Lithium ion battery silicon doped carbon porous composite film and preparation method thereof

A lithium-ion battery, composite film technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low reversible capacity, and achieve the effects of good cycle performance, improved cycle stability, and large specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

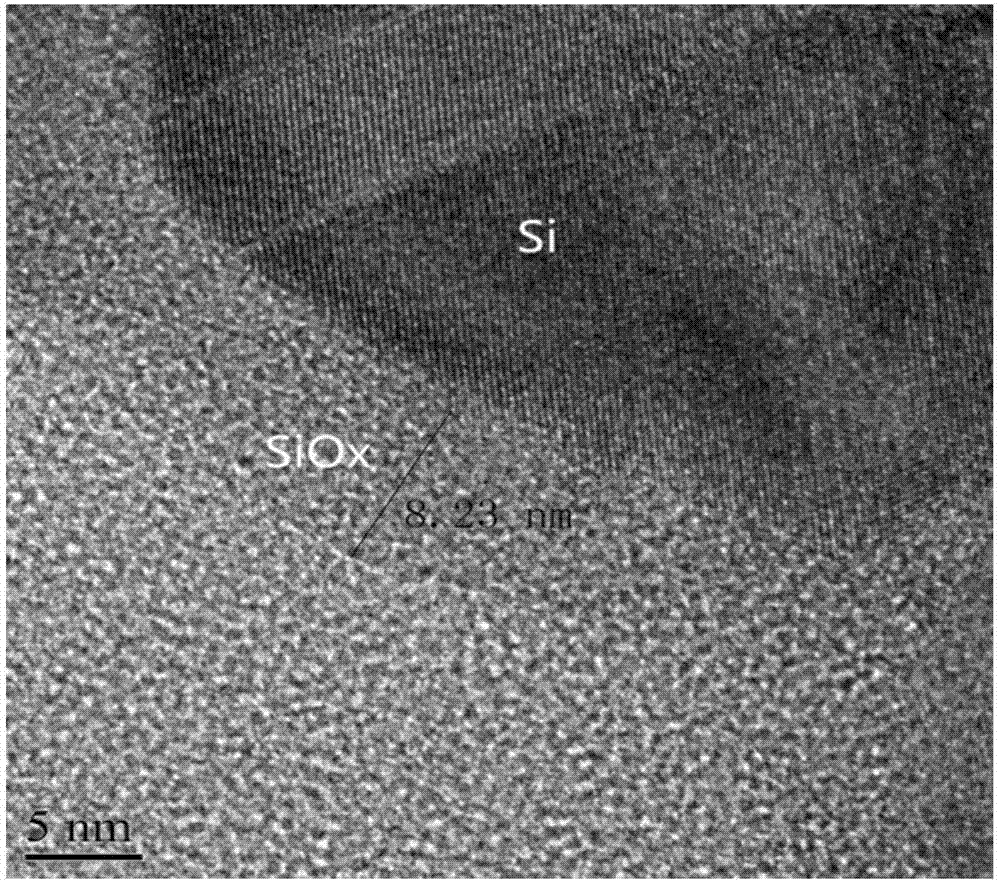

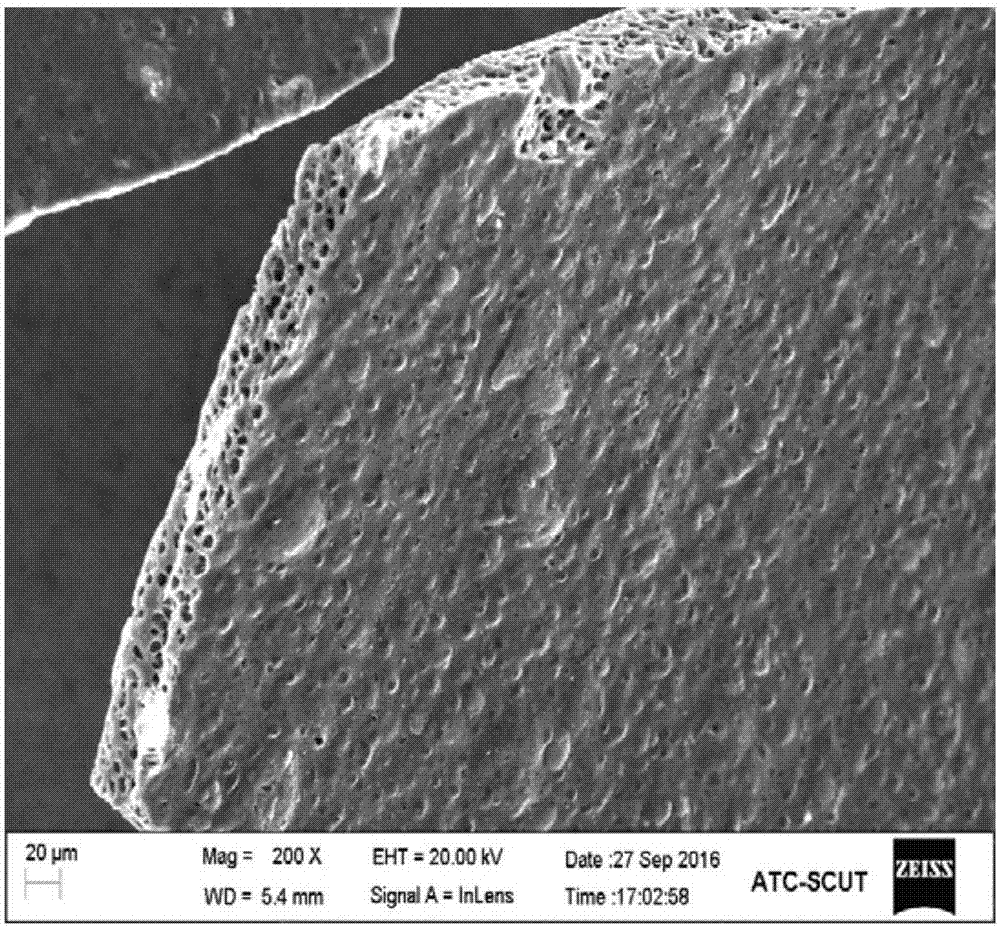

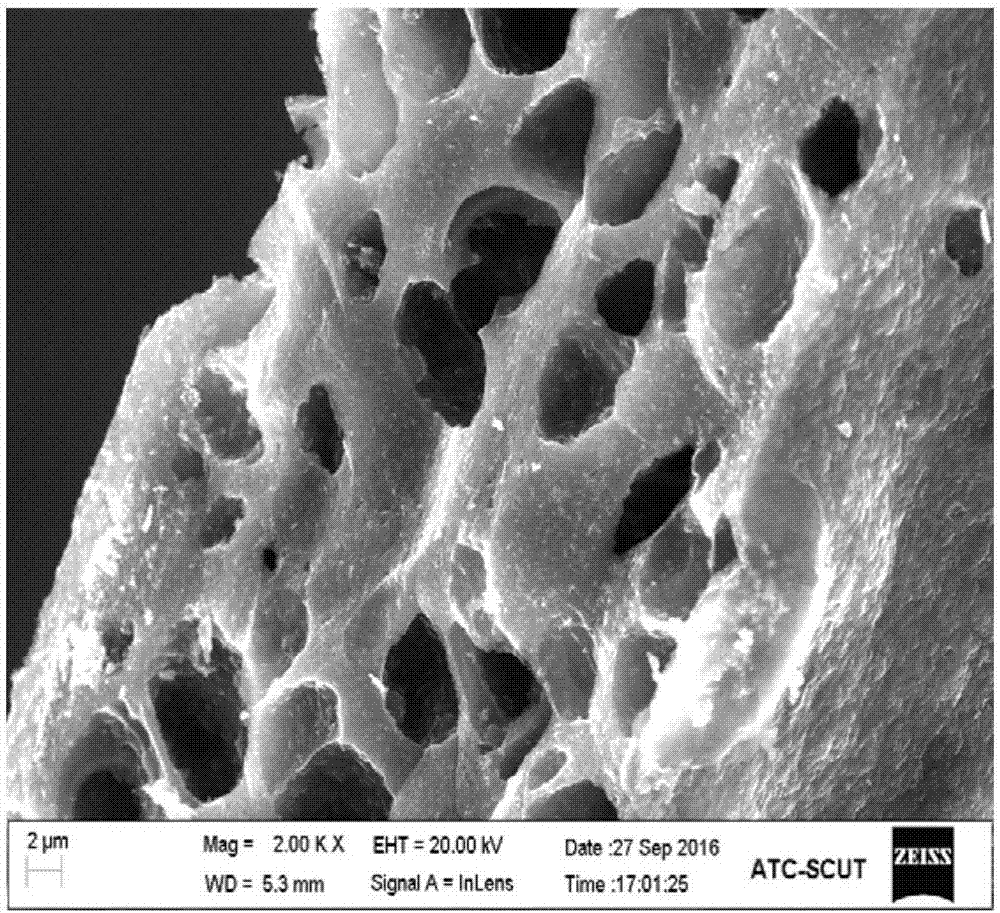

[0035] A silicon-doped carbon porous composite film for a lithium-ion battery is prepared through the following steps:

[0036](1) Weigh 3 parts by mass of 100nm elemental silicon and heat-treat it at 800°C for 10 minutes;

[0037] (2) Add the oxidized elemental silicon obtained in step (1) to 60 parts by mass of absolute ethanol, and after ultrasonic dispersion for 60 minutes, continue to add 10 parts by mass of deionized water and 0.8 parts by mass of γ-(2,3 -Glycidoxy)propyltrimethoxysilane, heated to 40°C, reacted for 4h, centrifuged and dried to obtain modified elemental silicon;

