the metal core was 5-15 nm, the number of graphite shell layers was 3-5 layers, and the atomic percentage contents of Cu, C, and N elements were respectively: 22.81at%, 71.21at%, 5.98at%, and the film thickness of the thin film catalyst is 600nm.

[0044] The linear sweep voltammogram of the sample prepared in this embodiment to the oxygen reduction reaction is as follows Figure 6 shown by Figure 6 It can be seen that the half-wave potential and initial potential obtained by the test are -0.24V and -0.06V, respectively, which are close to -0.17V and -0.06V of the commercial Pt / C catalyst. The electron transfer number is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com