[0038] (3) Add 6 parts by mass of polystyrene to 25 parts by mass of dimethylsulfoxide, heat at 60°C for 0.5h, the mixed solution is in a clear and viscous state, continue to add 0.1 parts by mass of benzoic acid to the mixed solution, step ( 2) The obtained modified elemental silicon was reacted for 6 hours to make a uniform mixed solution, and a 100 μm film was coated on a glass plate with a...

Embodiment 2

[0044] A silicon-doped carbon porous composite film for a lithium-ion battery is prepared through the following steps:

[0045] (1) Weigh 25 parts by mass of 30nm elemental silicon and heat-treat it at 400°C for 1 min;

[0046] (2) Add the oxidized elemental silicon obtained in step (1) to 20 parts by mass of absolute ethanol, and after ultrasonic dispersion for 15 minutes, continue to add 3 parts by mass of deionized water and 0.1 part by mass of γ-mercaptopropyl trimethyl to the mixed solution Oxysilane, heated to 70°C, reacted for 8 hours, centrifuged and dried to obtain modified elemental silicon;

[0047] (3) Add 30 parts by mass of polyvinylpyrrolidone to 65 parts by mass of N,N-dimethylformamide, heat at 100°C for 3.5h, the mixed solution is clear and viscous, continue to add 25 parts by mass of p-benzene Diformic acid and the modified elemental silicon obtained in the above step (2) were reacted for 10 hours to make a uniform mixed solution, and a 100 μm film was coat...

Embodiment 3

[0051] A silicon-doped carbon porous composite film for a lithium-ion battery is prepared through the following steps:

[0052] (1) 14 parts by mass of 50nm elemental silicon were heat-treated at 600°C for 5 minutes;

[0053] (2) Add the oxidized elemental silicon obtained in step (1) to 40 parts by mass of absolute ethanol, and after ultrasonic dispersion for 37 minutes, continue to add 6.5 parts by mass of deionized water and 0.4 parts by mass of γ-aminopropyl tris Ethoxysilane, heated to 60°C, reacted for 6h, centrifuged and dried to obtain modified elemental silicon;

[0054] (3) Add 25 parts by mass of polyacrylonitrile to 45 parts by mass of N,N-dimethylacetamide, heat at 80°C for 2 hours, the mixed solution is in a clear and viscous state, continue to add 2.5 parts by mass of polyethylene glycol to the mixed solution 1. The modified elemental silicon obtained in the above step (2) was reacted for 8 hours to make a uniform mixed solution, and a film of 100 μm was coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com